Hmmmm... just saw on the nightly news that the local authorities had spotted an unruly torch lit mob in this general vicinity. Naaaa..... couldn't be related to this thread.

Ok.... you asked for it, but the first one mentioning the red grease gets it right between the eyes with a frozen halibut. I didn't get long to do any degreasing tonight... but there is one very nice looking Christmas tree in the other room...(grin)

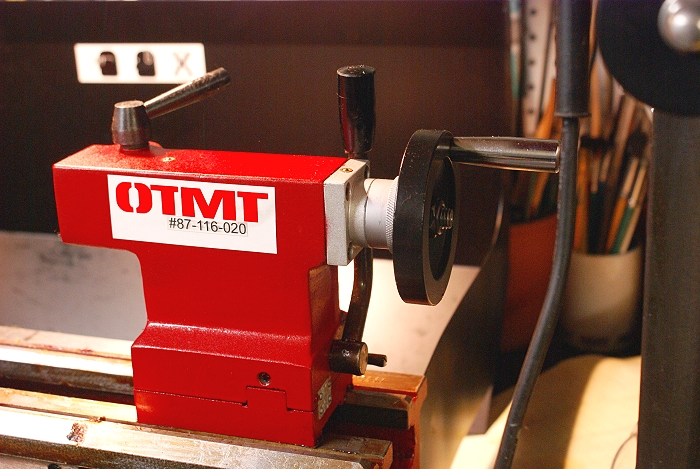

The first glance at the C4 says "mini lathe". Then the second look says "wait a minute... small.... but not mini" By the 3rd look, you've begun to see some nice looking differences. It's 250 pounds of solid bench top iron.

The headstock is much larger than the C2 and the electronics are quite a bit more complex. All the controls are touch pad and have a nice feel, very much like the X3 mill. It came with a 4 inch 3 jaw chuck which will soon be replaced with a 5 or 6 inch version. 100 rpm is the lowest speed but the 1000 watt motor is up to delivering full torque through out the spectrum, topping out at 2000 rpm (and that's moving my friend). No back gear, but the electronics package compensates to keep low speed torque at constant usable levels.

The saddle is MASSIVE for a small mill like this. It has cross feed, normal lead screw feed and a low speed lead screw feed option. one negative.... cross feed is dictated by the direction the Chuck is turning. This will soon be addressed by making the lead screw power feed independent from the spindle drive train. For now, the instant spindle reversing feature will keep me out of trouble.

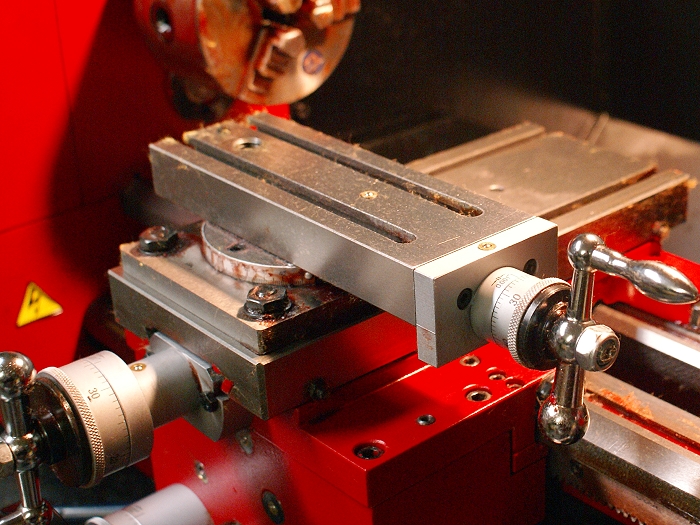

The cross slide and compound both have T slots, so I'm going to have fun finding a whole new bunch of tricks and configurations to use. The compound is mounted with 4 bolts, addressing the well known weak point of the 9x20 lathes. Plenty of oil ports are evident and split nuts on the lead screws make for easy back lash removal. I'll be experimenting to determine just how large of a piece of metal the tools can reach, but it already appears to dwarf the stock C2 in cross slide travel. And yes... it appears that the same extended travel cross slide mod used on many C2 lathes can be adapted to this one as well.

The tail stock taper comes in MT2 and the unit is stock with a clamping leaver which makes a very positive lock with very little pressure required. It has its own "prism" style bed way. The bed has dual prisms, one for the saddle and one for the tailstock

Overall first impressions.... Sieg took time to think things through pretty well before they went to production with the C4. The actions are silky smooth with no noticeable lash. The mass of the machine gives it a different, more capable feel. I've made only 4 or 5 cuts so far, but the difference in feel of the C2 and C4 is immediately notable. Fit and finish is (so far) comparable to the Sx3 mill I recently purchased. This one once again takes Seig a positive step away from the "kit" machines we all know them so well for.

More to come as I get things sorted out and cleaned up a bit more.

Steve