Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

Hey Everyone,

I've been lurking here for a couple of weeks. I like this place.

First I'll introduce myself. I'm a full time Machinist and I love it! I have two lathes at home. A 13" X 60" LeBlond and a South Bend Junior 9" X 48". I have a Enco bench mill and a couple of welders. Ive also been building up a home foundry. The place I work just bought an older CNC mill. They have been sending me to school to learn how to run it. I've built several engines, steam and atmospheric. I've been wanting a Tesla style turbine. I love the way they sound:O).

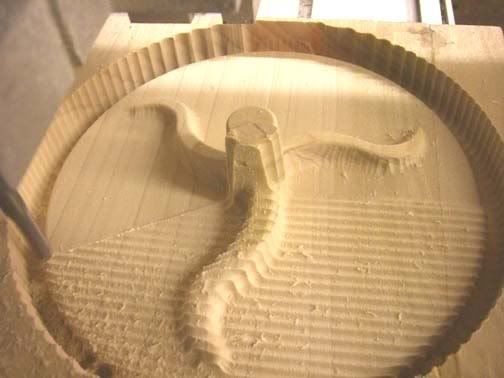

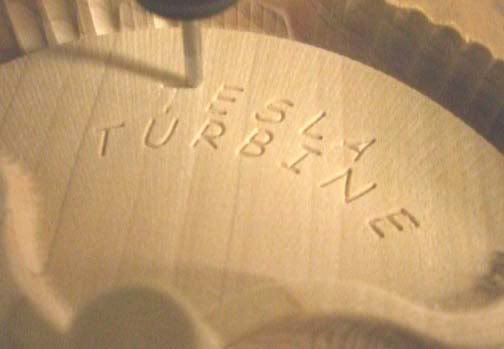

My next project will be some patterns that I've drawn up to build my own Tesla Turbine. I plan on using CD's for the discs and bearings from small RC cars for the shaft. I'm planing on building the patterns on the CNC mill at school. I'll post some pictures of the Patterns and the castings when I get time.

Later, Wes

I've been lurking here for a couple of weeks. I like this place.

First I'll introduce myself. I'm a full time Machinist and I love it! I have two lathes at home. A 13" X 60" LeBlond and a South Bend Junior 9" X 48". I have a Enco bench mill and a couple of welders. Ive also been building up a home foundry. The place I work just bought an older CNC mill. They have been sending me to school to learn how to run it. I've built several engines, steam and atmospheric. I've been wanting a Tesla style turbine. I love the way they sound:O).

My next project will be some patterns that I've drawn up to build my own Tesla Turbine. I plan on using CD's for the discs and bearings from small RC cars for the shaft. I'm planing on building the patterns on the CNC mill at school. I'll post some pictures of the Patterns and the castings when I get time.

Later, Wes