kd0afk

Well-Known Member

- Joined

- Nov 5, 2012

- Messages

- 558

- Reaction score

- 52

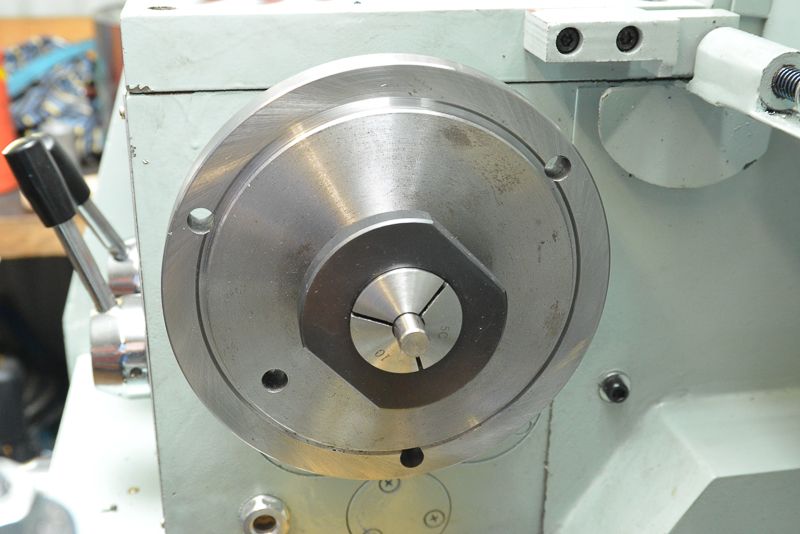

I am reading the latest issue of "The Home Shop Machinist" and in the article about collets it shows a 5c collet chuck. The caption reads;"A system used on the 9" South Bend lathe to allow the use of 5C collets. It works when you can't do better."

What does "..when you can't do better" mean? Is 5C not the best choice for a collet system? I don't understand.

What does "..when you can't do better" mean? Is 5C not the best choice for a collet system? I don't understand.