- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

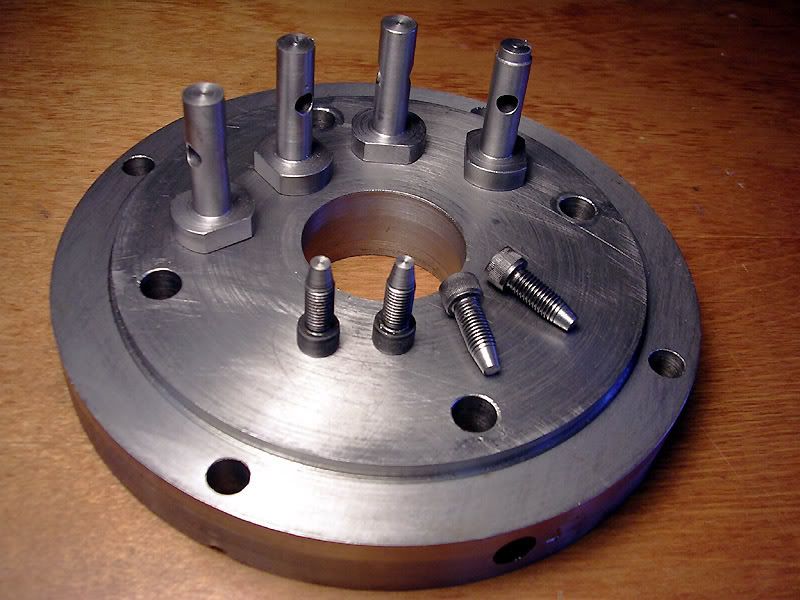

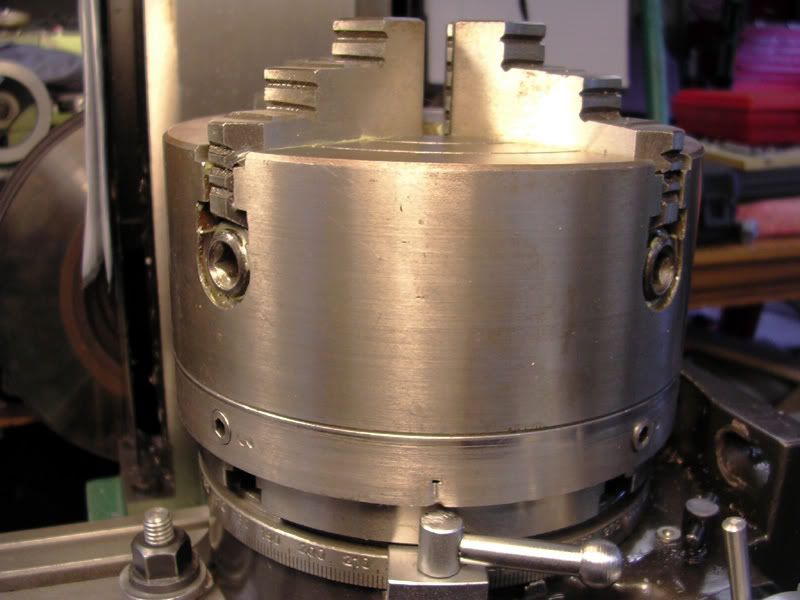

This project was inspired by some pictures posted by MKLOTZ. I had an old, Sears 4 jaw chuck that didn't get much use and a constant need to drill indexed holes in things, so I built this small rotary table to accommodate the chuck.

There are two rows of indexing holes, one contains 20 holes and the other 24. Between the two rows, I can get 2, 3, 4, 5, 6, 8, 10, 12, 20, and 24 evenly spaced holes. The flat detent spring was was formed from a piece of a worn out bandsaw blade which I've been holding onto for years.

The rectangular base fits nicely into my mill/drill vice. I should probably also figure out a way to fasten it to my drill press table... Chuck

There are two rows of indexing holes, one contains 20 holes and the other 24. Between the two rows, I can get 2, 3, 4, 5, 6, 8, 10, 12, 20, and 24 evenly spaced holes. The flat detent spring was was formed from a piece of a worn out bandsaw blade which I've been holding onto for years.

The rectangular base fits nicely into my mill/drill vice. I should probably also figure out a way to fasten it to my drill press table... Chuck