hello!

well, I'm not sure that this is the right section to post, because I'm not one that takes photos and documents every step of the building

there are here some fellows that are very good in this: it come to mind Maryak, but many others take the photocam in the shop for every occurrence

however, at times I'll post my progresses, but (moderator) feel free to move the thread

after 2 steam engine I wanted to try an IC engine, and after a bit of searching I chose the Scuderi engine

I found it on the Jan Ridders web site http://heetgasmodelbouw.ridders.nu/index.htm

it is also on a web site of 'strange' engines, but I can't remember the address

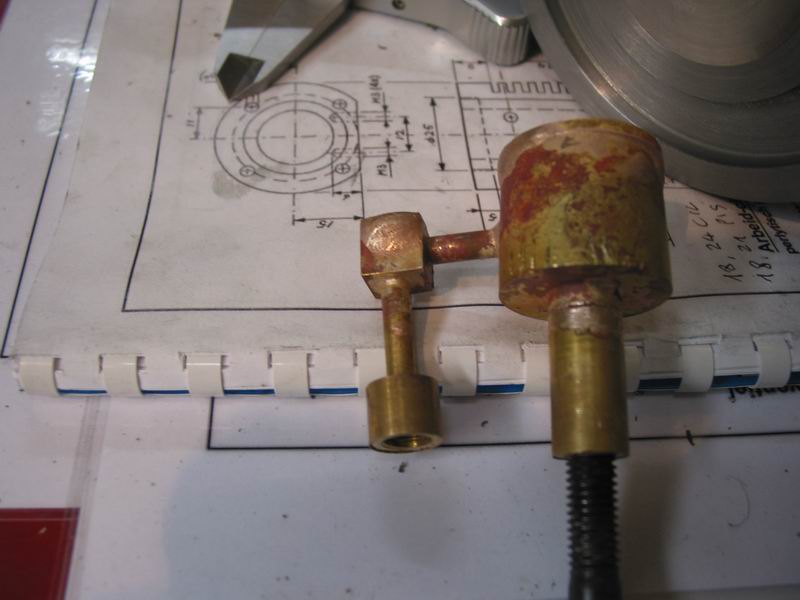

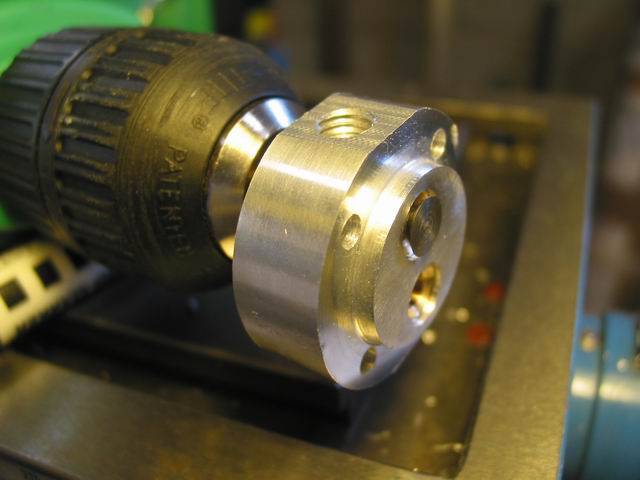

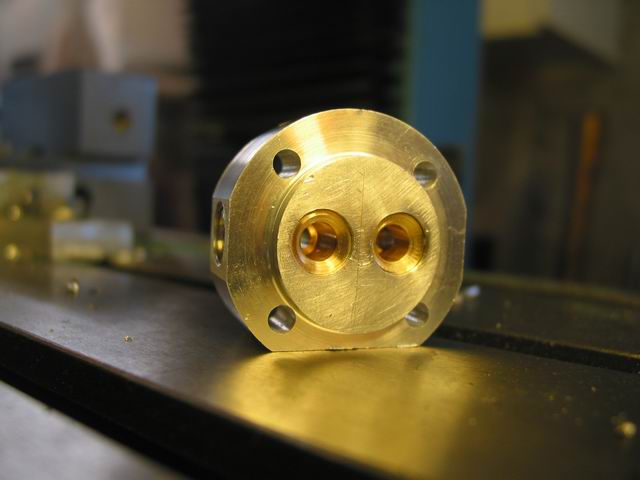

the scuderi engine is a four stroke engine with 2 cylinders, one to compress the air/fuel (without valves, it has a ball with a spring to control the flow) and the second that is a normal 4 stroke cylinder, with 2 valves and a spark plug.

to me it seems a sort of a supercharged engine, but nobody refer to it in this way

Jan Ridder is a good fellow, he send the plans to everyone on request, for free

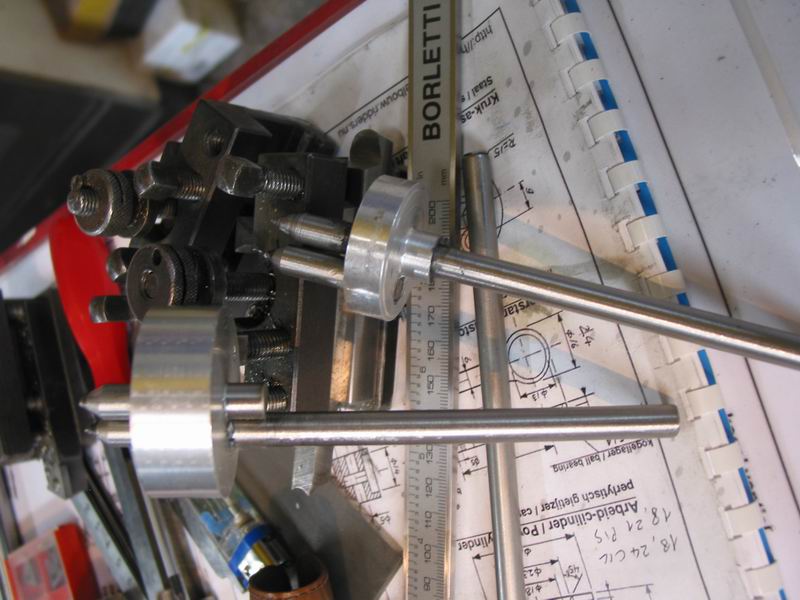

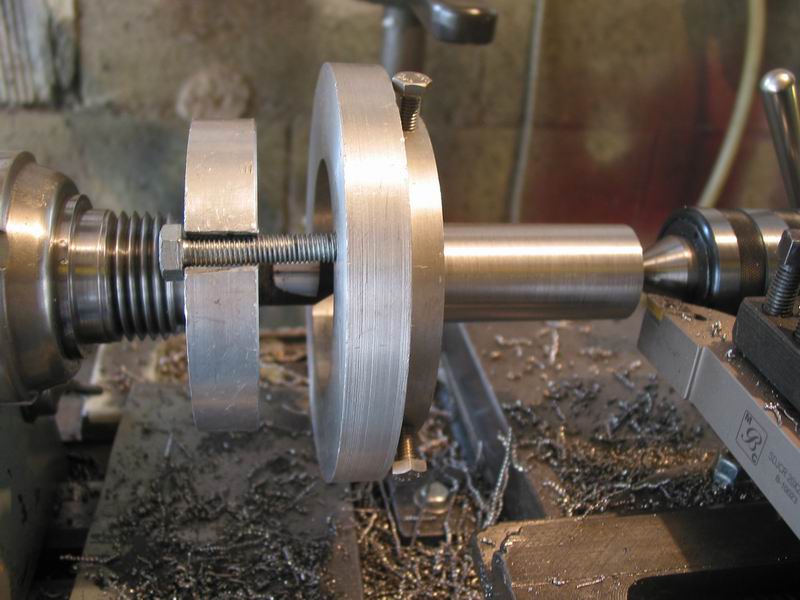

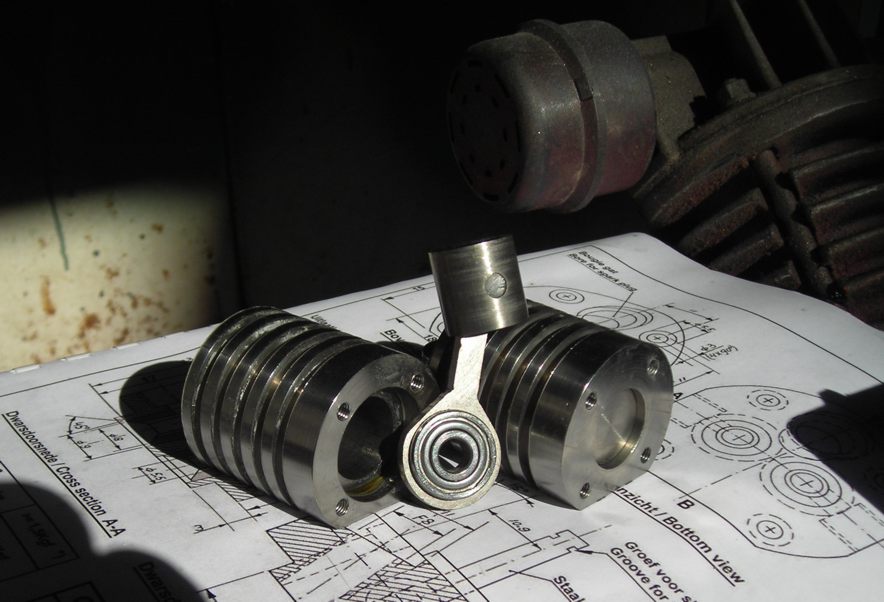

I started the built a couple of weeks ago, and here there are the pics of the 2 cylinders with heads and pistons

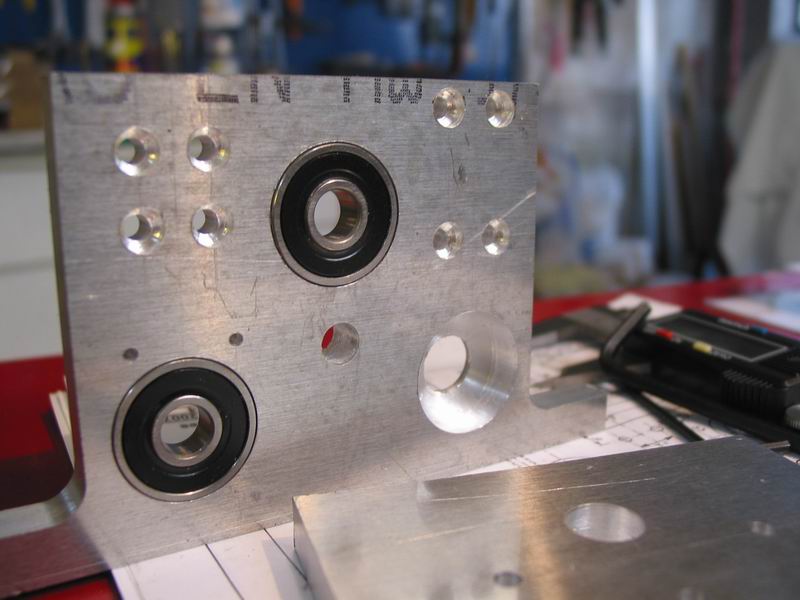

I have a lot of small ball bearings and so I went with 2 of these instead to buy 2 new ball bearings of the correct size: mine are a bit greater in thickness and protrude a bit. I'll fix this later

and as always I can't find cast iron to build the cylinders and pistons: can you guess what I used instead?

oh yes, titanium ;D I fear that I'll have to fix (read re-make) also these pieces, I don't know how titanium will react to the heat of the power cylinder

well, I'm not sure that this is the right section to post, because I'm not one that takes photos and documents every step of the building

there are here some fellows that are very good in this: it come to mind Maryak, but many others take the photocam in the shop for every occurrence

however, at times I'll post my progresses, but (moderator) feel free to move the thread

after 2 steam engine I wanted to try an IC engine, and after a bit of searching I chose the Scuderi engine

I found it on the Jan Ridders web site http://heetgasmodelbouw.ridders.nu/index.htm

it is also on a web site of 'strange' engines, but I can't remember the address

the scuderi engine is a four stroke engine with 2 cylinders, one to compress the air/fuel (without valves, it has a ball with a spring to control the flow) and the second that is a normal 4 stroke cylinder, with 2 valves and a spark plug.

to me it seems a sort of a supercharged engine, but nobody refer to it in this way

Jan Ridder is a good fellow, he send the plans to everyone on request, for free

I started the built a couple of weeks ago, and here there are the pics of the 2 cylinders with heads and pistons

I have a lot of small ball bearings and so I went with 2 of these instead to buy 2 new ball bearings of the correct size: mine are a bit greater in thickness and protrude a bit. I'll fix this later

and as always I can't find cast iron to build the cylinders and pistons: can you guess what I used instead?

oh yes, titanium ;D I fear that I'll have to fix (read re-make) also these pieces, I don't know how titanium will react to the heat of the power cylinder