C

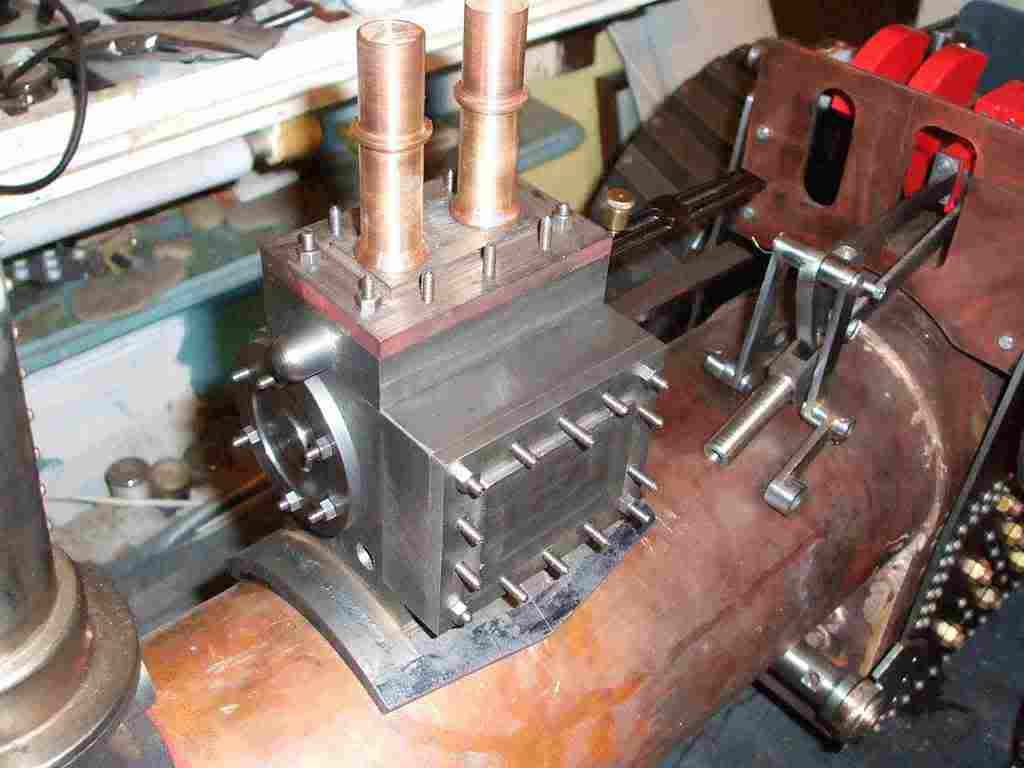

compound driver

Guest

Hi

Just a few pictures of the traction engine not had time to post much more work n such has taken over plus a new grunt to play with too bloody old for tractors and kids.

Cheers kevin

Just a few pictures of the traction engine not had time to post much more work n such has taken over plus a new grunt to play with too bloody old for tractors and kids.

Cheers kevin