[Razzing]

OK, I hope you guys are up for a little razzing today....! :big:

Every hobby/career/venue has a few things quirks that drive a guy crazy. lol.

Being into model airplanes, I find people will spend 30 hours, and 4 times as much money, making something, or will use something totally inferior and lame, even when there is a product that is reasonably priced, and performs flawlessly. And it drives you crazy watching it...lol. :big:

That whole, lead a horse to water dealio...lol.

For example: R/C model airplane quirk.... A guys spends 1000 hours and $2000 dollars building a museum scale airplane. And he won't buy the $600 dollar engine that runs good, and he modifies a weed whacker engine that he got for $2 at a yard sale, with inevitable results...lol

Come ooooon man! ...OR, they will buy the most expensive engine, and put the cheapest fuel and glow plugs they can find into it....

I'm a builder, and I'm guilty too, but there are some things that just don't size up to the real deal...

This one has driven me nuts for 20 years! I've seen hand made wavey holders, zig-zag holders, V-holders, and sets of holders that take up 3 drawers in the tool box! I've now seen packing peanuts, old foam, and springs bound to shoot you in the face when least expecting it.... lmao.... :big:

I don't know how many people I've shown these to over the years, and EVERYBODY things they are SOOOOO COOOL!... But, NOBODY, and I mean NOBODY EVER buys them, because their packing peanuts, and cardboard, and clay, and bubble gum works just fine!

I've never even seen ANYBODY who owns them besides ME!

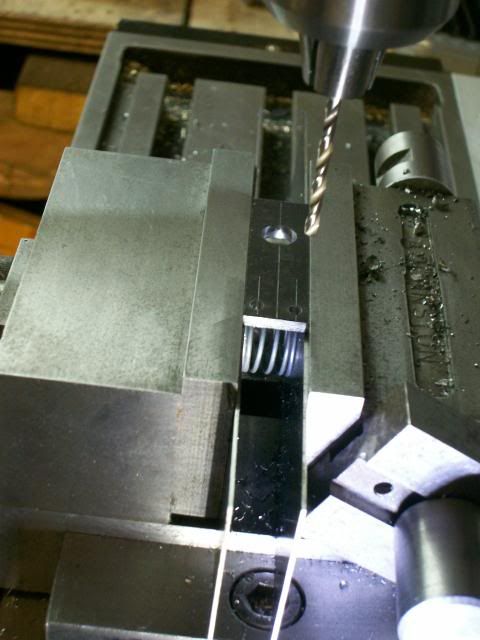

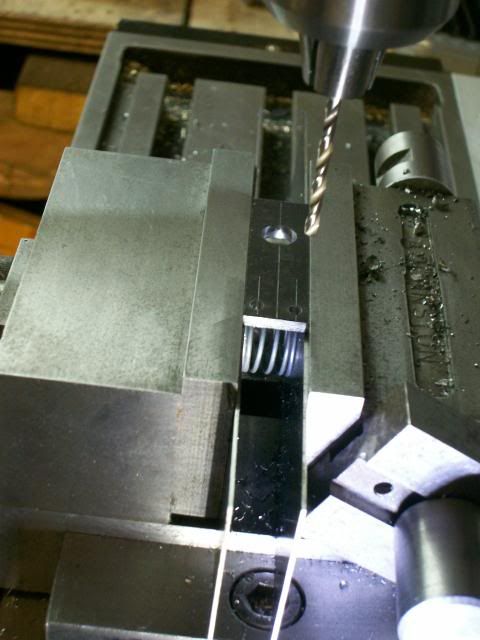

I can zip from 1/4 inch to 7 1/2 inches and never touch the parallels! I can open and close the vice, swap parts, and run 6000 tapped holes, and never touch the parallels. I can clamp a part on the one inch sides, and rotate it to the 6 inch sides and never, ever, touch the parallels.

Granted, once Kurt bought the patent, the price doubled, but they are worth every penny! I mean, if you can spend thousands on a mill, and many hundreds on a Kurt vice, you really SHOULD buy the one thing that makes life this much easier! Even if you bought a vice at a yard sale... Come OOOON, at least make it easy to use, at ANY opening width!!! lol.

But, by all means, don't stop, because I get some realllly good belly laughs out of this topic. I have for years, and will for years, of that I have no doubt! :big: :big: :big:

Please, continue! This is some funny shizznik! lol

Stubborn! ;D

http://www1.mscdirect.com/CGI/NNSRIT?PMPXNO=12576867&PMT4NO=74976517

[/razzing]

Cheers!