- Joined

- Mar 1, 2010

- Messages

- 865

- Reaction score

- 82

Rather than hijack Stews thread on his 3.5" boiler build

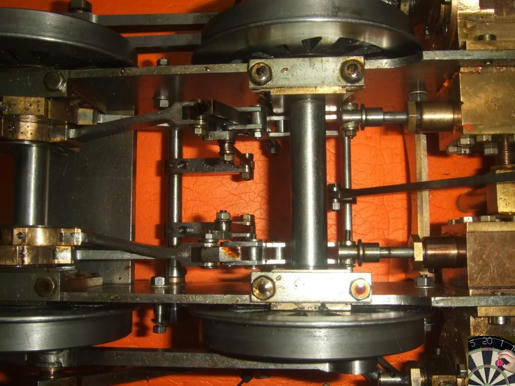

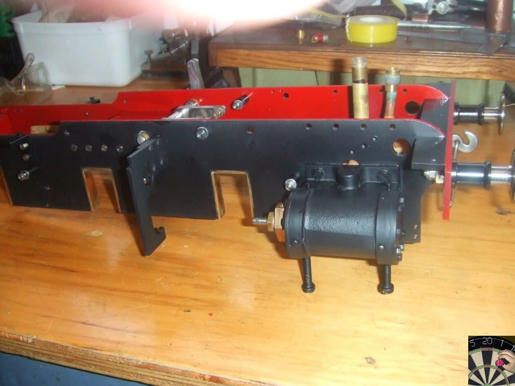

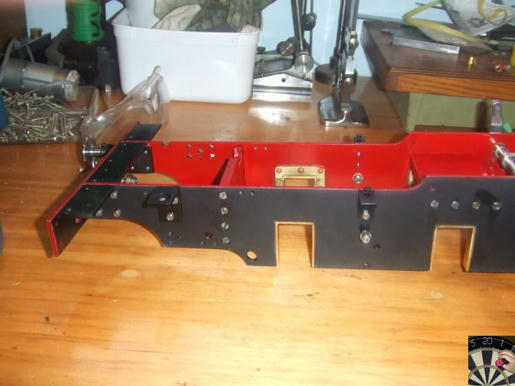

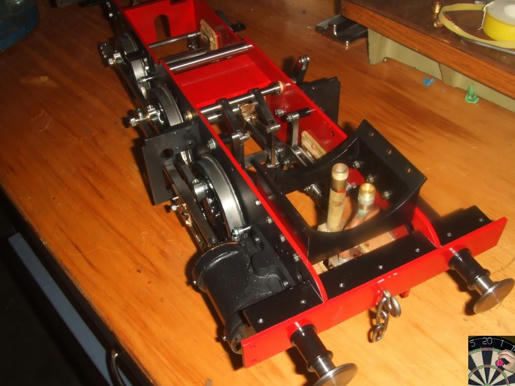

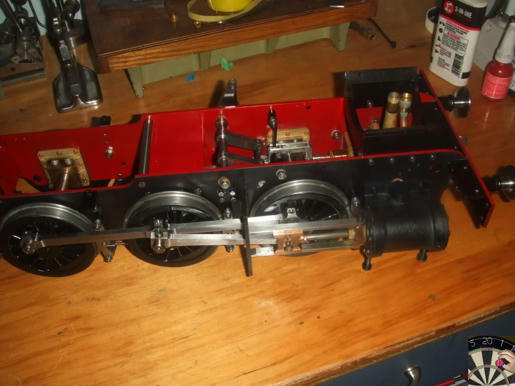

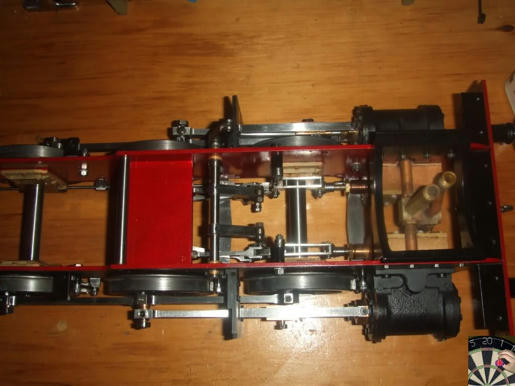

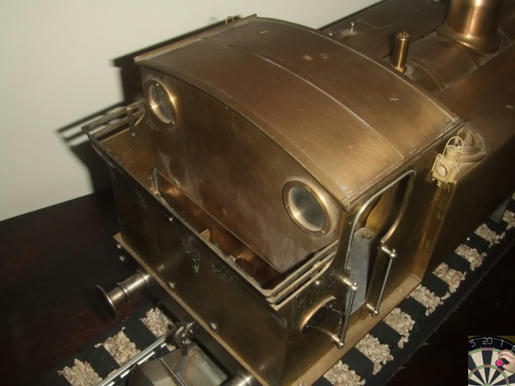

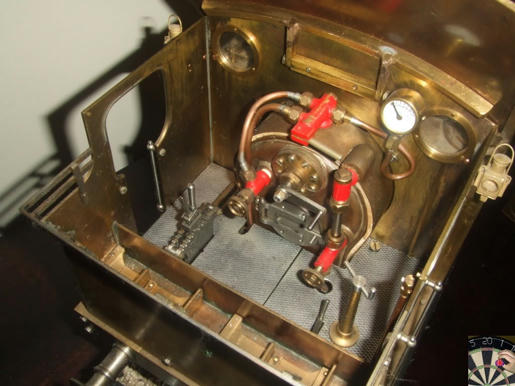

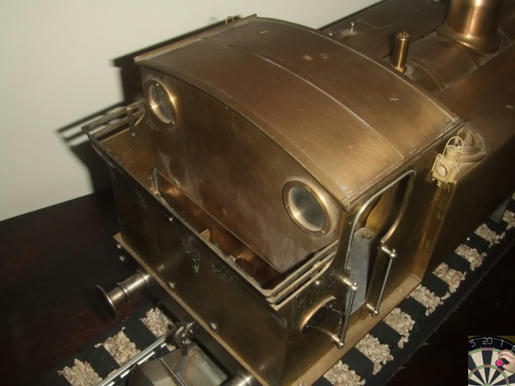

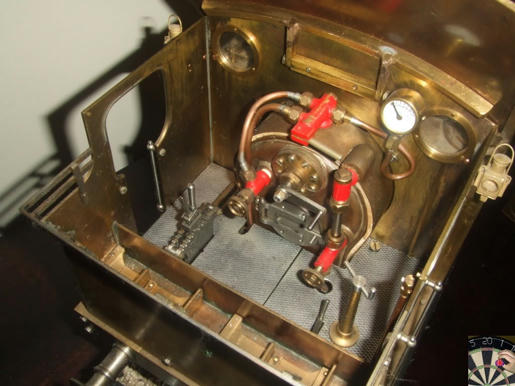

The real reason I'm on this forum is so I can get my skills to a level that I am confident to finish this off without stuffing it up. My dad started this about 1980 and its all a bit dusty as no real work has been done on this engine in about 20 years. I had intended to leave it as it was but now, and as a result of this forum, maybe not.

The damage on the cylinder covers was a a result of not having a jig like Stews and was done in the UK before it came to me. This engine (and the rest of my workshop) traveled unaccompanied to NZ, courtesy of Crown Movers, without any other damage or anything going missing.

It needs a complete strip down and finishing.

As you can see why I am extremely interested in Stews thread.

I'm in no rush to do this and it could be another 20years before I do finish it.

Pete

The real reason I'm on this forum is so I can get my skills to a level that I am confident to finish this off without stuffing it up. My dad started this about 1980 and its all a bit dusty as no real work has been done on this engine in about 20 years. I had intended to leave it as it was but now, and as a result of this forum, maybe not.

The damage on the cylinder covers was a a result of not having a jig like Stews and was done in the UK before it came to me. This engine (and the rest of my workshop) traveled unaccompanied to NZ, courtesy of Crown Movers, without any other damage or anything going missing.

It needs a complete strip down and finishing.

As you can see why I am extremely interested in Stews thread.

I'm in no rush to do this and it could be another 20years before I do finish it.

Pete