well, I'm here again, after much time, with some new pieces of the scuderi engine

they are the results of several weeks (or months!?) of work

I don't know why, but I'm more slow now then when I was a newbee (ok, I'm still a newbe, with more practise

)

perhaps I now look for a better result and I do prefer to discard a piece that doesn't fit well instead to try to correct/fix it

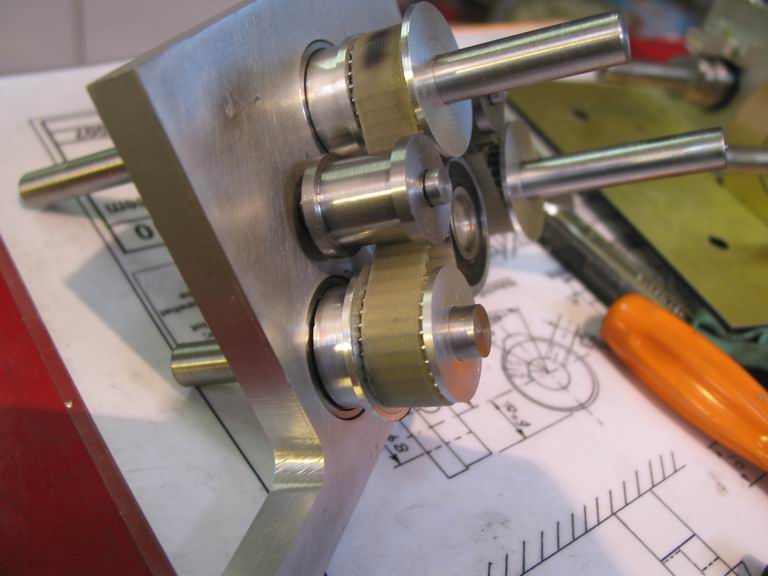

there are 3 tooth belt cog wheels that synchronize, by the mean of the tooth belt, distribution, ignition and the movement of the 2 pistons

I bought a ruled rod of aluminum and bilt the 3 cog wheels

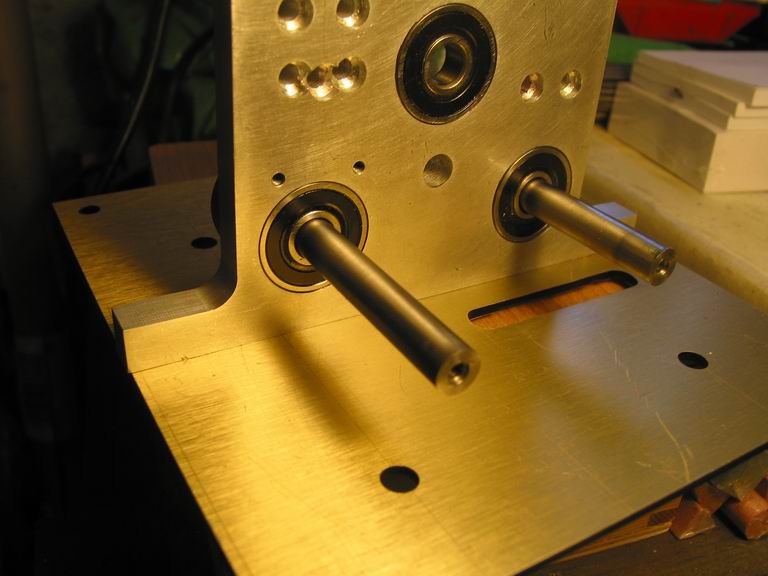

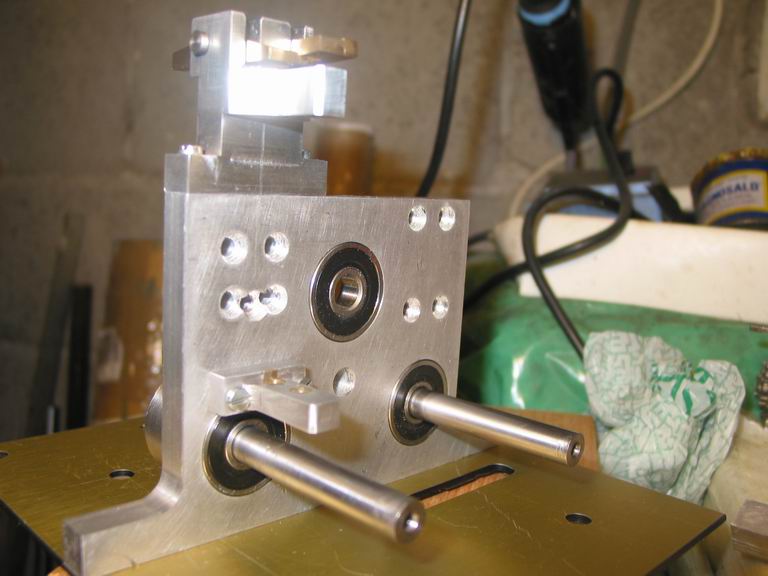

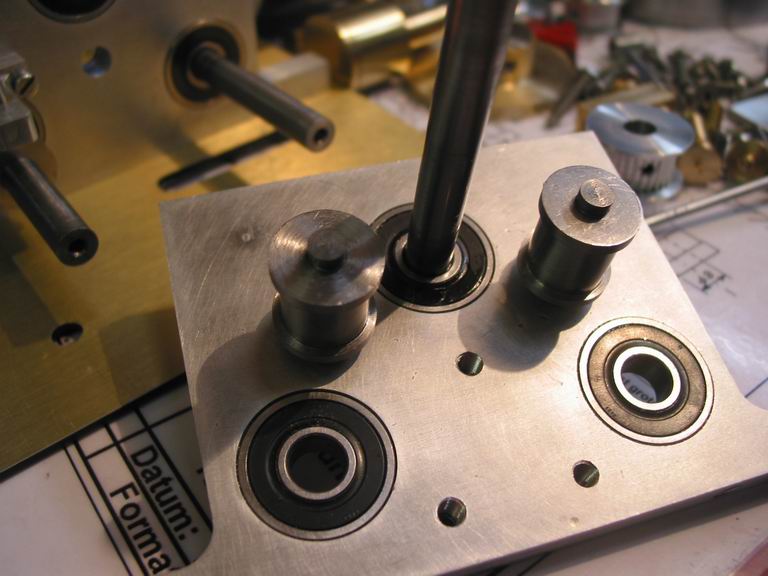

here there are the 2 plates with the roller bearings in seat

with the shafts

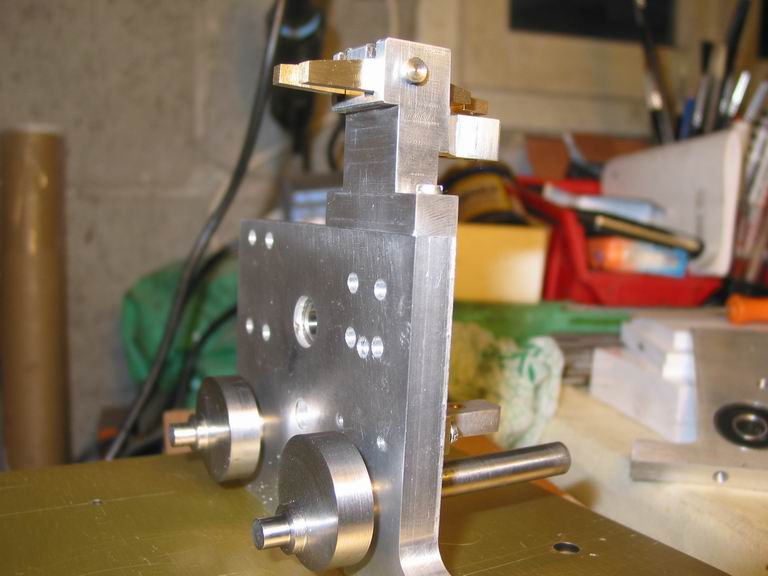

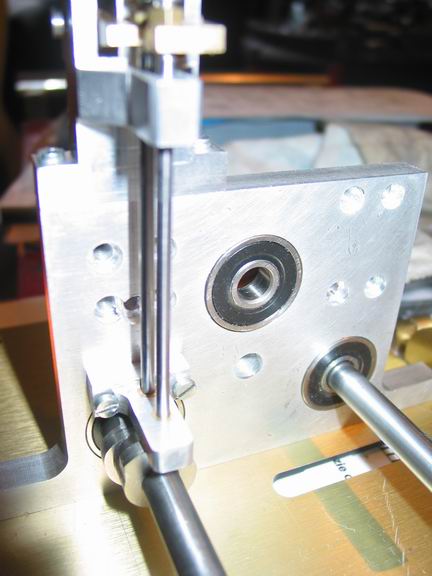

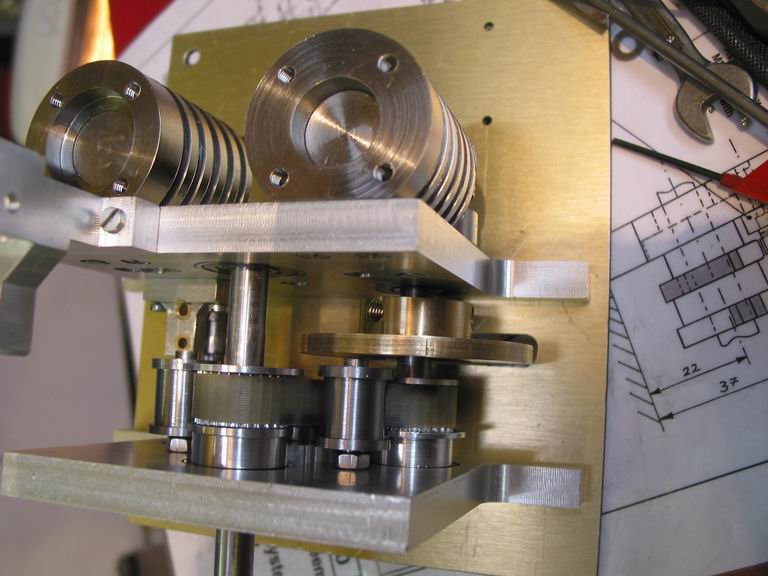

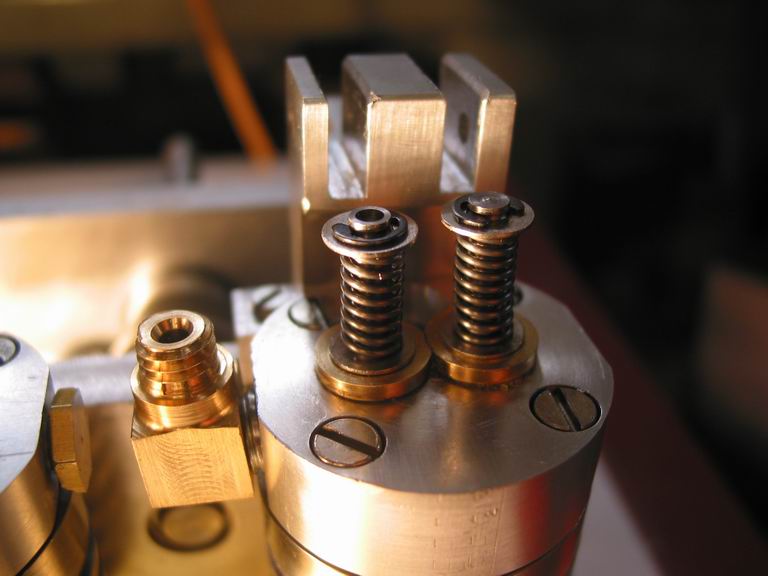

and with part of the distribution system: the guiding block for the pushing rods and for the rockers that push the intake and exhaust valves (sorry for the poor pics)

on the opposite plate the situation is more complex

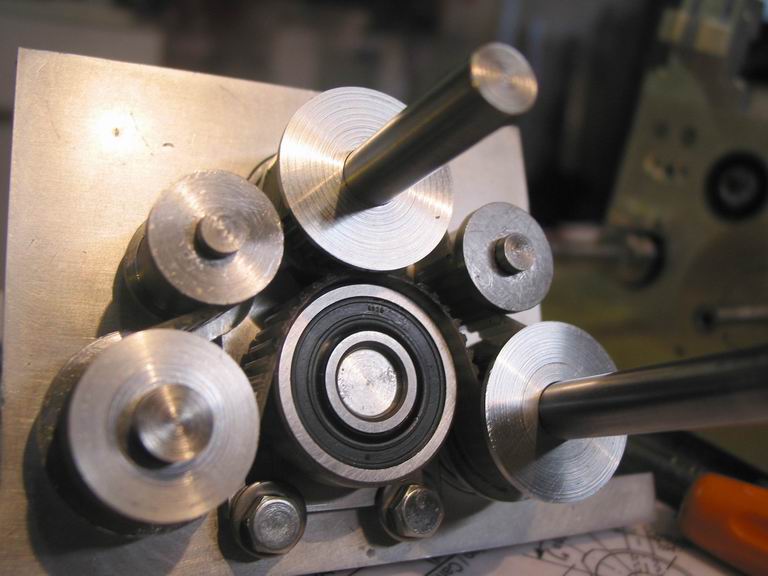

there are many tensioning wheels for the tooth belt: these 2 first

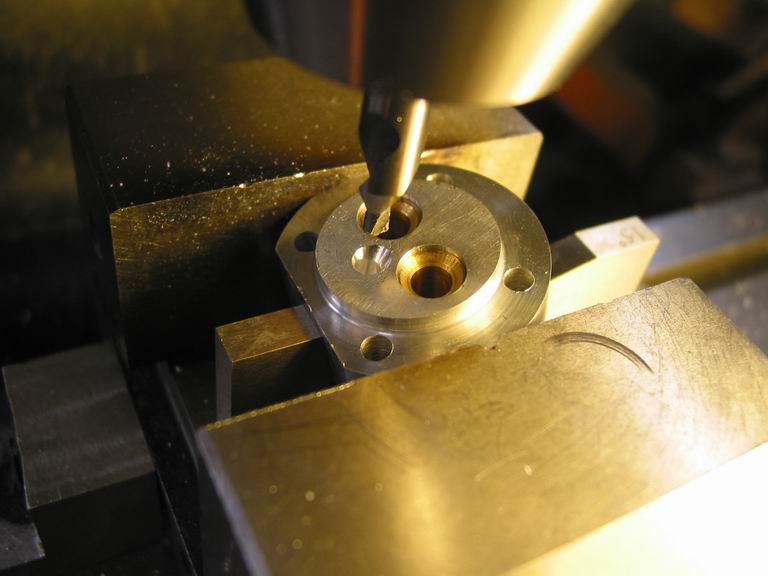

and another that originally was this one

but I discovered that the ruled rod that I had bought was too small in diameter, and the tooth belt remained loosened. so that tensioning wheel must be replaced.

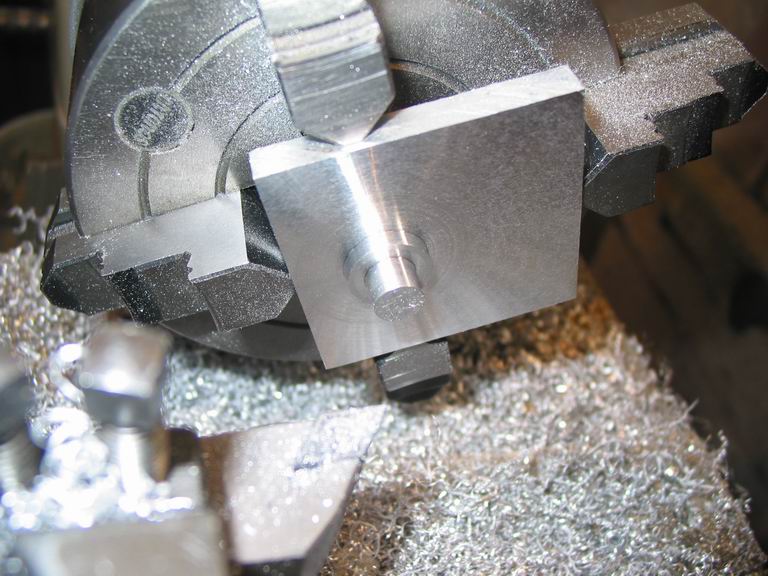

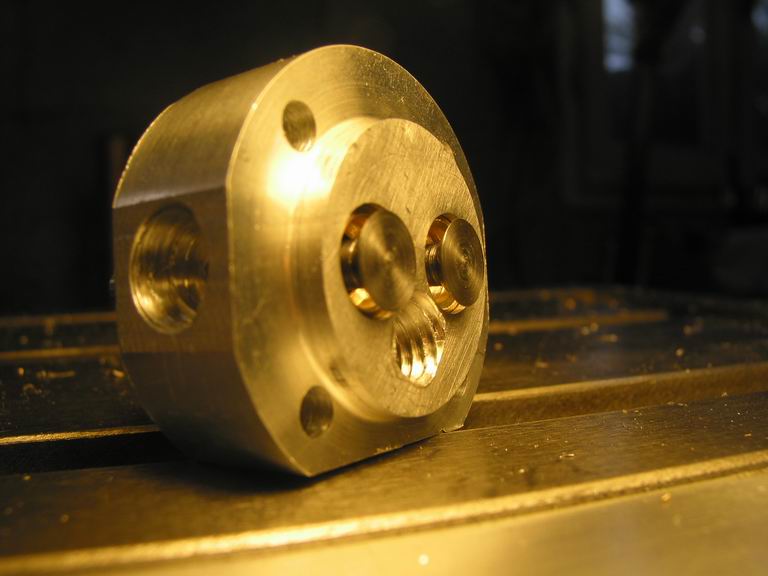

this time I decided to make it in a single piece of aluminum

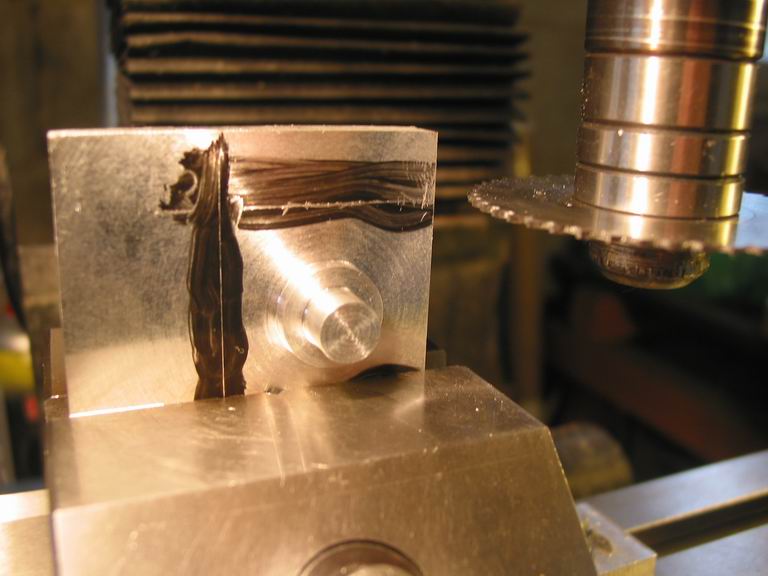

but the belt was loosened again and after several mods (aesthetically not very satisfactory) the problem was solved in this way

here the belt is mounted for a test with provisional shafts

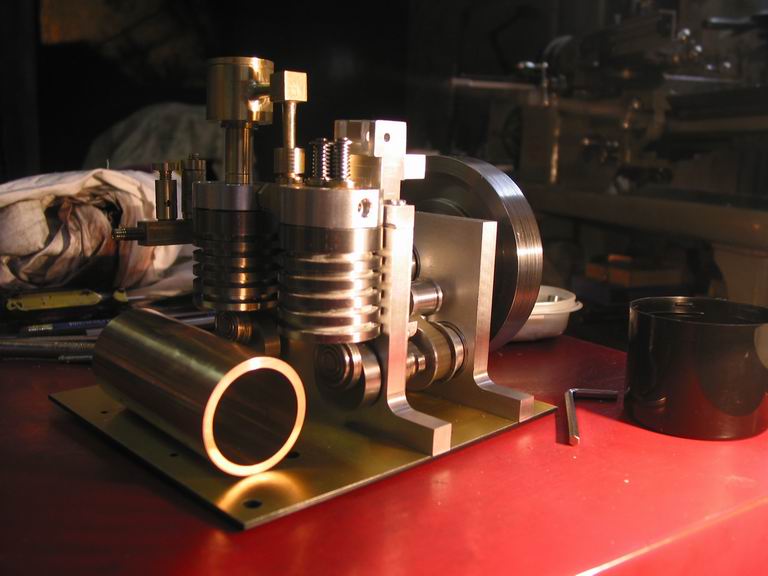

while here the 2 plates are mounted on the base with their own shafts and the tooth belt is properly tensioned: everything seems to turn well and without any effort

the great disk of brass on the lower right is the cam disk for ignition

now I can return to work on the outside

to complete the fuel system, the vapour carb and several other parts that have to be made

and I have to conceive a way to give the ignition at the spark plug, and to build the spark plug too...

I guess that I'm still far to the end of this build ;D