mwilkes

Random Dude

- Joined

- Oct 19, 2012

- Messages

- 58

- Reaction score

- 33

Hi folks - new to this forum and building a Stuart 10V (my second engine - first one was a little stuart oscillator - http://markwilkes.blogspot.ie/2012/02/stuart-steam-oscillator-part-iii.html).

My question is this: why do they ask for diagonal steam ports in the cylinder on the plans? Surely it's much simpler to go straight down from the port face, then straight in at right angles from either end of the cylinder?

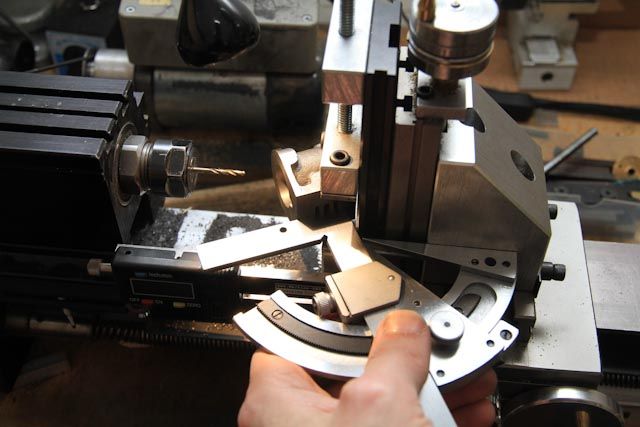

That way you don't have to compensate if you bored the cylinder slightly larger than specified. I had to bore out to 20.5mm because the casting was so badly cored....i'm terrified of drilling at x degrees and missing the steam port :hDe:

thx

My question is this: why do they ask for diagonal steam ports in the cylinder on the plans? Surely it's much simpler to go straight down from the port face, then straight in at right angles from either end of the cylinder?

That way you don't have to compensate if you bored the cylinder slightly larger than specified. I had to bore out to 20.5mm because the casting was so badly cored....i'm terrified of drilling at x degrees and missing the steam port :hDe:

thx