I am interested in trembler coils, similar to that used in Model T fords. In a conventional points style ignition, you get one spark at the plug when the points open. With a trembler coil system, you get a series of sparks whenever the points are closed. There are a ton of "How to" articles on building your own trembler coil on Youtube, and it seems that I already have most of the components (a 12 volt coil and a condenser.) It seems that all I need to buy is a special relay, which is commercially available. Does anyone have more information pro or con about these trembler coil systems?---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trembler Coils--(Constant spark)

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Brian,

I built one of the “buzz coil” systems you’re describing as an alternate to the original Model T coil I have for my “kitchen sink” engine. Performance wise, it is every bit as hot as the model T coil and ran the engine well.

Cheap to make and parts are readily available at any automotive parts store.

John W

I built one of the “buzz coil” systems you’re describing as an alternate to the original Model T coil I have for my “kitchen sink” engine. Performance wise, it is every bit as hot as the model T coil and ran the engine well.

Cheap to make and parts are readily available at any automotive parts store.

John W

This brings up an interesting point. On conventional points style ignitions, it is the opening of the points which breaks the circuit and causes the sparkplug to fire. On a "trembler coil" ignition, the sparks begin when the circuit is "closed" and the sparks stop when the circuit is opened. This is the exact reverse of how a conventional points ignition system works. I know what an ignition cam for a conventional points system looks like. I can only assume that the old hit and miss engines that used trembler coils must have had an ignition cam that worked in the exact opposite manner. Does anybody have a picture of what the cam looked like on the old hit and miss engines?.

Brian,

The cam would be a disc with a cutout where the points would be closed, I would say between 5-10deg, and set for where you would like it to fire. Vintage spark model aircraft engines operate similar, the points are only closed for a short duration as to not over heat the coil or drain the batteries. they only operate on 3 volts.

Cheers

Andrew

The cam would be a disc with a cutout where the points would be closed, I would say between 5-10deg, and set for where you would like it to fire. Vintage spark model aircraft engines operate similar, the points are only closed for a short duration as to not over heat the coil or drain the batteries. they only operate on 3 volts.

Cheers

Andrew

- Joined

- Dec 31, 2010

- Messages

- 784

- Reaction score

- 195

Contact Roy he makes a version of your system that is multi-spark. I believe it uses the same sensor arrangement except the sparks start when the hall sensor is covered by the magnet and stop when it is cleared. A small adjustment in the timing is required to get the sparks starting at TDC or thereabouts (hall activated at TDC)

With that said, if your engine doesn't even try to pop even once in a while your problem is likely not the ignition system and you should look for other issues. I presume your other engines all ran using a single spark from an ignition coil and points. So you might ask why this one needs multi-spark.

On another tact. Have you tried a spark tester in series with your spark plug wire. Or just pull the wire off and hold it very close but not touching the plug top. If you have a spark there then it is also sparking inside the engine at the spark plug gap (Or it's shorting out inside).

With that said, if your engine doesn't even try to pop even once in a while your problem is likely not the ignition system and you should look for other issues. I presume your other engines all ran using a single spark from an ignition coil and points. So you might ask why this one needs multi-spark.

On another tact. Have you tried a spark tester in series with your spark plug wire. Or just pull the wire off and hold it very close but not touching the plug top. If you have a spark there then it is also sparking inside the engine at the spark plug gap (Or it's shorting out inside).

Last edited:

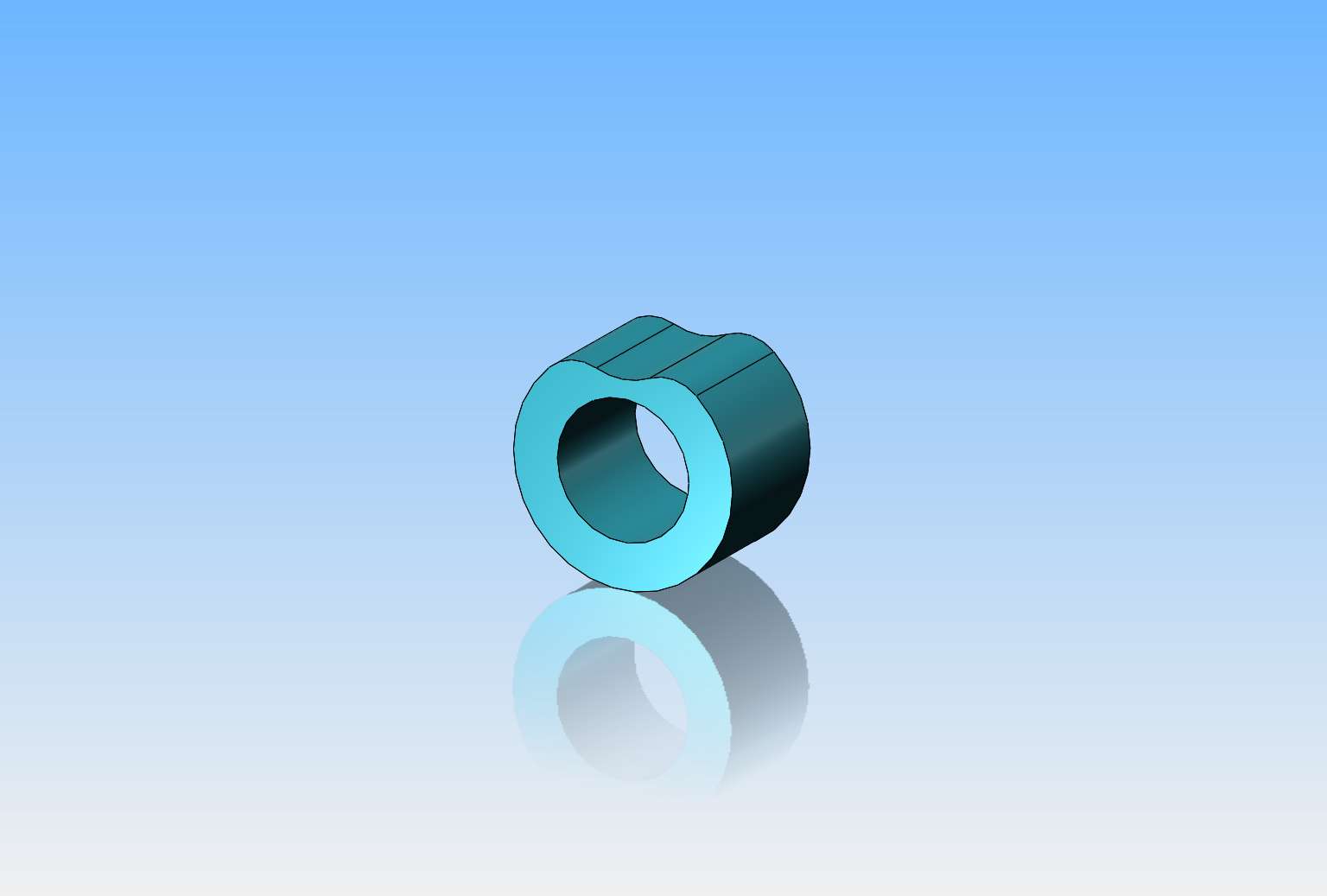

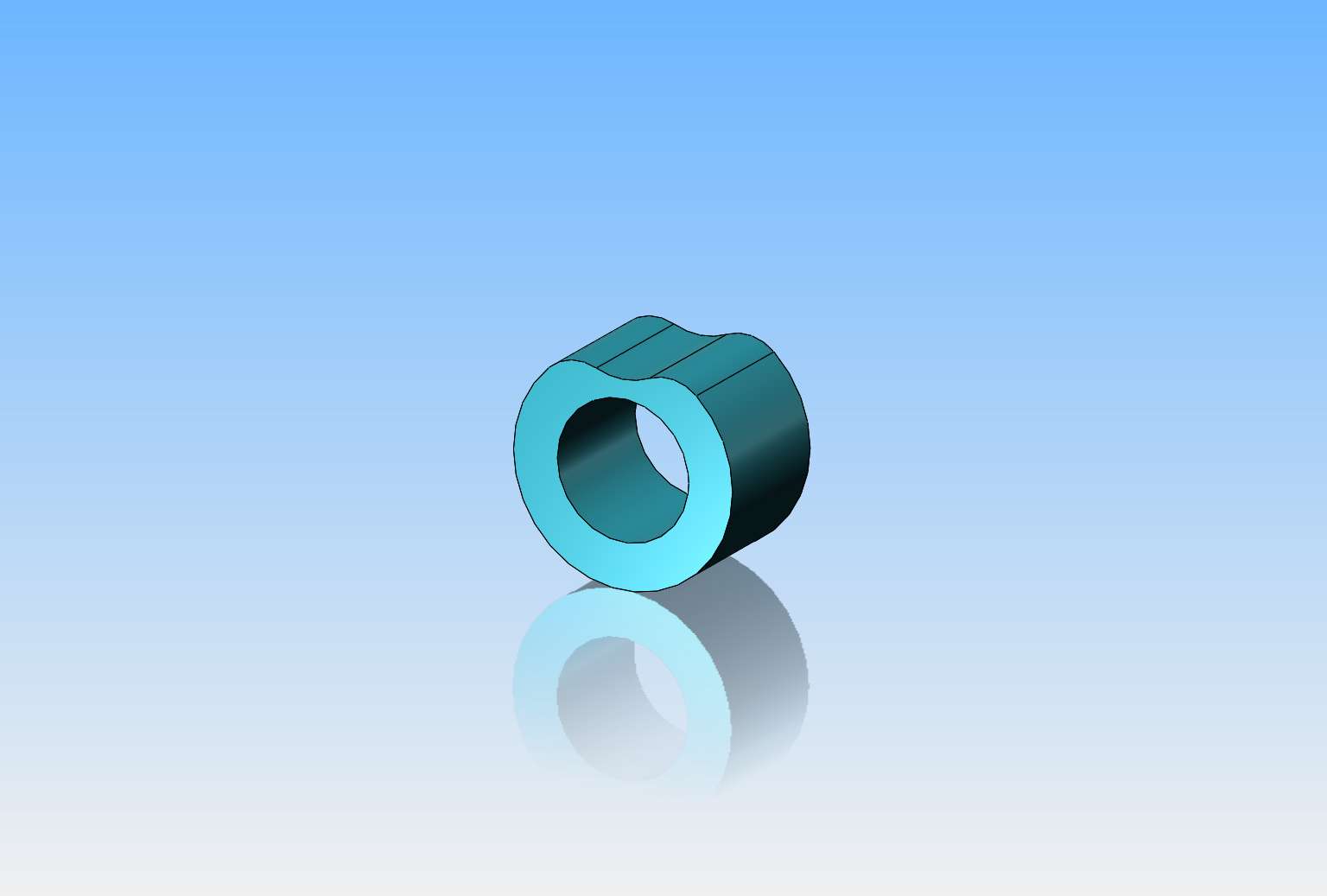

Going boldly where I've never been before---If a trembler coil system produces sparks only when the points are closed and the current is allowed to flow---then you need a cam that is reversed from what a conventional cam is like on a conventional ignition system. You would want the cam to hold the points open most of the time, and only allow the points to close momentarily when you want it to fire. So---This is my shot at a reverse cam lobe.

Not if one uses a simple transistor inverter on the signal from the points.then you need a cam that is reversed from what a conventional cam is like on a conventional ignition system.

bluejets---You are probably right. I know very little about electronics.---Brian

Brian, That looks about right, should work well with points

Cheers

Andrew

Cheers

Andrew

- Joined

- Jul 16, 2007

- Messages

- 3,003

- Reaction score

- 1,065

Brian, on the hit and miss engines that used 'buzz coils' they had a cam that had a lobe on it much like a valve cam lobe. Naturally it is mounted to the timing gear so therefore is the ground side of the equation. The contact was nothing more than a strip of, I'm assuming, phosphor bronze, that was insulated from the engine. The strip had power attached to it. When the cam cam around it brushed the strip and therefore completed the circuit. The problem I see with your cam is that the points probably won't like falling into a groove. It will work but will be hard on the point rubbing block.

I quite agree, at a speed a few tens rpm it is probably fine, but at a speed a few hundred, thousands rpm, it will be an issue to consider.The problem I see with your cam is that the points probably won't like falling into a groove. It will work but will be hard on the point rubbing block.

Yep, I built my ignition system on the Kitchen Sink Engine with a flattened .223 case and a flat spring with a single roll pin as the cam! Crude as hell but it works.

John W

John W

Thanks guys.---Brian

Yes Jason--You're right. All the cam heeds is a flat side.

This morning I am down in my shop wiring up a trembler coil, based on a wiring diagram I found on the internet. It uses a standard 12 volt automotive coil and a five pin relay, along with a condenser and an on/off switch. I'm happy with my results, and will be trying this ignition system out on the model i.c. engine I have recently built.

Similar threads

- Replies

- 25

- Views

- 4K