You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rob Roy

- Thread starter doubletop

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

While I've been away things have progressed a bit. Actually they've progressed a lot.

You'll recall I had an problem with getting anything above 25psi on gas. So was going to drop the idea. I went to the club at the beginning of the month to show the guys where I had got to and commented on the gas issue. A couple of days later Gavin called me and gave me the name of somebody who, with others has successfully been running locos on propane. One of them a Rob Roy and even a 5" gauge.

Anyway Dave invited me round to his place on the weekend and we spent about 4 hours working through things. I left with a list of jobs.

It's the deflector that's the key to success. This is from these guys experience and years of running successfully. The problem with running on gas is the blower draws the flame down the fire tubes and eventually off the burner head and the flame goes out. They'd also realized that as this draw off of the flame occurs little heat reaches the back-head end of the firebox. Dave also lent me a propane bottle, valves, pressure guages etc to get me going. Great!!

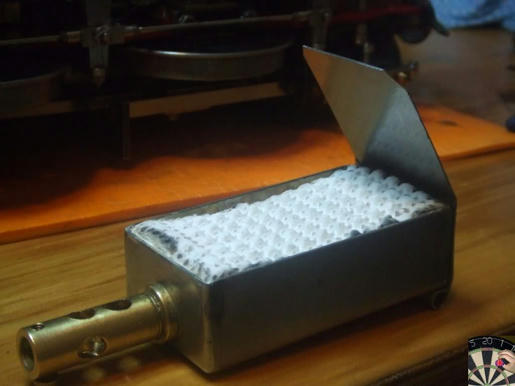

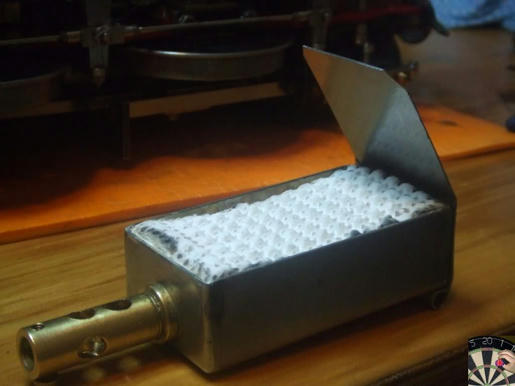

Deflector on the fire tube end of the burner

Deflector fitted in the firebox

Burner installed, also with shield around the primary air inlet (maybe this isn't necessary)

Gas pipe work installed

So this is the first time I'd run it on steam, and of course gas fired.

[ame]http://www.youtube.com/watch?v=-_tMDODla1g[/ame]

Now its freed up it will run on 5 psi and is even quieter now its been run on steam.

Over this past weekend I made a blower out of a computer fan, a plastic funnel and length of 22mm copper pipe

I thought long pipe to keep the temp from the fan (OK how long is that going to last?) . It does the job very well and I've got loads of these cheap fans from dead computers. I can now go from a cold fill, fire up the burner and be at 80psi in 10 mins. I did it again tonight just to confirm it wasn't fluke. I tried to get a video but it didn't come out that well.

Next job is the accumulation test at the club and running on the track.

Pete

You'll recall I had an problem with getting anything above 25psi on gas. So was going to drop the idea. I went to the club at the beginning of the month to show the guys where I had got to and commented on the gas issue. A couple of days later Gavin called me and gave me the name of somebody who, with others has successfully been running locos on propane. One of them a Rob Roy and even a 5" gauge.

Anyway Dave invited me round to his place on the weekend and we spent about 4 hours working through things. I left with a list of jobs.

- Run it on air for an extended period with plenty of oil to free it up.

- Replace the balls in the safety valves with stainless (don't use bike ball bearings they rust up and your safety valves quickly become un-safety valves)

- Mount a gas connection on the rear buffer bar

- Fix the hand pump

- Make an electric blower

- Add a gas deflector on the burner

It's the deflector that's the key to success. This is from these guys experience and years of running successfully. The problem with running on gas is the blower draws the flame down the fire tubes and eventually off the burner head and the flame goes out. They'd also realized that as this draw off of the flame occurs little heat reaches the back-head end of the firebox. Dave also lent me a propane bottle, valves, pressure guages etc to get me going. Great!!

Deflector on the fire tube end of the burner

Deflector fitted in the firebox

Burner installed, also with shield around the primary air inlet (maybe this isn't necessary)

Gas pipe work installed

So this is the first time I'd run it on steam, and of course gas fired.

[ame]http://www.youtube.com/watch?v=-_tMDODla1g[/ame]

Now its freed up it will run on 5 psi and is even quieter now its been run on steam.

Over this past weekend I made a blower out of a computer fan, a plastic funnel and length of 22mm copper pipe

I thought long pipe to keep the temp from the fan (OK how long is that going to last?) . It does the job very well and I've got loads of these cheap fans from dead computers. I can now go from a cold fill, fire up the burner and be at 80psi in 10 mins. I did it again tonight just to confirm it wasn't fluke. I tried to get a video but it didn't come out that well.

Next job is the accumulation test at the club and running on the track.

Pete

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

sbwhart said:Lovely job Pete its given me inspirations for me get my Jumbo finished.

Good luck with the steaming and first run.

Stew

Thanks Stew; and you got the answer quicker than you probably expected. Now you've got to get your Jumbo finished!! ;D

Pete

Brilliant Pete,

Not seen the video yet but well done! When I saw your plastic blower fan must admit I thought 'oh dear' because I tried that for the first one I made and it just melted in a matter of seconds, maybe yours is far enough away!

:bow:

Not seen the video yet but well done! When I saw your plastic blower fan must admit I thought 'oh dear' because I tried that for the first one I made and it just melted in a matter of seconds, maybe yours is far enough away!

:bow:

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Augh! Another thread I shouldn't have popped into.

I love locos.

That's a wonderful job Pete. And congratulations. It sounds great!

I love locos.

That's a wonderful job Pete. And congratulations. It sounds great!

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

NickG said:.......When I saw your plastic blower fan must admit I thought 'oh dear' because I tried that for the first one I made and it just melted in a matter of seconds, maybe yours is far enough away!

Thanks Nick.

I thought no way until somebody at the club turned up with one on a short funnel. He said his worked fine so I decided to give it a go. I can get boiler pressure up to 80psi and still hold the top of the pipe to remove it so its fine. I then go on the engine blower. I do make sure I don't put steam through it but if it goes rusty I'll just stick another one in.

Thanks Matt

No its running in forward just strobeing I'd imagine. A combination of camera saving as .mpeg, Windows movie maker conversion to .wmv and Youtube conversion to flash. Something gets lost en-route.

Yes it has a whistle under the left running board

Thanks Arnold

Looking forward to being able to run it myself. Not far off now

Thanks Ron

Believe me it sounds better in the flesh. Nice and smooth.

Thanks Zee

Hopefully you'll get back to yours and we can see that running as well (change that ball though)

Pete

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

A big day today, the boiler completed its certification and now I can take it onto the track. I don't have a running trolley so one of the club members is going to lend me his 3.5" guage trolley so it will be next weekend, weather permitting. The good thing is its all fitted out for running on on propane so ideal.

It's going to be a slow week............

Pete

It's going to be a slow week............

Pete

Well done Pete on getting your boiler cert. I didn't really have any doubts about it, because of the quality of build. You now have a loco that should last a lifetime if looked after.

I bet you will be dreaming about going around the track all week. Maybe you should give it a bit more air and oil this week, just to bed it in a little more.

John

I bet you will be dreaming about going around the track all week. Maybe you should give it a bit more air and oil this week, just to bed it in a little more.

John

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

Thanks Nick, Thanks John.

Its all coming together nicely; I had intended to get it done by the summer (December in the antipodes) and it looks like I will. I may have mentioned before the club are planning to rip up the 3.5" gauge track and re-build it thus year so I do need to get in quickly before the work starts. Of course I'll have also an interest in assisting getting the new track built.

It nearly had a quick outing today, but just as we tried to start it there was a strange clicking noise. One of the taper pins had come out of the cross head. I hadn't loctite'd them in when I did the valve timing so that was it for the day (it had started raining as well). A clean out with the taper reamer of both sides, just in case they both been loose and gone out of shape, and two new taper pins with loctite fixed it. I may run it again on air but even now, once its started it ticks over nicely on 5psi.

Hopefully the weather will be kind and things will go well. I'm plan to get some video of the event so there may be something posted on here.

Pete

Its all coming together nicely; I had intended to get it done by the summer (December in the antipodes) and it looks like I will. I may have mentioned before the club are planning to rip up the 3.5" gauge track and re-build it thus year so I do need to get in quickly before the work starts. Of course I'll have also an interest in assisting getting the new track built.

It nearly had a quick outing today, but just as we tried to start it there was a strange clicking noise. One of the taper pins had come out of the cross head. I hadn't loctite'd them in when I did the valve timing so that was it for the day (it had started raining as well). A clean out with the taper reamer of both sides, just in case they both been loose and gone out of shape, and two new taper pins with loctite fixed it. I may run it again on air but even now, once its started it ticks over nicely on 5psi.

Hopefully the weather will be kind and things will go well. I'm plan to get some video of the event so there may be something posted on here.

Pete

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

I'm looking forward to the video!

arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Me too ;D - I hope the weather plays along for you!I'm looking forward to the video!

Regards, Arnold

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

Well the weather turned out fine and we went to the track. The riding trolley is on loan from one of the club members. It is fitted out for gas running with the cylinder in a box at the rear with the regulator and gas control valves and gauges at the front.

[ame=http://www.youtube.com/watch?v=GIqaLG1D7wk]http://www.youtube.com/watch?v=GIqaLG1D7wk[/ame]

The sound in the background is the main track with the paying customers taking their kids for a day out. So before you ask, no that's not my horn!

It was a great day and a momentous event. The main problem was maintaining steam pressure enough to get a good run. I kept having to stop and steam up again. Also maintaining water level in the boiler was a bit of an issue, the water tanks had to be filled twice, so the water was going somewhere. (the lever sticking out of the left hand tank is the hand pump)

Certainly I need to look at the burner output to maintain steam pressure. The experienced gas burner guys think I have a problem with primary/secondary air supply. They have plans for a different burner type so I may well try that. Maybe there's also a valve timing problem that needs investigating.

That said, as you can see I'm a big guy and with the trolley, gas cylinder etc the all up weight was 145kg or 320lbs so the little thing did well.

All in all a good day, and all these things can get sorted. I'm happy ;D ;D ;D ;D

Pete

[ame=http://www.youtube.com/watch?v=GIqaLG1D7wk]http://www.youtube.com/watch?v=GIqaLG1D7wk[/ame]

The sound in the background is the main track with the paying customers taking their kids for a day out. So before you ask, no that's not my horn!

It was a great day and a momentous event. The main problem was maintaining steam pressure enough to get a good run. I kept having to stop and steam up again. Also maintaining water level in the boiler was a bit of an issue, the water tanks had to be filled twice, so the water was going somewhere. (the lever sticking out of the left hand tank is the hand pump)

Certainly I need to look at the burner output to maintain steam pressure. The experienced gas burner guys think I have a problem with primary/secondary air supply. They have plans for a different burner type so I may well try that. Maybe there's also a valve timing problem that needs investigating.

That said, as you can see I'm a big guy and with the trolley, gas cylinder etc the all up weight was 145kg or 320lbs so the little thing did well.

All in all a good day, and all these things can get sorted. I'm happy ;D ;D ;D ;D

Pete

Absolutely great Pete.

You can tell from the sound of your voice that you are happy with the outcome. Just a few bits of fine tuning to do and away you go.

I think you and your old man have proved that you can build a great model between you.

John

You can tell from the sound of your voice that you are happy with the outcome. Just a few bits of fine tuning to do and away you go.

I think you and your old man have proved that you can build a great model between you.

John

- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

Thanks John

Yes I was very pleased with the outcome and it is fine tuning is all that is required. With the stop start nature of getting round the track I think the others were more disappointed for me than I was myself.

Today could be looked on as testing, I've always taken the view that the purpose of testing isn't to find out what works but to find out what doesn't. If it had sailed round the track doing a couple of circuits without any problems I'd have learned nothing.

Pete

Yes I was very pleased with the outcome and it is fine tuning is all that is required. With the stop start nature of getting round the track I think the others were more disappointed for me than I was myself.

Today could be looked on as testing, I've always taken the view that the purpose of testing isn't to find out what works but to find out what doesn't. If it had sailed round the track doing a couple of circuits without any problems I'd have learned nothing.

Pete

- Joined

- Nov 14, 2009

- Messages

- 675

- Reaction score

- 104

Well done Pete,a nice video to finish with,I have really enjoyed these posts,I have a mate who has just bought a Rob roy made in Switzerland with metric threads,He has it stripped down so he will find your posts of great interst,

Don

Don