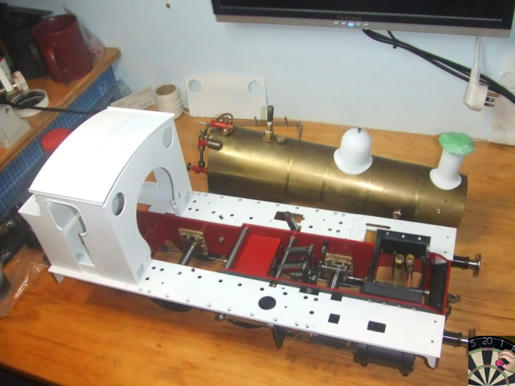

Thanks Nick, I have minimal claim no fame for any of this and I'll admit the boiler was done by a professional boiler maker.

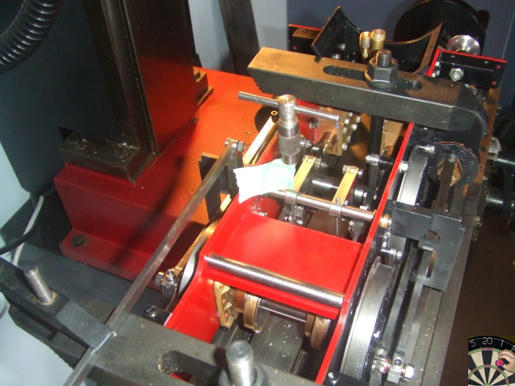

I couldn't wait until the weekend to make an air line adaptor. It occurred to me that I had a whole lot of different bits and bobs that came with my air tools and it wouldn't be the first time something fitted 'out of the box'..................

It did the thread on the air gun nozzle was 3/8" x26 so I was on my way

The first attempt was hopeless air escaping somewhere. I'd left the oiler clack off so the air wasn't getting far. One of my boiler test blanking plugs soon fixed that.

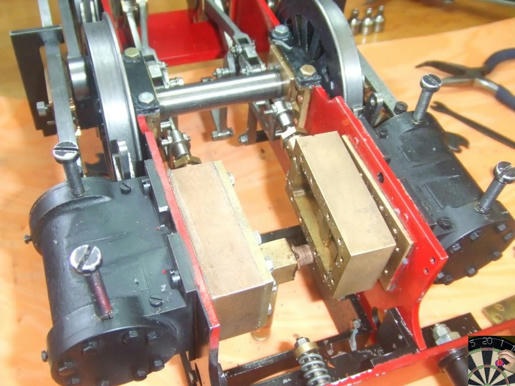

Next attempt wasn't much better, air pouring out of the exhaust pipe and not a hint of movement on the pistons. Ho hum to stiff or something wrong with the timing. Then I remembered my dad saying "make sure you seat the valves first" with no hint of how to do that.

I sat down with the Martin Evans book and no clues in there either. From the drawings there seems to be a big gap between the valve chest cover and the valve slide so a good reason for it to leak.

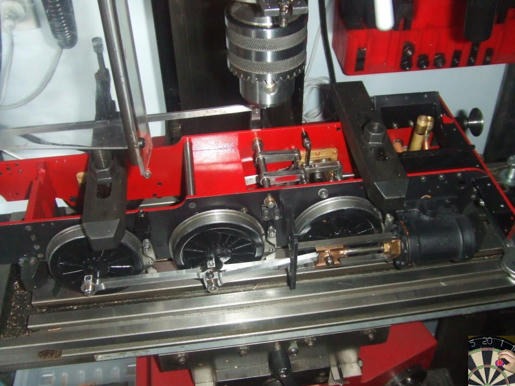

Not wanting to give up now I hand cranked the wheels and reversing arm to work out the relationship between the wheel position, valves and reversing lever. I figured that putting the reversing lever in the 'right' place would allow the valves to seat.

So third attempt and I just waggled the reversing lever about and bang it burst into life.

[ame]http://www.youtube.com/watch?v=cwH2MOvkbBM[/ame]

It's a bit noisy probably a timing issue but as there's no reversing quadrant fitted so the reversing gear is wobbling about a bit and that's probably not helping.

Happy person; and no doubt when he sees this, happy dad ;D

Pete