Good explanation Mayhugh. I would add a note: Inadequate coil voltage can confuse, as you may get a nice blue spark across the desired gap "in air at atmospheric pressure" but not "inside the engine in a fuel-air mix at compression pressures". A small puff of "easy-start" can sometimes tell if the spark is happening inside the engine. turned slowly towards compression it should kick when the spark fires. (My Moto Guzzi will do it when I am checking the timing and turning the engine by hand, if there is petrol-air mix in the engine! - The "chuff" always makes me jump!).

K2

Mine is: Model Engineering is the re-engineering of a full-sized "something" - to a smaller (or sometimes larger!) size in order to demonstrate particular features of the original Engineering.

E.g. even a cardboard cut-out viaduct on a double-O gauge railway, that carries a small train across a modelled valley is Model Engineering. But a stick of wood that carries the train, with a cut-out picture in front, doesn't count! ( I have seen both!). It doesn't have to be "shiny-bright metal whirring bits".

K2

K2

Fair comment, but each to his own philosophy....Hi Steve,

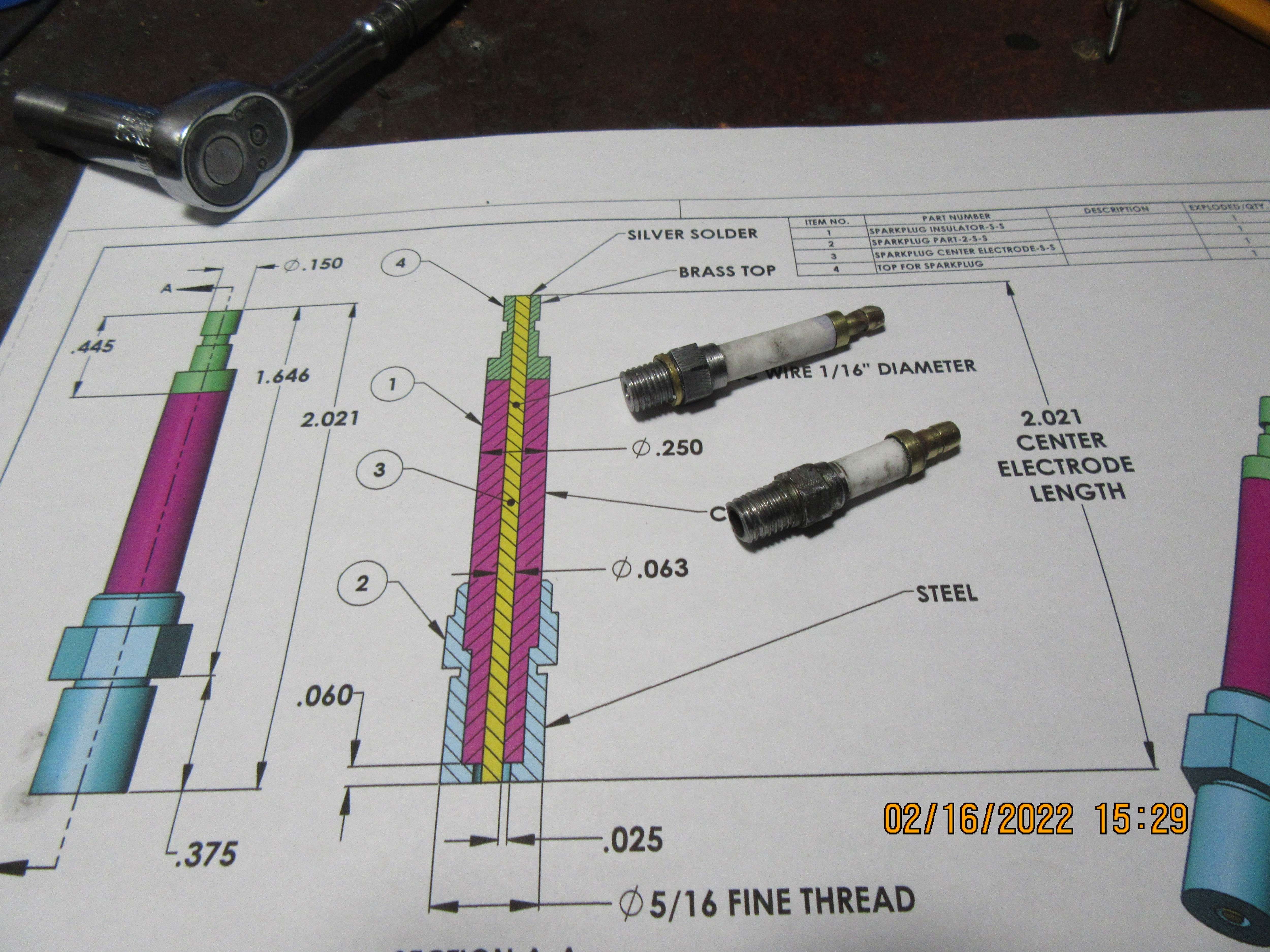

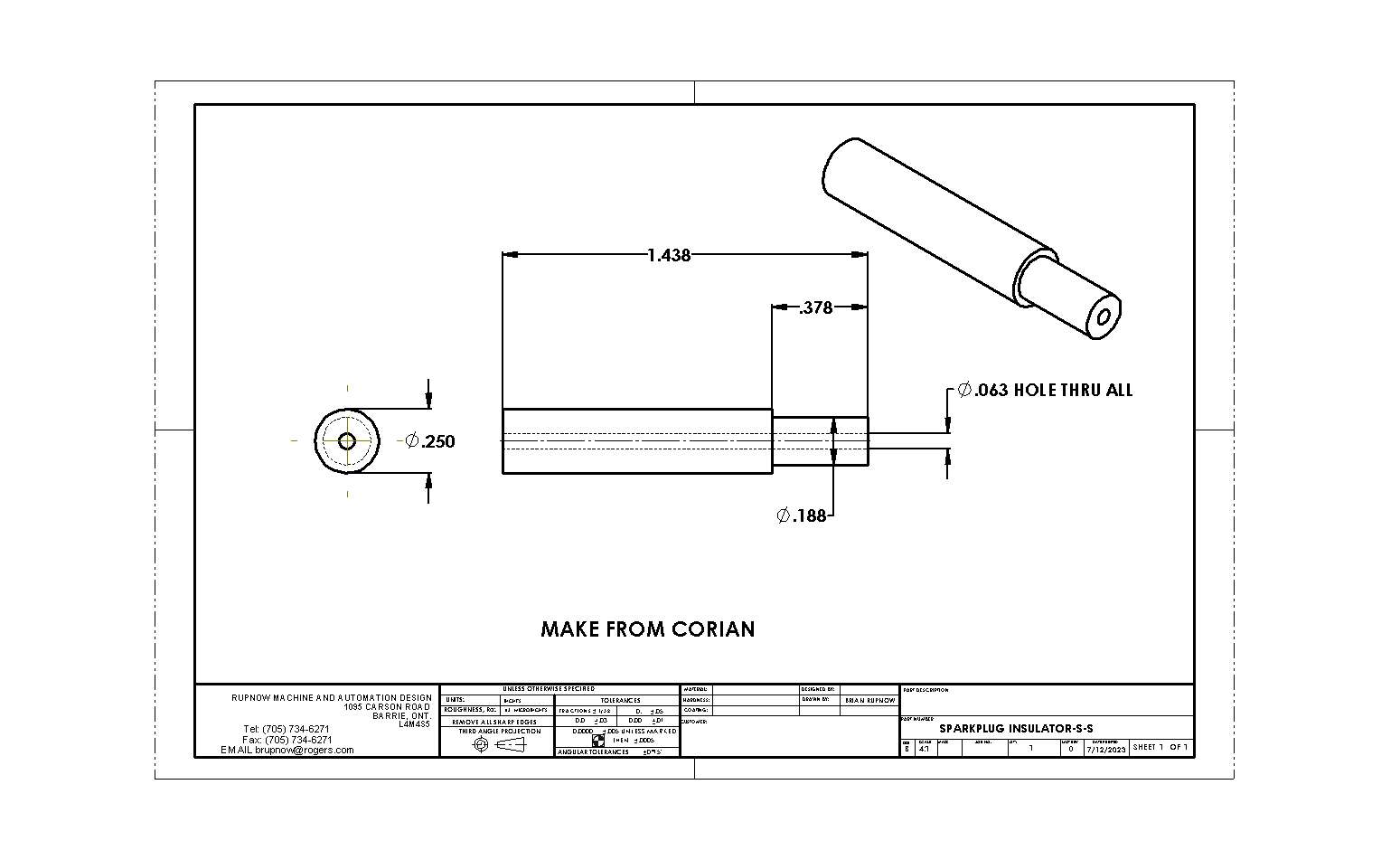

Model engineering is all about making stuff. Some guys make the tooling to make the stuff making spark plug is a synch. With the materials at hand takes me around an hour. johwen

Mine is: Model Engineering is the re-engineering of a full-sized "something" - to a smaller (or sometimes larger!) size in order to demonstrate particular features of the original Engineering.

E.g. even a cardboard cut-out viaduct on a double-O gauge railway, that carries a small train across a modelled valley is Model Engineering. But a stick of wood that carries the train, with a cut-out picture in front, doesn't count! ( I have seen both!). It doesn't have to be "shiny-bright metal whirring bits".

K2