vcutajar

Well-Known Member

- Joined

- Nov 6, 2011

- Messages

- 863

- Reaction score

- 169

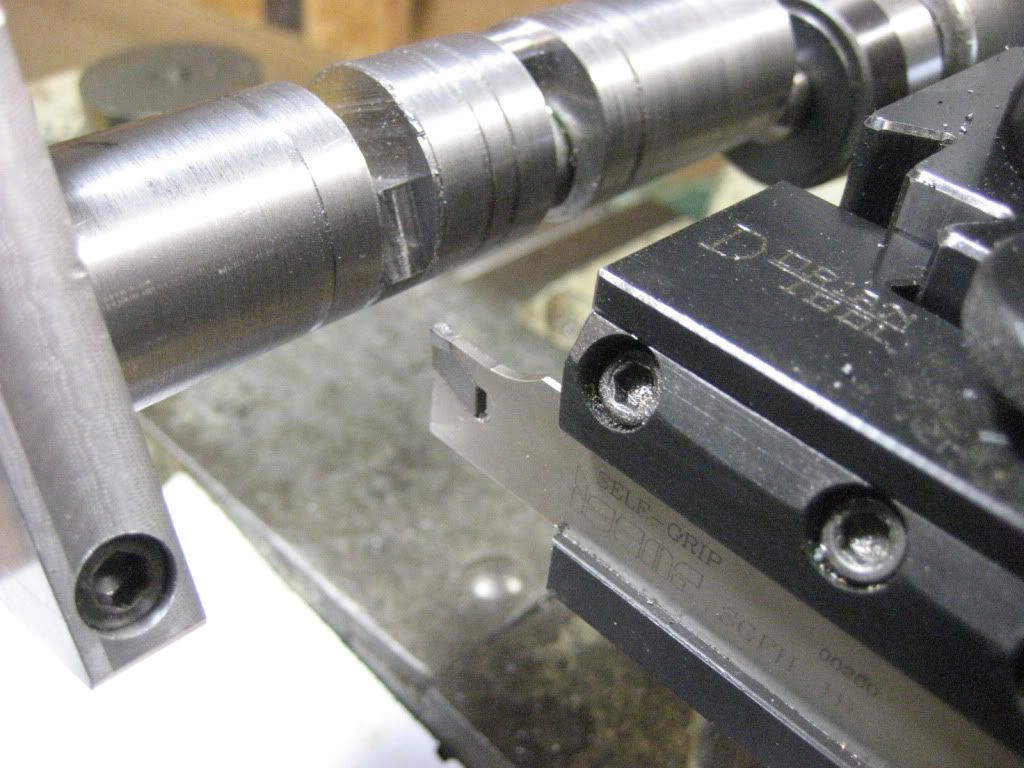

This week I received the Model Engineers' Workshop issue 185 and there was an article which caught my eye. It was about using tipped lathe tools and in it there was mentioned the Q-Cut parting system.

http://www.greenwood-tools.co.uk/shopscr23.html

http://cheappartinginserts.bombog.c...sert-gc1125-grade-r151-shape-high-feed-0-012/

I was looking at the profile of the insert and it seems very similar to the grooved or bifurcated profile that Edgar T. Westbury describes as a tool for making crankshafts.

Has anybody here used this tool with any success especially in making crankshafts?

http://www.greenwood-tools.co.uk/shopscr23.html

http://cheappartinginserts.bombog.c...sert-gc1125-grade-r151-shape-high-feed-0-012/

I was looking at the profile of the insert and it seems very similar to the grooved or bifurcated profile that Edgar T. Westbury describes as a tool for making crankshafts.

Has anybody here used this tool with any success especially in making crankshafts?