Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

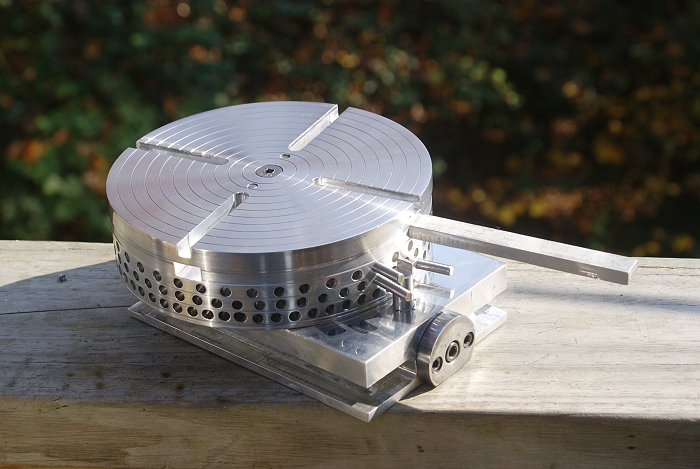

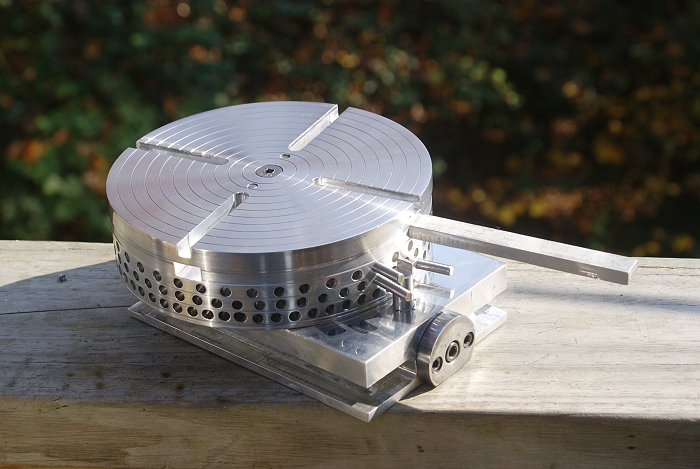

Marv was generous enough to allow me to pirate one of his ideas. I borrowed his small rotary table idea and reworked it a bit to function as I wanted.

The 3 rows of holes, 40, 50 and 60 per row allow for indexing a wide variety of hole combinations. Using this combination one can do patterns of 2,3,4,5 6, 8,10,12,15,20,25,30,40,50 and 60 holes. With a bit on ingenuity, patterns on up to 120 holes are possible. More than enough for the typical model build.

The table indexes against the stop post using 3/16 precision ground dowel pins., It took a bit of hand filing to make the post work with all three rows and still allow for a "squared" table top for set ups. The top is removable, allowing me to use other tops with different functionality. The top plate is indexed by two 3/16 dowel pins so that it is always mounted in the same position. Some of the other tops planned include a small tooling plate, a modified finger plate and a version with interchangeable centering dowels of various sizes for quickly centering pre-drilled parts. A dockable tilting table is also planned.

The semi-circular piece on the end is the table lock/brake which either locks the table in place or allows me to adjust the drag. Since it is a manual table, controlling the drag allows me to do some milling operations without the end mill spinning the table out of control. I left room in the base for future modification, should I decide to make it worm gear driven. Yeah... I know... it's a poor man's tool and hardly a substitute for the real deal, but for now its going to have to do.

Getting to work with larger chunks of material was refreshing. The project proved that the modified 7 inch lathe will work just fine out to a 6 inch diameter. It also added some much needed capability to my mill. Good project and one I've enjoyed completely. This tool just keeps generating ideas and evolving new ways to use it.

Steve

The 3 rows of holes, 40, 50 and 60 per row allow for indexing a wide variety of hole combinations. Using this combination one can do patterns of 2,3,4,5 6, 8,10,12,15,20,25,30,40,50 and 60 holes. With a bit on ingenuity, patterns on up to 120 holes are possible. More than enough for the typical model build.

The table indexes against the stop post using 3/16 precision ground dowel pins., It took a bit of hand filing to make the post work with all three rows and still allow for a "squared" table top for set ups. The top is removable, allowing me to use other tops with different functionality. The top plate is indexed by two 3/16 dowel pins so that it is always mounted in the same position. Some of the other tops planned include a small tooling plate, a modified finger plate and a version with interchangeable centering dowels of various sizes for quickly centering pre-drilled parts. A dockable tilting table is also planned.

The semi-circular piece on the end is the table lock/brake which either locks the table in place or allows me to adjust the drag. Since it is a manual table, controlling the drag allows me to do some milling operations without the end mill spinning the table out of control. I left room in the base for future modification, should I decide to make it worm gear driven. Yeah... I know... it's a poor man's tool and hardly a substitute for the real deal, but for now its going to have to do.

Getting to work with larger chunks of material was refreshing. The project proved that the modified 7 inch lathe will work just fine out to a 6 inch diameter. It also added some much needed capability to my mill. Good project and one I've enjoyed completely. This tool just keeps generating ideas and evolving new ways to use it.

Steve