And, we're away to the races. Engine seems to run fine, but I haven't hooked up the hit and miss mechanism yet. I'm happy that the engine seems to run very well. The carb I have on the engine right now is a throttled style carb, and if the throttle is wide open, the engine tries to levitate off my desk and nearly scares me to death. It is running at about 1/3 throttle in this video. Next step will be to get the hit and miss mechanism hooked up.---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Time for a new Horizontal Hit and Miss engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I just tried out the hit and miss mechanism, and it works. It engages just fine, but I need a stronger compression spring to disengage it, otherwise the engine just runs down and stops before the current compression spring (out of a ball point pen) returns the lockout lever into the 'run' position.

Brian,

Congrats on another one running, can't wait to see it on hit and miss.

Cheers

Andrew

Congrats on another one running, can't wait to see it on hit and miss.

Cheers

Andrew

Brian,

I always enjoy your write-ups and videos.

You deserve that "hoorah!".

K2

I always enjoy your write-ups and videos.

You deserve that "hoorah!".

K2

I found a stronger spring in my collection, and replaced the ball point pen spring which I previously had as part of my hit and miss mechanism. Now the spring is too strong, and won't allow the engine to go into "hit and miss" mode. The seat which the spring sets in is adjustable, so today I will play with a variety of springs until I find one that is "just right". I was going to make a proper size cylinder oiler and mount it on the engine, but found that I don't have any glass or plastic tube stock on hand, so this morning I ordered a new one from Ebay.

The search for the Goldilocks spring? "This one is just right!"

There should be a way to measure the spring constant and bound the problem, figuring how many grams/cm are too much and how many are not enough, but I honestly don't know how to go about doing that analytically.

There should be a way to measure the spring constant and bound the problem, figuring how many grams/cm are too much and how many are not enough, but I honestly don't know how to go about doing that analytically.

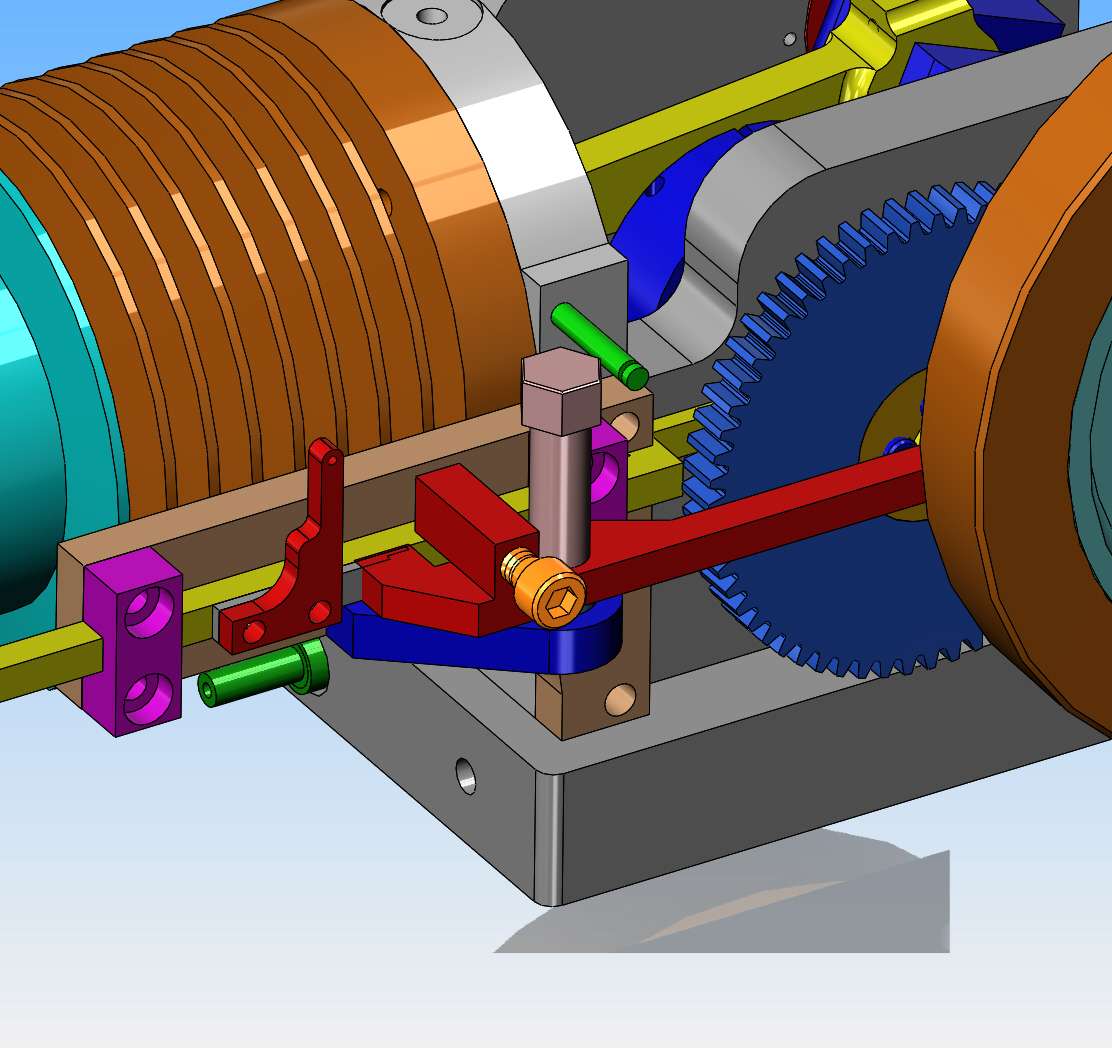

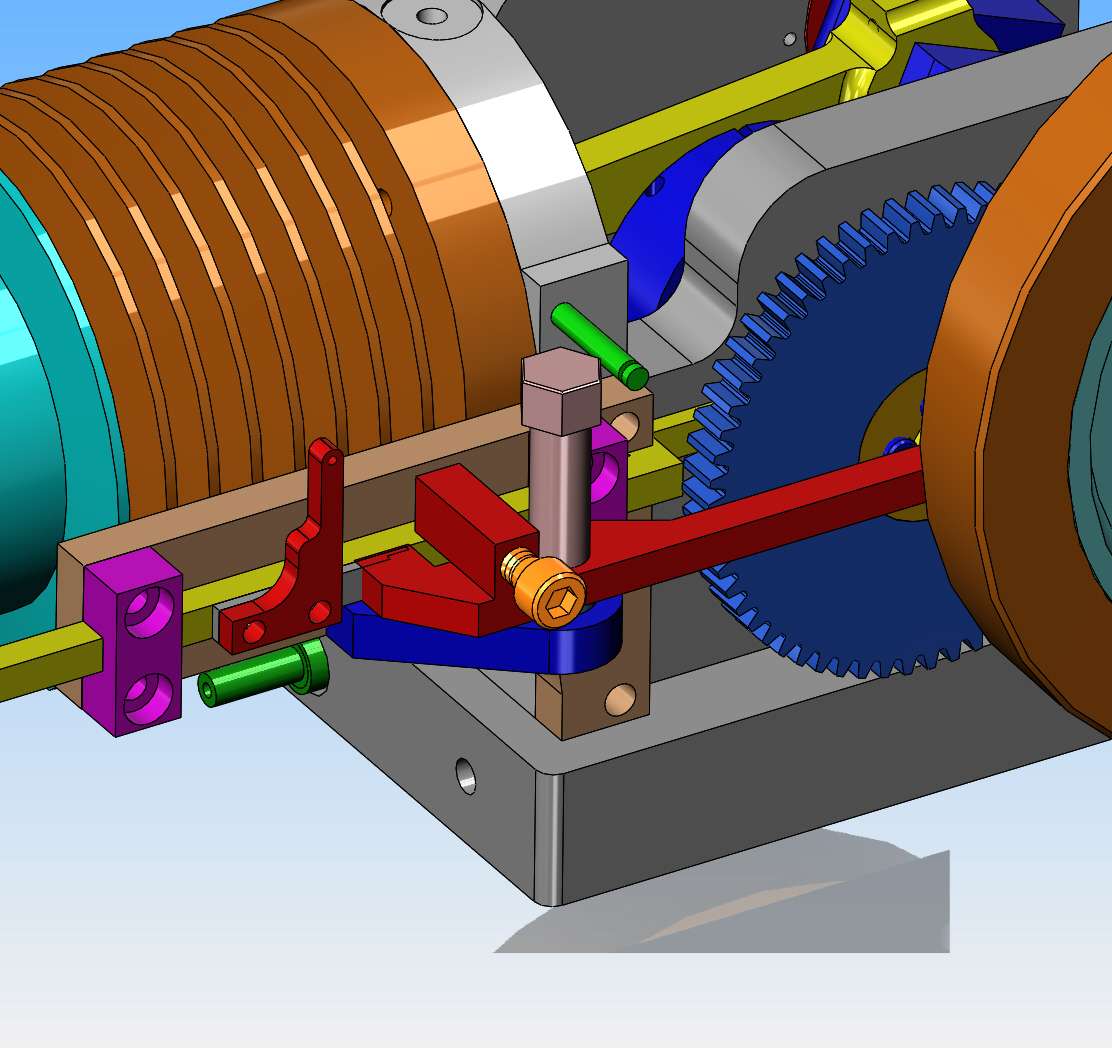

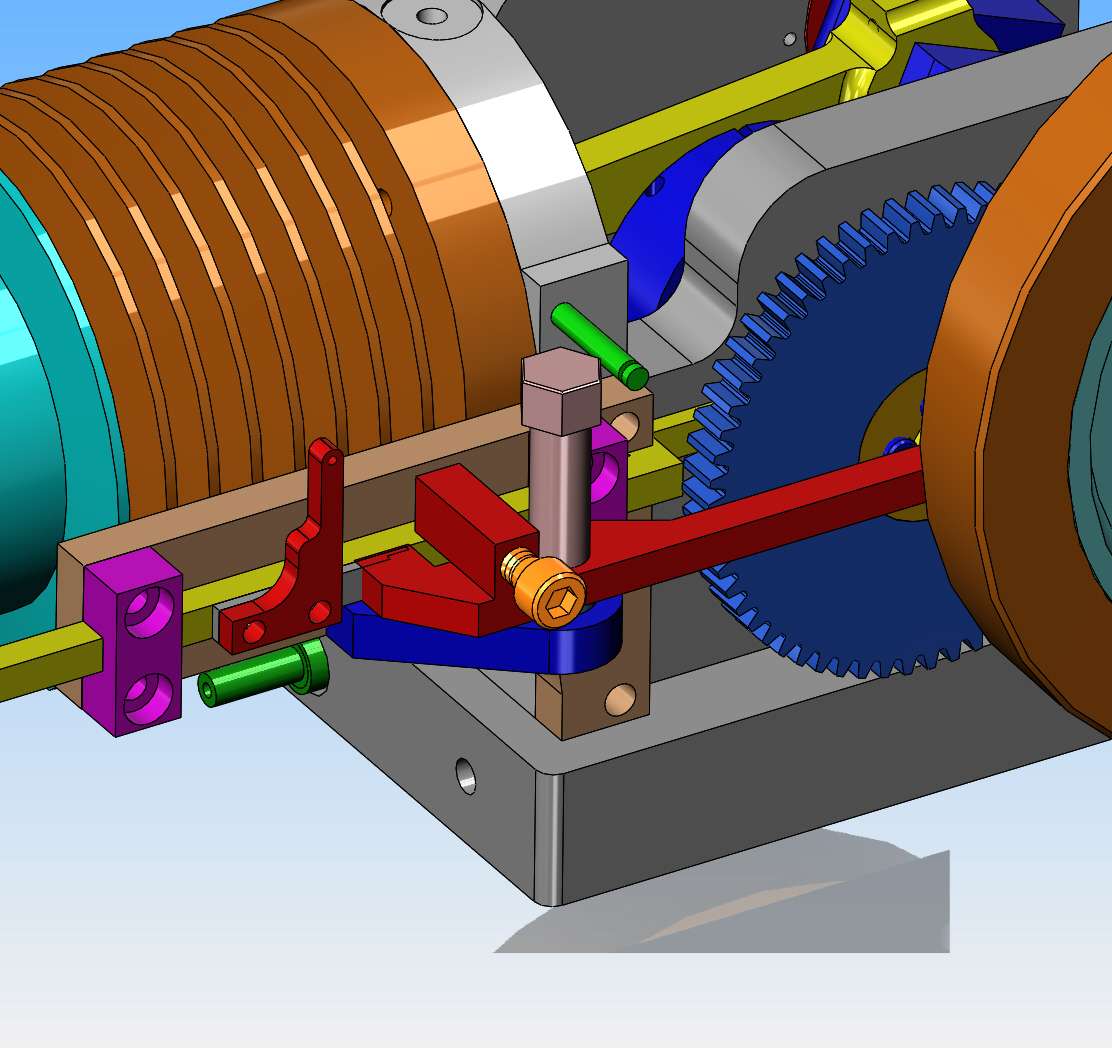

Bob--the engine runs just awesome!!! The spring which counteracts the action of the counterweights sets inside that red square piece with the 1/4" orange capscrew in it. By tightening the capscrew, I can force the spring to put more pressure against the aluminum mounting plate, so I can adjust that capscrew to vary the pressure the spring exerts. That sounds great, but right now I'm having little success with it. I'm going to have to study the mechanism on some full size Hercules engines and see what they did to make the governor disengage.

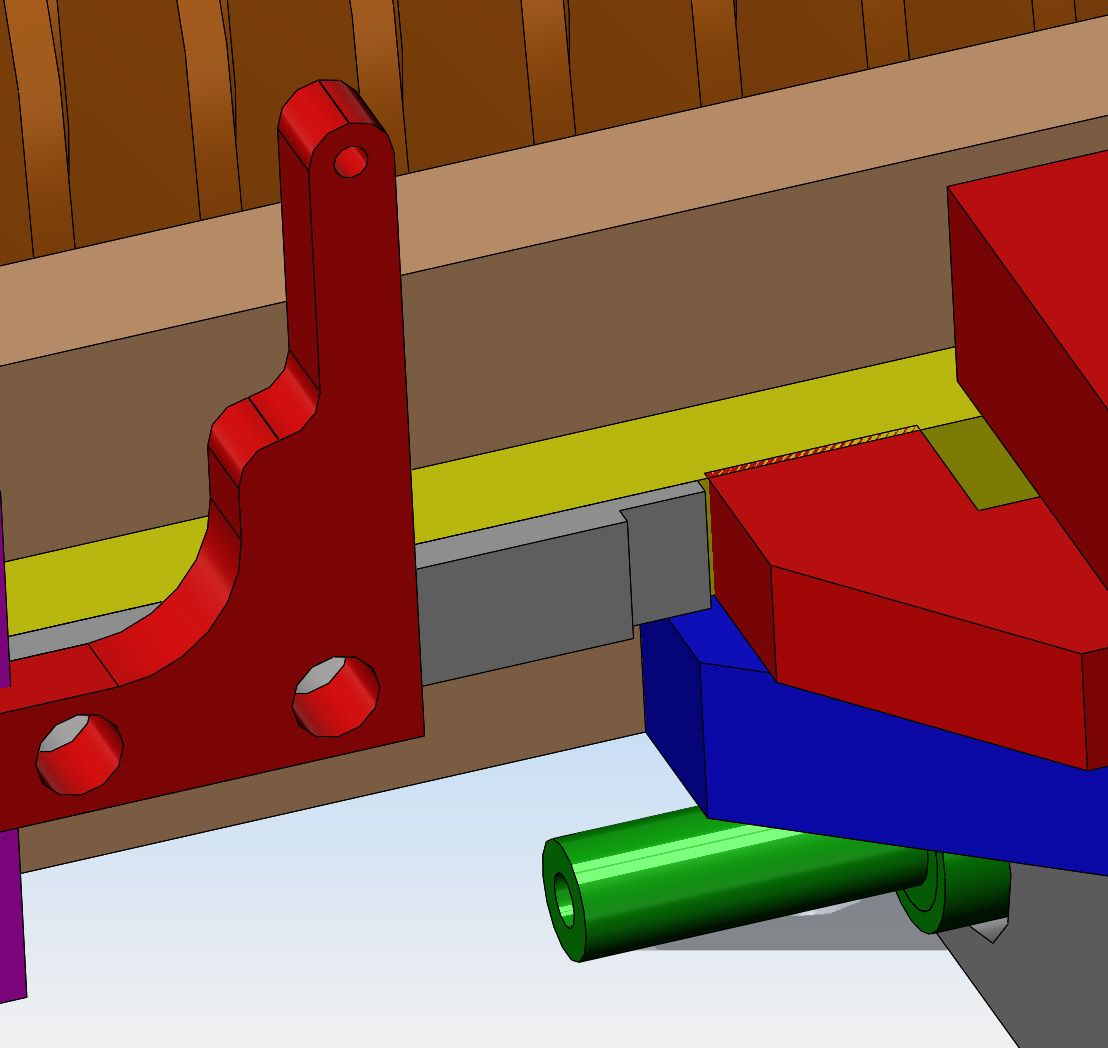

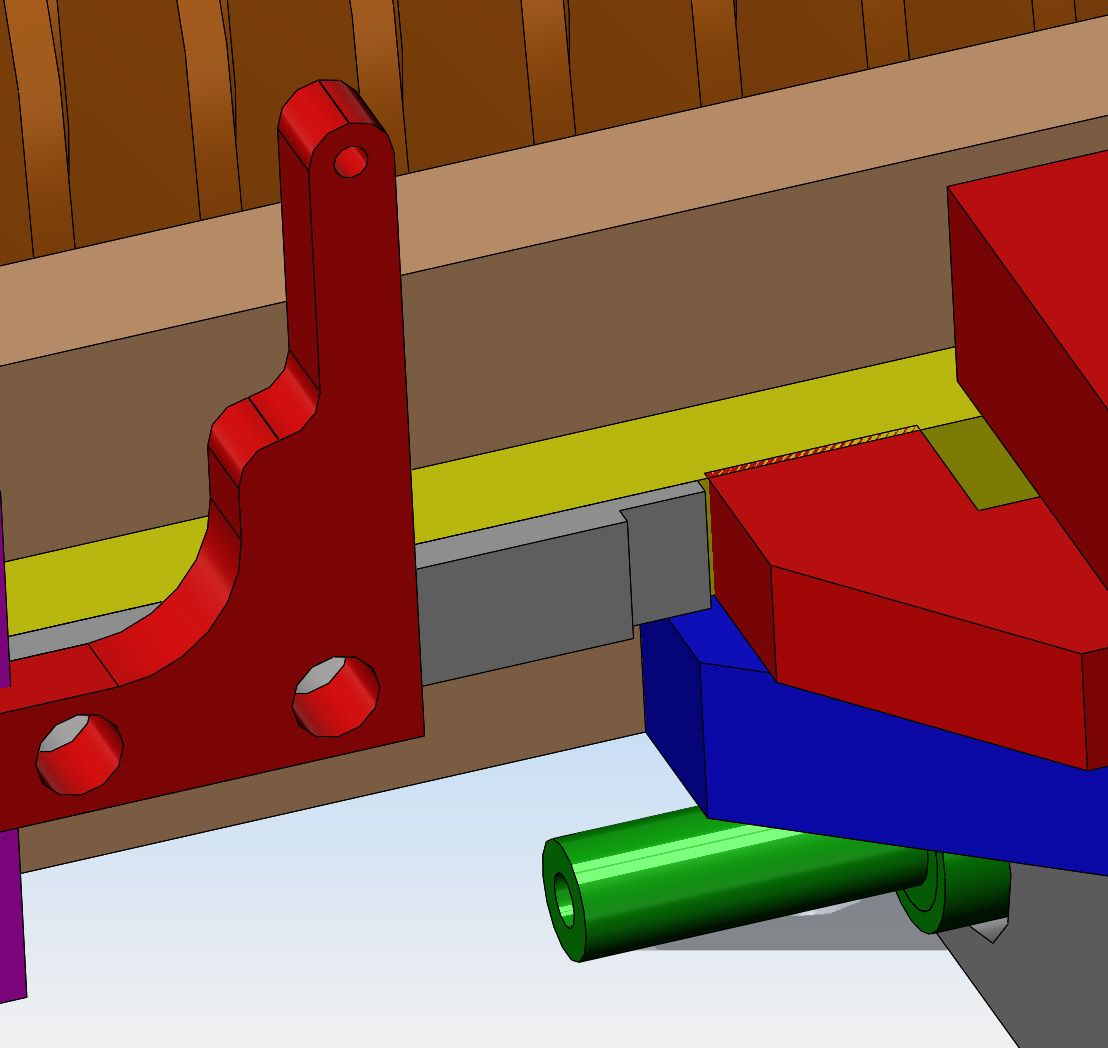

I'm about to pack it in for the day, but here's a thought. The governors work exactly as they are supposed to, and when the engine speeds up, the governor causes an arm to pivot and "catch" under the end of the grey plate which is sandwiched between the red funky shaped plate and the yellow push-rod. In a perfect world, as the engine slowed down, the compression spring buried in the pivoting hit and miss bar would force the end of the hit and miss bar out from under that grey plate, and the engine would fire again. I have tried a few different strength springs, and that doesn't seem to be doing it. The OTHER factor here is how deep that "notch" is that the pivoting hit and miss bar is catching under. I've tried 0.062", and that doesn't work.---it won't disengage. I've tried 0.031" and that doesn't work--it still won't disengage. What next?--Well, the easiest thing for me is to make a new grey bar with an 0.015" step. That is a fairly simple part to make, and I will probably do that later today.

Mike1

Mike1

Brian, your latch will work better if you file a small bevel on the toe of the latch so that it clears the latch stop when the spring pulls it open, similar to the shoot on a lock latch.Bob--the engine runs just awesome!!! The spring which counteracts the action of the counterweights sets inside that red square piece with the 1/4" orange capscrew in it. By tightening the capscrew, I can force the spring to put more pressure against the aluminum mounting plate, so I can adjust that capscrew to vary the pressure the spring exerts. That sounds great, but right now I'm having little success with it. I'm going to have to study the mechanism on some full size Hercules engines and see what they did to make the governor disengage.

Mike1

There is a third factor in play here. If the hit and miss lever fits under the notch when the pushrod is at its extreme extent of travel, then the hit and miss lever is always under pressure, making it difficult to release, and consequently letting the engine run down and die. However, if the hit and miss lever can engage with the pushrod before it reaches the extreme extent of its travel then the exhaust valve will still be held open and the engine will miss, but every time the cam comes around it will bump the pushrod and momentarily remove the pressure from the hit and miss lever, allowing the compression spring to pivot the hit and miss lever and return the governors to the "run" position. I think that may be the answer, and again, I will try that later today.

danallen

Well-Known Member

That is how my Farm Boy works. When the engine is coasting in "miss" mode the push rod moves ever so slightly every time the cam goes around. When the governor retracts the hold open lever there is no resistance.

Big Daddy--I used a carburetor that I made for this one. Yes, I have had excellent results using Chucks carburetor.

I have the engine hitting and missing now. Its doing it in a very fast and frightening way, but it is hitting and missing. If I can just tame it down a little now, then we're good.

Here's a little something you will find interesting. When I designed this engine, I mounted the gas tank as low as possible. I did this because these carburetors which I use don't have a needle and float, so if the gas tank sets higher than the carburetor, they will continually flood themselves. I've been trying to get consistent runs out of the engine today, but the runs were not consistent. In fact, they were all over the place, and I couldn't figure out why.--On a whim, I fully unscrewed the carburetor needle valve and guess what!!!--A steady stream of fuel was peeing out of the carburetor. The gas tank wasn't located low enough in relationship to the carburetor, even though it looked like it was. So--I took a trip out to my main garage, and sawed up a long wedge from a 2 x 6 and mounted the engine and attached gas tank on an angle. Now I know for sure that the gas tank is lower than the carburetor. I will do more trial runs tomorrow.

JohnBDownunder

Well-Known Member

- Joined

- Mar 1, 2012

- Messages

- 110

- Reaction score

- 29

That idea sure beats fiddling around and actually changing the tank position just to see if it helps. At least then you know and can vary the wedge to find the so-called sweet-spot. Love reading your build logs.

Regards,

John B

Regards,

John B

Brian on all the ones I have done the latch does not engage at full travel, it will engage as the valve starts to close so every time the cam comes round it will give the pushrod a slight nudge which releases the latch and then if the weights are still out they will stop the valve closing but if the weights have moved in the latch will get realeased and have time to disengage before the rod comes back off the nudge.There is a third factor in play here. If the hit and miss lever fits under the notch when the pushrod is at its extreme extent of travel, then the hit and miss lever is always under pressure, making it difficult to release, and consequently letting the engine run down and die. However, if the hit and miss lever can engage with the pushrod before it reaches the extreme extent of its travel then the exhaust valve will still be held open and the engine will miss, but every time the cam comes around it will bump the pushrod and momentarily remove the pressure from the hit and miss lever, allowing the compression spring to pivot the hit and miss lever and return the governors to the "run" position. I think that may be the answer, and again, I will try that later today.

Your best bet will be to put slots in your grey plate so that you can loosen the fixings and slide it into different positions to find the sweet spot. It is also usual to angle the latch and latch plate so they lock into place

If you look at my model of the Gade you can see that the pushrod moves every time so the latch disengages lengthways but the governor keeps it pushed in sideways until it is time for the next hit. The longer of the two plates that latch together is slotted for adjustment.

No really great news to report today. I didn't like the engine setting up on an angle, so I machined three 1/2" square aluminum pieces to fit between the base plate and the three vertical plates, and changed my model and drawings to reflect the change. This took care of the gasoline tank being higher than the carburetor. I have had the engine running off and on many times today but I'm still not happy with the consistency of my runs. What I am after here is an engine that runs reasonably slow without the hit and miss lever hooked up. Then I will try lighter springs in the lever return mechanism until I reach a balance point between the rpm of the engine and the rpm at which the lockout lever works. I had it doing that yesterday afternoon, but the engine was doing about 2000 rpm while it was happening.---Very scary--kind of like working on a bomb.--And just for the record, the governor weights don't touch the con rod when the governor engages. I don't think you could get a cats whisker between them, but there are no marks on the con rod nor on the governor weights.

Similar threads

- Replies

- 11

- Views

- 3K

- Replies

- 12

- Views

- 1K

- Replies

- 25

- Views

- 6K