I've been in dialogue with MyHobbyStore about the drawing for £5.95 and postage to NZ is £6.98 and their attempt to justify it. Apparently I was offered a discount on the postage but the email never arrived. In the meantime I realized it was only one sheet and there is a fuzzy copy of the drawing on the MHS link .

(Direct link to MyHobbyStore web page)

Along with the words in the book it was enough to get going, so I set to.

In my spare parts draw I had another lubricator of the LBSC type that is already fitted to the loco. It would give me the container and ratchet mechanism to the right size so it would be form and fit to the original. All I needed to do was replace the insides

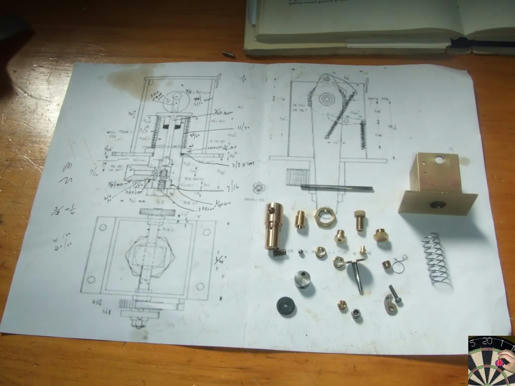

All the new parts with the existing container.

I had to modify some of the dimensions to get it to fit the container, but as I didn't have some of them anyway and had to derive them by scaling from the fuzzy drawing. I was remarkably close as found out when I subsequently sourced the Rob Roy and William book, which has the missing drawing included. (Thanks Chris).

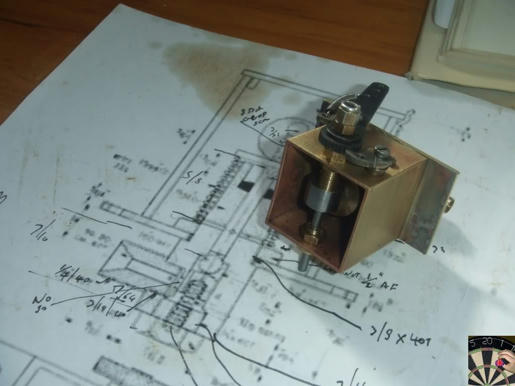

All assembled

Alongside the existing.

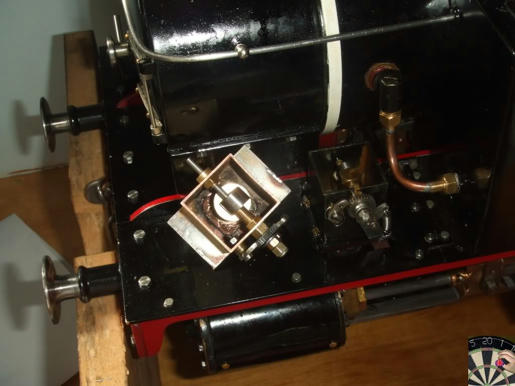

You can see how messy the loco is as a result of the amount of oil the existing lubricator has been pumping out

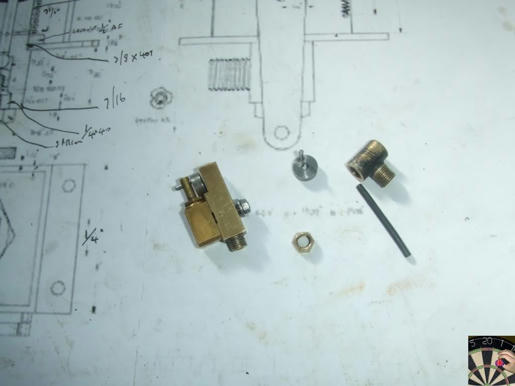

Left over parts from the original LBSC type.

I've tested it by hand with dish washing liquid, it was the nearest to oil without the mess and easy to clean up under the tap. It worked ok emitting a drip or so every few strokes of the piston. It remains to be seen what happens when it is pumping oil against steam pressure.

Now it is all stripped down and the mounting flanges drilled and tapped ready for mounting on the running board. I've just given it a blast in the sand blaster and a coat of etch primer, so that's it for the day.

Pete