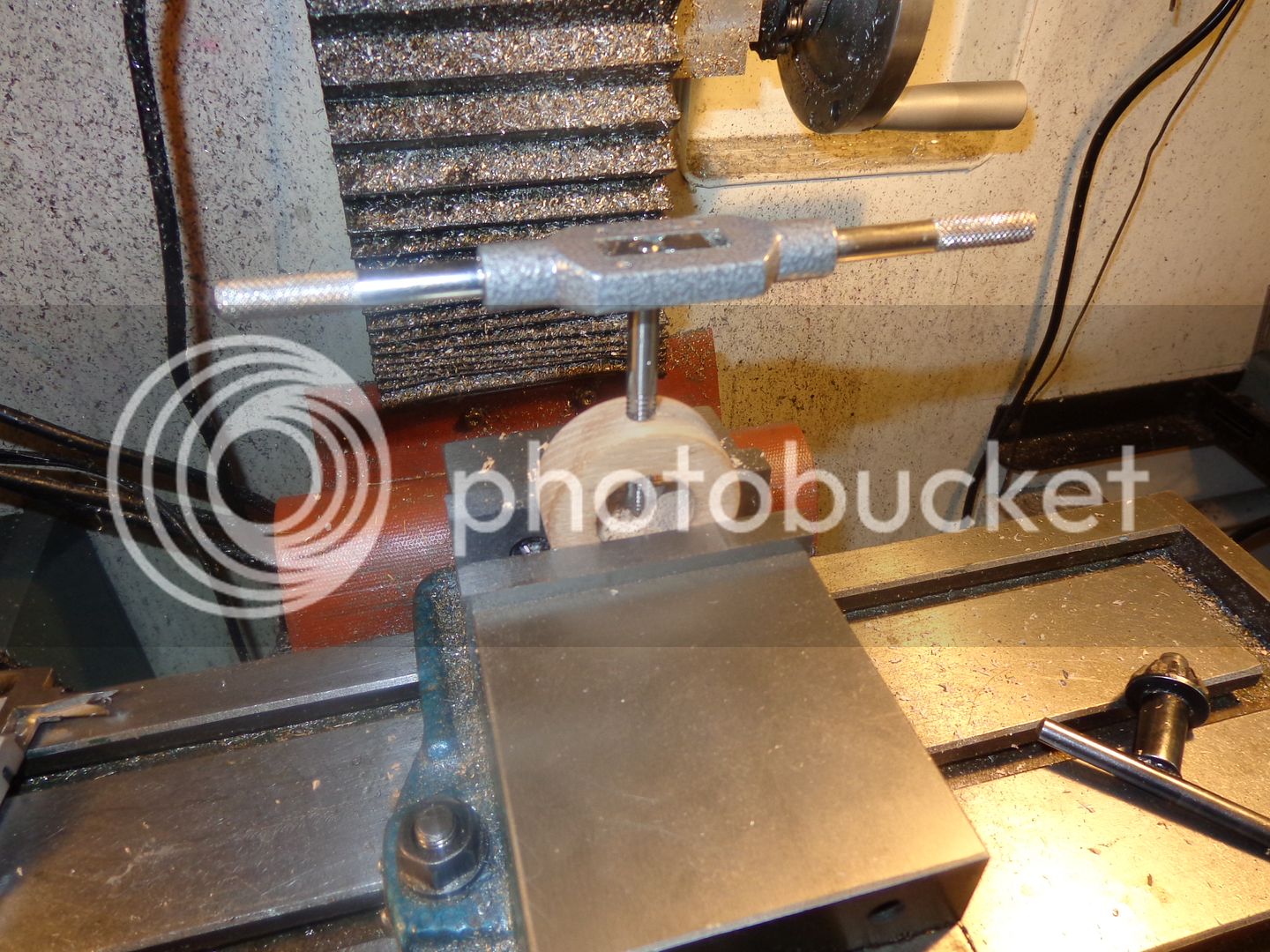

Okay--I have to admit, that up until yesterday, I hadn't heard of a "spark tester". For me, it was good enough to lay the sparkplug out on the engine block to see if I had any spark, or to grit my teeth and hold onto the coil wire, waiting for that incredible ZZZZAP!!! Yesterday I received my first ever CDI ignition package from S&S Machine and Engineering, owned by Roy Sholl. Roy has warned me, both in the instructions and by email, to not let the cdi fire unless you were sure that the high current had a GOOD path to ground, otherwise it could fry the CDI and the Hall effect sensor. I dug around thru all the literature that was on the CD that came with the CDI system, and found a picture of a spark tester. I could have probably ordered one from Roy, but between shipping charges and the time factor involved, I decided to make my own. I don't have any insulating plastic or nylon around my shop, but I do have lots of dry oak hardwood left over from the living room floor, which got new hardwood a few years ago. I started out by using a 2" hole saw to cut a piece out of one of the short boards.