Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

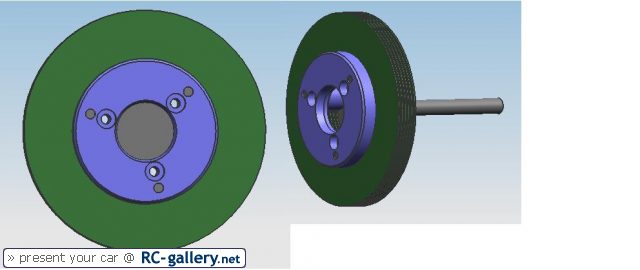

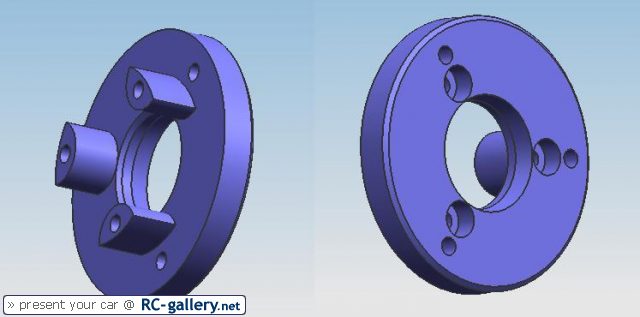

I cast some covers yesterday. They turned out great!!! I'll post some pictures soon.

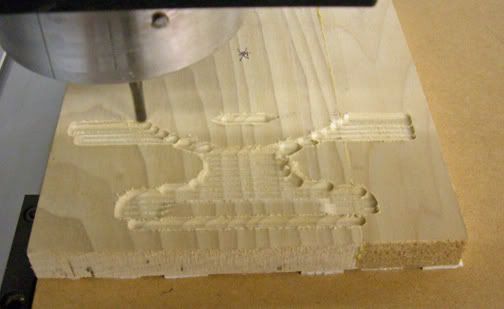

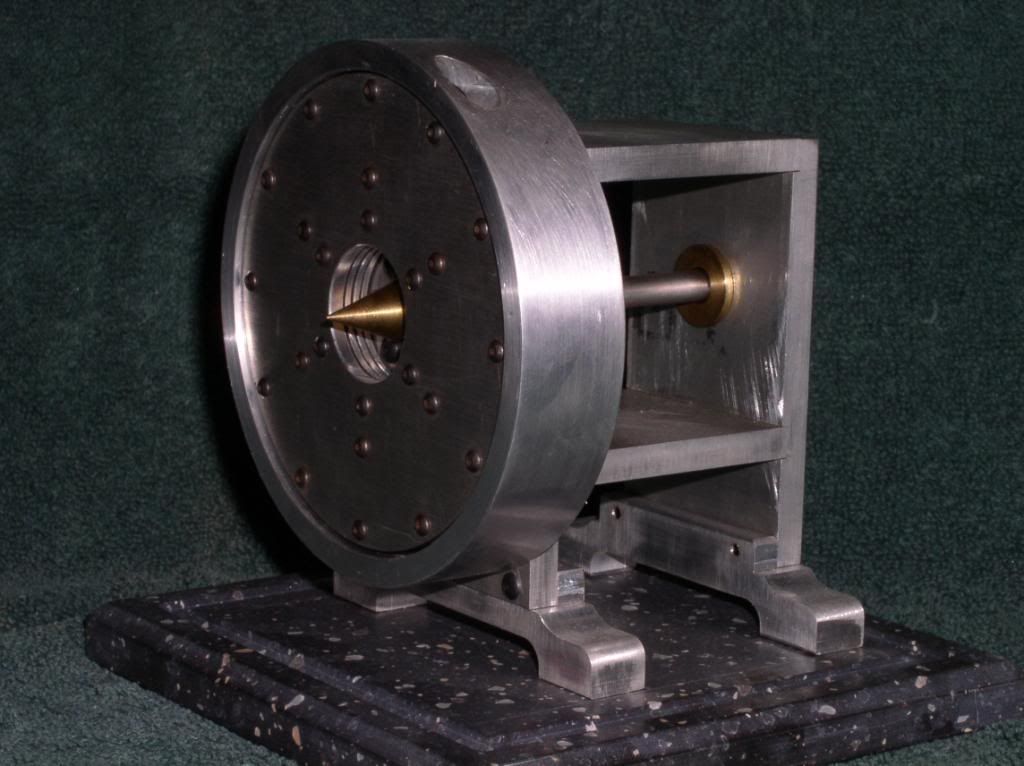

I'm drawing the case up with Mastercam. I was having troubles getting the base like I want it, so I didn't get to machine it yet. I stumped the instructor so he's going to look into it for me. It will look pretty nice when done though.

I'm thinking about making the exhaust cover out of Plexyglass? I think it would look neat to be able to see the discs spinning.

I'm drawing the case up with Mastercam. I was having troubles getting the base like I want it, so I didn't get to machine it yet. I stumped the instructor so he's going to look into it for me. It will look pretty nice when done though.

I'm thinking about making the exhaust cover out of Plexyglass? I think it would look neat to be able to see the discs spinning.