You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PatRon: Harmonically Reciprocating Piston Rotary Engine

- Thread starter manolis

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Cogsy

Well-Known Member

You write:

So, you see uneven distribution of the mass of the PatRon piston around its centre of rotation:

Would you be kind enough to show me where you see unevenness of mass distribution?

It's not merely a question of even mass but its' relative position. Your single cylinder is revolving around an axis with its' centre point in the middle of the crankshaft. Although there is a balance web on the opposing side, there is an inequality with a small mass having a large position change in relation to the axis of rotation and a larger mass displacing a smaller relative distance in the opposing direction. This will have an effect on angular velocity if not constrained.

The wankel has equal masses moving in opposing and equally proportionate distances, effectively counteracting the change as it revolves. Of course for all I know the angular velocity may even alter on the wankel but I don't think the designers of that engine made the same claims as you have done.

I have all the good will to answer your questions and correct your wrongs / mistakes / misunderstandings.

But this takes two and a little of good will.

Yet still you fail to answer the previous questions pertaining to the gyroscopic effects, aerodynamic drag, yada, yada, yada, that have been put to you, effectively the quantifiable questions that simply don't agree with your initial claims.

Search in the Patent Officies

And finally the evidence of your real intent - patents serve 1 purpose only - money. You aim to make a profit from your 'wondrous designs' yet you can't directly sell these ideas to the actual market (engine manufacturers)? That only leaves investors as I alluded to in my last response.

I have done a little research and it seems you are correct about the porting design of the GM 2 strokes. I must say that empirically we never noticed any abnormal oil consumption compared to 4 stroke diesels but we never quantified the consumption so it is possible. However, the current design high tech 2 strokes, again referencing the engineering snowmobile challenge (I do wish I could remember the name of the contest) certainly do not use ports and have markedly better emissions than comparable 4 stroke engines.

Finally, and this really will be my final post on this topic, the evidence stacking up against you is overwhelming. You make enormous claims of your designs while omitting things as basic as aerodynamic drag, then simply won't respond to direct questions relating to this 'erroneous' data. All while designing and championing at least 3 wondrous new breakthroughs in multiple engine technologies (rotary valve, rotary engine and now reciprocating piston rotary engine). If you truly believed in any one of your designs you'd surely be devoted to refining, developing and rigorous professional testing of that one design - not bouncing around internet forums with one idea after another, arguing with almost everyone you encounter for no possible gain. Of course if you really, truly had made a design breakthrough near the magnitude you claim, you'd have quietly patented it and sold it off to the highest bidder, of which there would be many. So I think you've wasted enough of my time and goodwill, and this discussion is simply not going anywhere. I won't say good luck but I will say farewell!

Hello Herbiev

You write:

“Are plans available for any of our members who may wish to build this engine. Also a build log of your construction would be helpful”

At http://www.pattakon.com/PatRon/PatRon_HMEM.dxf is a dxf AutoCAD2000 drawing of a PatRon:

that can be used as a basis for designing / making a prototype.

Here is a more “unconventional” PatRon for small airplanes, ultralights etc.:

(the dxf AutoCAD2000 drawing wherein the animation is based is at

http://www.pattakon.com/PatRon/PatRon_HMEM_2.dxf )

It is an over-square direct injection Diesel.

With 120mm bore and 60mm stroke (about as over-square as the Ducati Panigale 1299) it gives a 2-Stroke capacity of 1,350cc.

The maximum dimension of the spinning cylinder is 1ft, i.e. the distance from the top of the one cylinder head to the top of the other cylinder head is only 305mm.

The scavenging is quite strange:

At some angle of the cylinder the piston opens the “leading” port and the pressure of the gas in the cylinder drops sharply.

Several (like 10 or 15) degrees later the piston opens the trailing port, too. The exhaust happens through both ports. Gradually the leading port becomes the intake port with the trailing port being the exhaust port:

The motion of the cylinder in the ambient air pushes air to enter from the leading port to scavenge the cylinder and then to exit from the trailing port.

After the BDC the pistons moves “upwards”; initially it closes the trailing port; the air entering the cylinder from the leading port continues to enter (due to inertia) until the piston closes the leading port, too.

The gas in the cylinder is compressed. Near the TDC diesel fuel is injected into the bowl at the center of the crown of the piston.

After the TDC it follows the expansion.

After the middle stroke the piston opens the leading port (it serves as exhaust port and as intake port) and so on.

I.e. it uses neither crankcase scavenging, nor some external scavenge pump.

If it works, it makes an extremely compact, simple and lightweight Diesel, which is also perfectly balanced, which also provides some 15% longer piston dwell at the TDC as compared to the conventional Diesels (the PatRon running at 5,000 rpm gives to the combustion as much time as a conventional Diesel running at 4,500rpm), and which eliminates the load between the piston skirts and the cylinder liner (the skirts are there to seal the crankcase).

At 5,000rpm of the cylinder (i.e. at 10,000rpm of the crankshaft) it could make some 200bhp (i.e. as much as the Ducati Panigale 1299) because it is a 2-stroke.

As for its weight, 1/4 of the Panigale 1299 engine is reasonable.

As for its Brake Thermal Efficiency, it has all the characteristics for a top BTE.

Thanks

[FONT="]Manolis Pattakos[/FONT]

You write:

“Are plans available for any of our members who may wish to build this engine. Also a build log of your construction would be helpful”

At http://www.pattakon.com/PatRon/PatRon_HMEM.dxf is a dxf AutoCAD2000 drawing of a PatRon:

that can be used as a basis for designing / making a prototype.

Here is a more “unconventional” PatRon for small airplanes, ultralights etc.:

(the dxf AutoCAD2000 drawing wherein the animation is based is at

http://www.pattakon.com/PatRon/PatRon_HMEM_2.dxf )

It is an over-square direct injection Diesel.

With 120mm bore and 60mm stroke (about as over-square as the Ducati Panigale 1299) it gives a 2-Stroke capacity of 1,350cc.

The maximum dimension of the spinning cylinder is 1ft, i.e. the distance from the top of the one cylinder head to the top of the other cylinder head is only 305mm.

The scavenging is quite strange:

At some angle of the cylinder the piston opens the “leading” port and the pressure of the gas in the cylinder drops sharply.

Several (like 10 or 15) degrees later the piston opens the trailing port, too. The exhaust happens through both ports. Gradually the leading port becomes the intake port with the trailing port being the exhaust port:

The motion of the cylinder in the ambient air pushes air to enter from the leading port to scavenge the cylinder and then to exit from the trailing port.

After the BDC the pistons moves “upwards”; initially it closes the trailing port; the air entering the cylinder from the leading port continues to enter (due to inertia) until the piston closes the leading port, too.

The gas in the cylinder is compressed. Near the TDC diesel fuel is injected into the bowl at the center of the crown of the piston.

After the TDC it follows the expansion.

After the middle stroke the piston opens the leading port (it serves as exhaust port and as intake port) and so on.

I.e. it uses neither crankcase scavenging, nor some external scavenge pump.

If it works, it makes an extremely compact, simple and lightweight Diesel, which is also perfectly balanced, which also provides some 15% longer piston dwell at the TDC as compared to the conventional Diesels (the PatRon running at 5,000 rpm gives to the combustion as much time as a conventional Diesel running at 4,500rpm), and which eliminates the load between the piston skirts and the cylinder liner (the skirts are there to seal the crankcase).

At 5,000rpm of the cylinder (i.e. at 10,000rpm of the crankshaft) it could make some 200bhp (i.e. as much as the Ducati Panigale 1299) because it is a 2-stroke.

As for its weight, 1/4 of the Panigale 1299 engine is reasonable.

As for its Brake Thermal Efficiency, it has all the characteristics for a top BTE.

Thanks

[FONT="]Manolis Pattakos[/FONT]

Hello all.

(the same animation at slow motion is at http://www.pattakon.com/PatRon/PatRon_Model_2_Slow.gif )

Regarding the unconventional scavenging mentioned in the post, the above animation may help in understanding how it works/

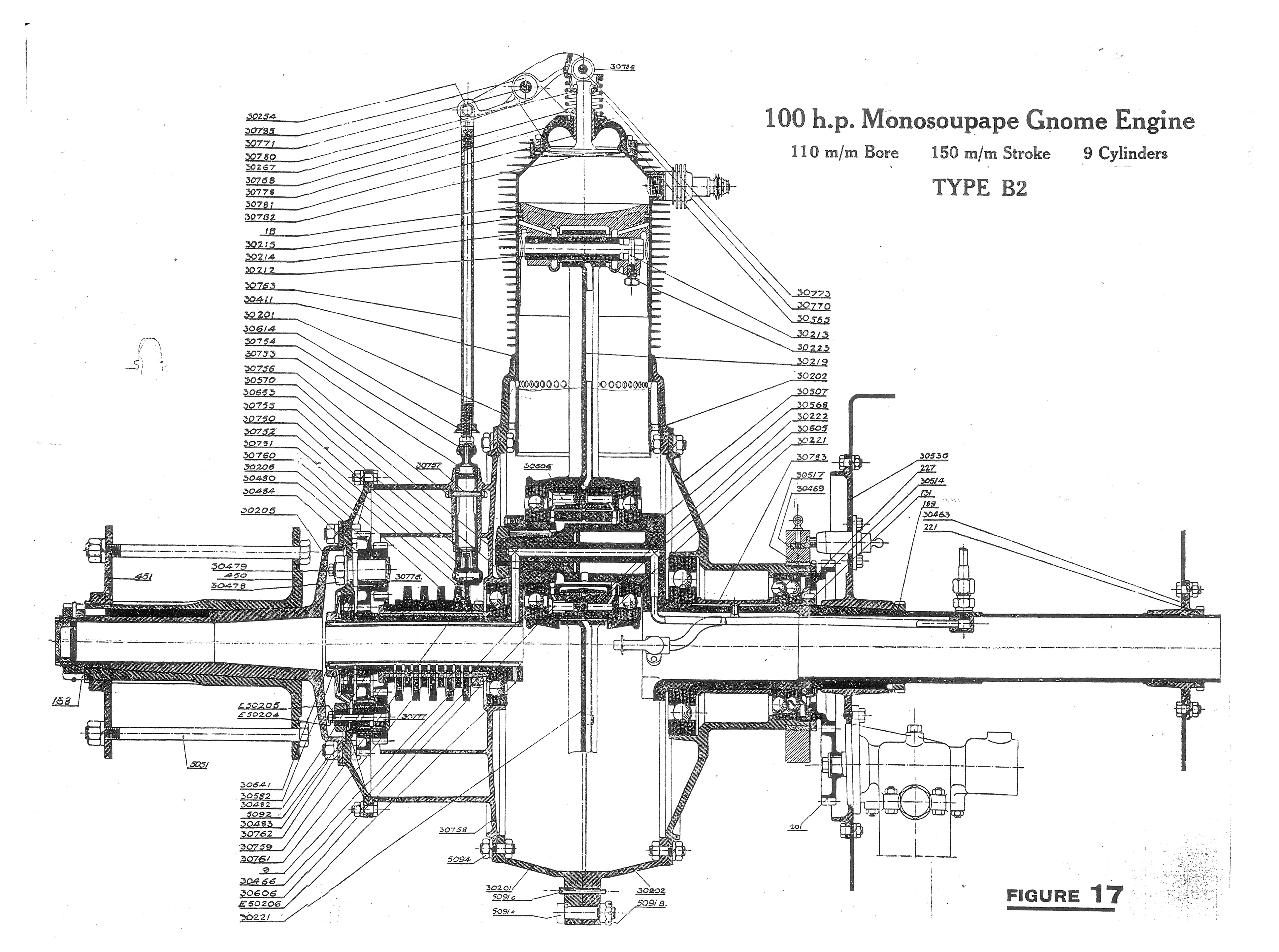

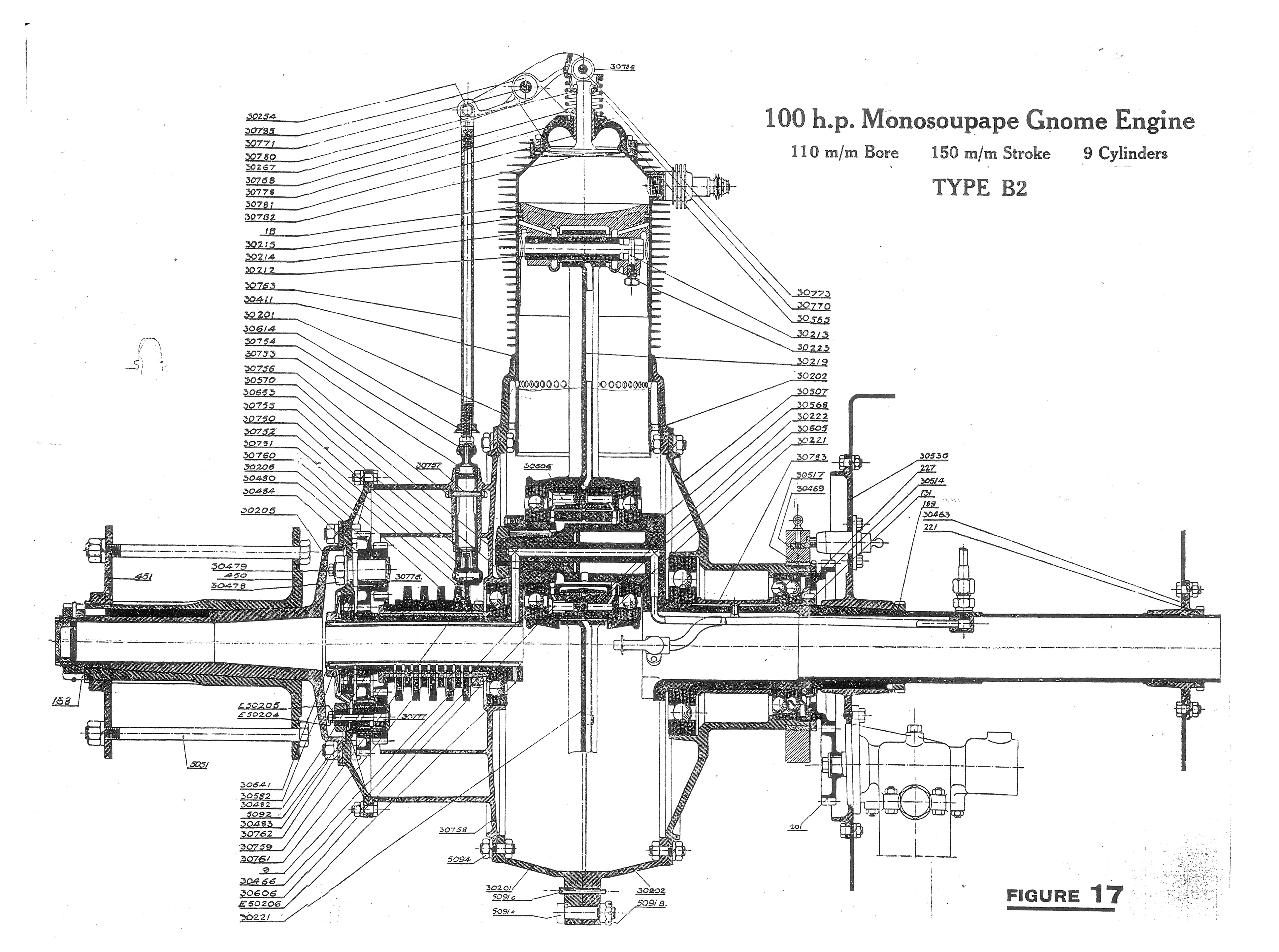

It resembles to the way the Gnome and Rhone rotary engines (those with the ports on the cylinder liner) were running:

(more details at http://thevintageaviator.co.nz/projects/engines/gnome-9b-2-engine/historyv )

They were using the "exhaust" valve of a cylinder unconventionally: initially it was acting as an exhaust valve (during the last half of the expansion cycle and during the exhaust cycle), later (during the intake / admission cycle) it was acting as an intake valve allowing fresh "unfiltered" air to fill the cylinder; at the end of the inlet cycle rich air/fuel mixture was entering into the cylinder through the ports on the cylinder liner.

[FONT="]

Thanks

Manolis Pattakos[/FONT]

(the same animation at slow motion is at http://www.pattakon.com/PatRon/PatRon_Model_2_Slow.gif )

Regarding the unconventional scavenging mentioned in the post, the above animation may help in understanding how it works/

It resembles to the way the Gnome and Rhone rotary engines (those with the ports on the cylinder liner) were running:

(more details at http://thevintageaviator.co.nz/projects/engines/gnome-9b-2-engine/historyv )

They were using the "exhaust" valve of a cylinder unconventionally: initially it was acting as an exhaust valve (during the last half of the expansion cycle and during the exhaust cycle), later (during the intake / admission cycle) it was acting as an intake valve allowing fresh "unfiltered" air to fill the cylinder; at the end of the inlet cycle rich air/fuel mixture was entering into the cylinder through the ports on the cylinder liner.

[FONT="]

Thanks

Manolis Pattakos[/FONT]

Hello all.

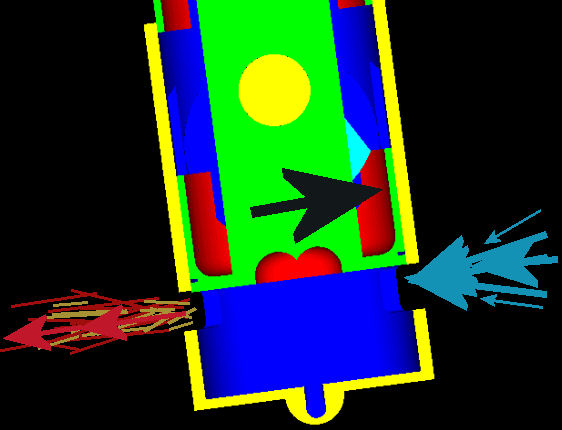

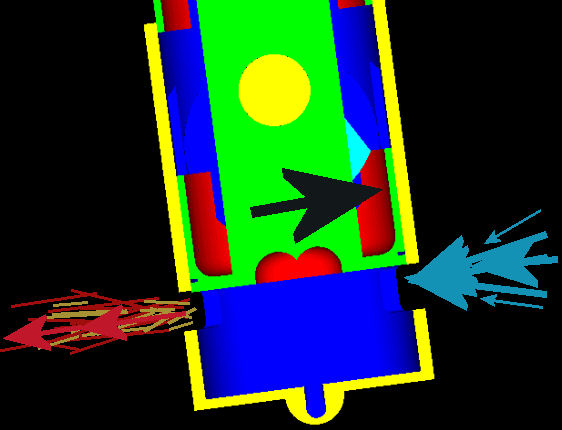

Yesterday, in another forum a guy (CheapRacer) published this drawing :

and wrote:

“at BDC the exhaust helps drive it 'round while the open intake mouth gets self-supercharged!”

The combustion chamber is like a long room (say, a corridor) having a big window towards the north and another big window towards the south.

Outside the room there is a strong wind coming from the north (this is what the rotation of the cylinder causes).

At the end of the expansion the north window opens.

The high pressure in the room pushes a big part of the “gas” to exit from the north window and the pressure to drop sharply.

A little later the south window opens allowing gas to exit from that window too.

Due to the north wind, the flow from the north window gradually weakens, stops and reverses its direction, while the flow from the south window strengthens.

With both windows wide open (BDC), the strong north wind enters from the north window, scavenges the room (and cools down the walls, the ceiling and the floor of the room from within) and exits from the south window.

Later the south window closes, with the north window still open.

The north wind continues to enter into the room from the north window (due to inertia / ram effect) overfilling the room with air (a kind of asymmetrical port timing: the exhaust closes before the transfer).

Finally the north window of the room closes trapping the air entered, and the compression starts.

Thanks

Manolis Pattakos

Yesterday, in another forum a guy (CheapRacer) published this drawing :

and wrote:

“at BDC the exhaust helps drive it 'round while the open intake mouth gets self-supercharged!”

The combustion chamber is like a long room (say, a corridor) having a big window towards the north and another big window towards the south.

Outside the room there is a strong wind coming from the north (this is what the rotation of the cylinder causes).

At the end of the expansion the north window opens.

The high pressure in the room pushes a big part of the “gas” to exit from the north window and the pressure to drop sharply.

A little later the south window opens allowing gas to exit from that window too.

Due to the north wind, the flow from the north window gradually weakens, stops and reverses its direction, while the flow from the south window strengthens.

With both windows wide open (BDC), the strong north wind enters from the north window, scavenges the room (and cools down the walls, the ceiling and the floor of the room from within) and exits from the south window.

Later the south window closes, with the north window still open.

The north wind continues to enter into the room from the north window (due to inertia / ram effect) overfilling the room with air (a kind of asymmetrical port timing: the exhaust closes before the transfer).

Finally the north window of the room closes trapping the air entered, and the compression starts.

Thanks

Manolis Pattakos

Hello all.

In the GIF video-animation here:

they are shown the spinning cylinder (it is from a Honda C-50), the spinning crankshaft (you can see its main journal spinning about a stationary axis, you can also see the crankpin of the crankshaft holding the piston rod that holds the piston head (which is also from a Honda C-50) that reciprocates inside the spinning cylinder.

In the following GIF_video_animation:

the piston have been removed to show the spinning crankshaft and the spinning cylinder.

The only orbiting thing in this video is the crankpin.

The previous GIF_videos at slow motion are at

http://www.pattakon.com/PatRon/PatRo...deo_1_Slow.gif

and

http://www.pattakon.com/PatRon/PatRo...deo_2_Slow.gif

Here is another GIF video-animation showng the spinning crankshaft and the orbiting-spinning piston (the piston head is from a Honda C50):

The same video-animation in slow motion is at http://www.pattakon.com/PatRon/PatRo...deo_3_Slow.gif

Thanks

Manolis Pattakos

In the GIF video-animation here:

they are shown the spinning cylinder (it is from a Honda C-50), the spinning crankshaft (you can see its main journal spinning about a stationary axis, you can also see the crankpin of the crankshaft holding the piston rod that holds the piston head (which is also from a Honda C-50) that reciprocates inside the spinning cylinder.

In the following GIF_video_animation:

the piston have been removed to show the spinning crankshaft and the spinning cylinder.

The only orbiting thing in this video is the crankpin.

The previous GIF_videos at slow motion are at

http://www.pattakon.com/PatRon/PatRo...deo_1_Slow.gif

and

http://www.pattakon.com/PatRon/PatRo...deo_2_Slow.gif

Here is another GIF video-animation showng the spinning crankshaft and the orbiting-spinning piston (the piston head is from a Honda C50):

The same video-animation in slow motion is at http://www.pattakon.com/PatRon/PatRo...deo_3_Slow.gif

Thanks

Manolis Pattakos

Hello all.

The following animations are for a more compact version of the PatRon 2-stroke direct injection Diesel for small airplanes etc, mentioned in previous posts.

For the same bore (120mm) and piston stroke (60mm) the maximum dimesnion of the rotating cylinder is only 280mm (11 inches).

The cylinder head to cylinder head distance is 240mm.

The piston crown to piston crown distance is 180mm.

The slow motion animations are at:

http://www.pattakon.com/PatRon/PatRon_Air_1_Slow.gif

http://www.pattakon.com/PatRon/PatRon_Air_2_Slow.gif

http://www.pattakon.com/PatRon/PatRon_Air_3_Slow.gif

and

http://www.pattakon.com/PatRon/PatRon_Air_4_Slow.gif

Thanks

Manolis Pattakos

The following animations are for a more compact version of the PatRon 2-stroke direct injection Diesel for small airplanes etc, mentioned in previous posts.

For the same bore (120mm) and piston stroke (60mm) the maximum dimesnion of the rotating cylinder is only 280mm (11 inches).

The cylinder head to cylinder head distance is 240mm.

The piston crown to piston crown distance is 180mm.

The slow motion animations are at:

http://www.pattakon.com/PatRon/PatRon_Air_1_Slow.gif

http://www.pattakon.com/PatRon/PatRon_Air_2_Slow.gif

http://www.pattakon.com/PatRon/PatRon_Air_3_Slow.gif

and

http://www.pattakon.com/PatRon/PatRon_Air_4_Slow.gif

Thanks

Manolis Pattakos

Similar threads

- Replies

- 4

- Views

- 3K

- Replies

- 61

- Views

- 11K

- Replies

- 43

- Views

- 10K

- Replies

- 19

- Views

- 7K