- Joined

- Jun 12, 2012

- Messages

- 88

- Reaction score

- 68

I fell in love with the Gunnarson V4 wobbler during a recent post-op hospital stay. Drawings of engines are great things to lose yourself in while in a medicated haze, and fantasizing about a brass-and-bronze-and-steel beauty like this, mentally manufacturing and assembling all the parts, makes even hospital food endurable.

Now I'm back on my feet (more or less) I'm trying to make this thing a reality as my second build, and my first set of WIP postings. Please forgive me if there are too many pictures, or too much of anything (or not enough something, like substance!), and advise me accordingly.

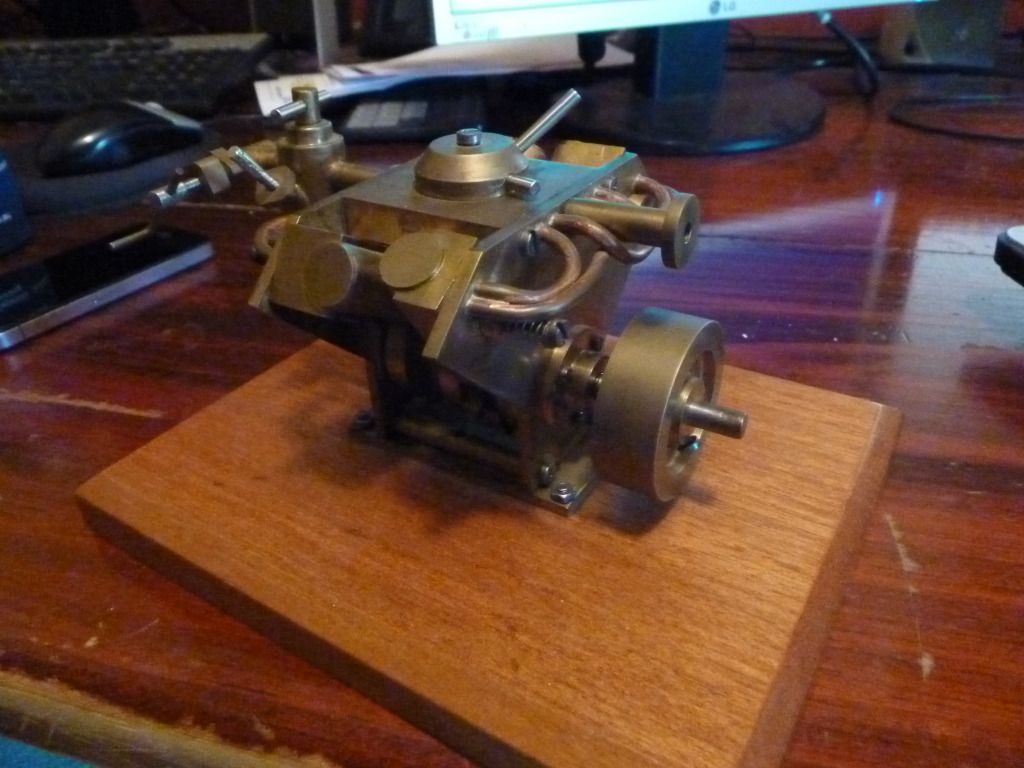

Here's a pic of the Story So Far: basically the "frame" of the engine: Endplates, Spacers, Reversing Valve Block and Exhaust Flange:

The original design of this engine (which I discovered in "Steam and Stirling Engines You Can Build, Vol.I) is in metric. Neither I nor my machines speak metric, so I took a tip from elsewhere in the same book and I'm substituting 1/16" for millimeters -- a nice and easy "conversion," with the added advantage that it increases the size of the project by 60%. Since this is destined to be nothing but a stationary engine this is fine...also, it makes it harder for me to lose the parts. All the parts thus far are 360 brass, which is a dream to machine. Here they are, with a few brief notes:

The Endplates were made of two pieces of 3/16" brass plate, riveted together so they could be drilled and cut at the same time.The endplates were made of two pieces of 3/16" brass plate, riveted together so they could be drilled and cut at the same time. Then two edges were milled square, and used as the X-Y baselines for all subsequent markings.

Here they are still bound together, spray-painted with black primer on one side, marked out, drilled, and rough-cut...

....then, here, milled and finished down to the mark-out lines and separated. After this they were filed and finished, the primer removed with alcohol, and all sides cleaned up with a pad sander. To give an idea of scale these parts are photographed on 1/4" graph paper.

Next up: two identically-sized Spacers...1/2" diameter brass turned, drilled and tapped each end. (Don't they look grand in close-up? Like celestial organ pipes, all straight and round and golden).

Now then, here's where it starts getting interesting. The Reversing Valve Block, which complements the spacers by establishing the length of the engine at the top of the "V", and accommodates the routing of the steam by internal passages. The Reversing Valve will eventually sit on top of it, the manipulation of which will re-route the steam's passage through the Block, thus causing the engine to run either forward or backward. I'm also hoping it might provide at least a rudimentary speed control. Certainly, it presents a nicely toothy and potentially satisfying machining challenge to a relative newbie. Here's how mine began, as a raw chunk of brass. (I know, they all do, but I'm still childishly fascinated by this process).

The chunk was set up in a vise in the mill, milled square, and the intake and exhaust ports drilled and tapped.

The remaining holes to be drilled in the ends of the Valve Block...steam ports and mounting screws...were matched with those in the endplates. To temporarily assemble them together the Exhaust Flange was made now, turned and threaded (and, eventually, knurled) from 1" brass.

Using the Exhaust Flange as a locating bolt the Endplates were used as drilling templates for each end of the Valve Blocks, in turn. A nice beefy angle block kept everything nice and square.

All necessary holes drilled, the steam chambers joining the steam ports could be milled with a two-flute cutter.

Time now for clean-up...a great opportunity to finally use my four-insert surface milling attachment. I'd bought this when I bought my mill, sure I'd use it constantly, and it's been lying in state in the cabinet ever since. But, boy, does it provide a nice finish! Well worth the wait. The eagle-eyed among you (just about everyone, near as I can tell) will notice the damage-control in the middle -- I'd drilled and tapped w-a-a-y oversize the pivot point for the Reversing Valve, and so screwed and soldered a plug in place, then re-drilled it after finishing the surface.

See what I mean?

Anyway, that's the finished Block, and the end of the story for the parts so far, bringing us to the assembly pictured at the top of this posting. Next are the Bottom Plate, Crankshaft Bearings, and Reversing Valve, I guess. Then it'll be onward to the Crankshaft, which gives me a headache to even think about.

xjs

Now I'm back on my feet (more or less) I'm trying to make this thing a reality as my second build, and my first set of WIP postings. Please forgive me if there are too many pictures, or too much of anything (or not enough something, like substance!), and advise me accordingly.

Here's a pic of the Story So Far: basically the "frame" of the engine: Endplates, Spacers, Reversing Valve Block and Exhaust Flange:

The original design of this engine (which I discovered in "Steam and Stirling Engines You Can Build, Vol.I) is in metric. Neither I nor my machines speak metric, so I took a tip from elsewhere in the same book and I'm substituting 1/16" for millimeters -- a nice and easy "conversion," with the added advantage that it increases the size of the project by 60%. Since this is destined to be nothing but a stationary engine this is fine...also, it makes it harder for me to lose the parts. All the parts thus far are 360 brass, which is a dream to machine. Here they are, with a few brief notes:

The Endplates were made of two pieces of 3/16" brass plate, riveted together so they could be drilled and cut at the same time.The endplates were made of two pieces of 3/16" brass plate, riveted together so they could be drilled and cut at the same time. Then two edges were milled square, and used as the X-Y baselines for all subsequent markings.

Here they are still bound together, spray-painted with black primer on one side, marked out, drilled, and rough-cut...

....then, here, milled and finished down to the mark-out lines and separated. After this they were filed and finished, the primer removed with alcohol, and all sides cleaned up with a pad sander. To give an idea of scale these parts are photographed on 1/4" graph paper.

Next up: two identically-sized Spacers...1/2" diameter brass turned, drilled and tapped each end. (Don't they look grand in close-up? Like celestial organ pipes, all straight and round and golden).

Now then, here's where it starts getting interesting. The Reversing Valve Block, which complements the spacers by establishing the length of the engine at the top of the "V", and accommodates the routing of the steam by internal passages. The Reversing Valve will eventually sit on top of it, the manipulation of which will re-route the steam's passage through the Block, thus causing the engine to run either forward or backward. I'm also hoping it might provide at least a rudimentary speed control. Certainly, it presents a nicely toothy and potentially satisfying machining challenge to a relative newbie. Here's how mine began, as a raw chunk of brass. (I know, they all do, but I'm still childishly fascinated by this process).

The chunk was set up in a vise in the mill, milled square, and the intake and exhaust ports drilled and tapped.

The remaining holes to be drilled in the ends of the Valve Block...steam ports and mounting screws...were matched with those in the endplates. To temporarily assemble them together the Exhaust Flange was made now, turned and threaded (and, eventually, knurled) from 1" brass.

Using the Exhaust Flange as a locating bolt the Endplates were used as drilling templates for each end of the Valve Blocks, in turn. A nice beefy angle block kept everything nice and square.

All necessary holes drilled, the steam chambers joining the steam ports could be milled with a two-flute cutter.

Time now for clean-up...a great opportunity to finally use my four-insert surface milling attachment. I'd bought this when I bought my mill, sure I'd use it constantly, and it's been lying in state in the cabinet ever since. But, boy, does it provide a nice finish! Well worth the wait. The eagle-eyed among you (just about everyone, near as I can tell) will notice the damage-control in the middle -- I'd drilled and tapped w-a-a-y oversize the pivot point for the Reversing Valve, and so screwed and soldered a plug in place, then re-drilled it after finishing the surface.

See what I mean?

Anyway, that's the finished Block, and the end of the story for the parts so far, bringing us to the assembly pictured at the top of this posting. Next are the Bottom Plate, Crankshaft Bearings, and Reversing Valve, I guess. Then it'll be onward to the Crankshaft, which gives me a headache to even think about.

xjs