You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Square holes

- Thread starter firebird

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

old-biker-uk

Well-Known Member

- Joined

- Jan 11, 2008

- Messages

- 76

- Reaction score

- 5

Dennis

The hand turning is the easy bit! For the little knurled knobs on the dividers I turn and screw the threaded part and rough out the shape leaving the part to be knurled. (The knurling wheels both spiral & dot were made according to the instructions of Mr Ford here.

After knurling the knobs are parted off, reversed & held by the threaded end in stub mandrels, finished by hand turning.

Hand turning is one of those things you really just have to have a go at. All you need is a few simple tools & a rest.

I have hand turning rests made for each lathe but they dont have to be anything special, a bar in the top slide tool rest is OK.

You learn more about cutting angles by doing some hand turning than from a shed load of workshop manuals !

Mark

The hand turning is the easy bit! For the little knurled knobs on the dividers I turn and screw the threaded part and rough out the shape leaving the part to be knurled. (The knurling wheels both spiral & dot were made according to the instructions of Mr Ford here.

After knurling the knobs are parted off, reversed & held by the threaded end in stub mandrels, finished by hand turning.

Hand turning is one of those things you really just have to have a go at. All you need is a few simple tools & a rest.

I have hand turning rests made for each lathe but they dont have to be anything special, a bar in the top slide tool rest is OK.

You learn more about cutting angles by doing some hand turning than from a shed load of workshop manuals !

Mark

tel

Well-Known Member

- Joined

- Feb 8, 2008

- Messages

- 3,293

- Reaction score

- 44

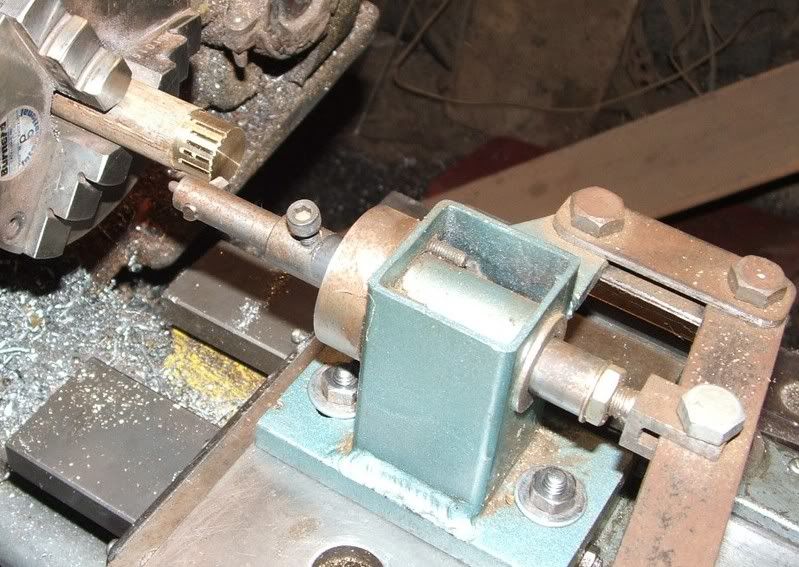

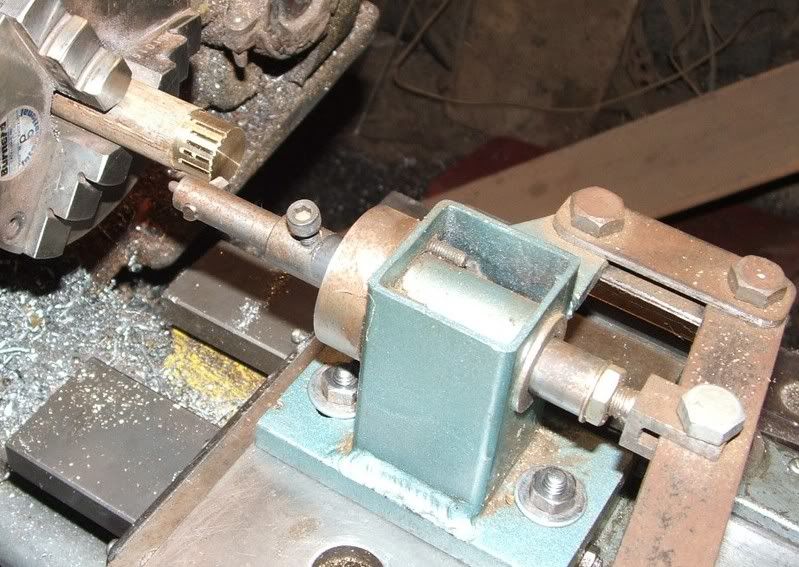

Hmmmm .... seems I lied, mine doesn't mount on the topslide, it bolts direct to the cross slide. Haven't used it for a few years - Mr.Douglas gets most of that sort of work these days

The mounting arrangement allows for some offsetting for tapered work.

The mounting arrangement allows for some offsetting for tapered work.

Tel

That looks a handy tool and something I have considered building for a while. Thanks for the photos it makes the building of one lool very straight-forward.

Circlip

Thanks for the acknowledgement. It was not my intention to "jump down your throat" but I am very pleased you have understood what I meant and have taken it on-board in your reply to Rich

Many thanks

Julian

That looks a handy tool and something I have considered building for a while. Thanks for the photos it makes the building of one lool very straight-forward.

Circlip

Thanks for the acknowledgement. It was not my intention to "jump down your throat" but I am very pleased you have understood what I meant and have taken it on-board in your reply to Rich

Many thanks

Julian

What a brilliant thread ;D .............. Mark :bow: top class stuff mate, if I ever get a little more free time I could well be trying to pick your brain

I think as with most folk on here we would love to have all the available tooling ............ state of the art Rotary Broach etc, but after all, it's a hobby so it ain't going it's unlikely to happen ........ I admit to being a gadget freak but to be fair I'm among stiff competition here

........ I admit to being a gadget freak but to be fair I'm among stiff competition here  ........ so thanks for sharing all the above idea's, they are just great, whether I'll ever make a square punch remains to be seen but, knowing that I can if I want is what matters 8)

........ so thanks for sharing all the above idea's, they are just great, whether I'll ever make a square punch remains to be seen but, knowing that I can if I want is what matters 8)

Cheers Guys

CC

I think as with most folk on here we would love to have all the available tooling ............ state of the art Rotary Broach etc, but after all, it's a hobby so it ain't going it's unlikely to happen

Cheers Guys

CC

The Pictures as promised.

Mine is based on the ME model only it mounts to the AXA style wedge toolpost. 5 seconds its on, and off.

I am going to rebore the ram and make it 1 1/8 instead of 7/8. This one is a bit wimpy for 5/32 keyways and larger. But smaller ones are OK in steel.

SmoggyTurnip

Well-Known Member

- Joined

- Mar 12, 2008

- Messages

- 106

- Reaction score

- 0

old-biker-uk said:The hole was for this centre hole divider.

That is a beautiful center hole divider! ... What's a center hole divider???

B

baldrocker

Guest

Umm ditto

BR

BR

Similar threads

- Replies

- 39

- Views

- 4K

- Replies

- 11

- Views

- 2K

- Replies

- 61

- Views

- 8K