DICKEYBIRD

Well-Known Member

- Joined

- Sep 27, 2007

- Messages

- 653

- Reaction score

- 46

I've been wanting to build one of these for quite a while and finally got around to it. Bob Warfield's is way cool with its split cotter clamps and knurled knobs but I chickened out & just did what I'm more familiar with.

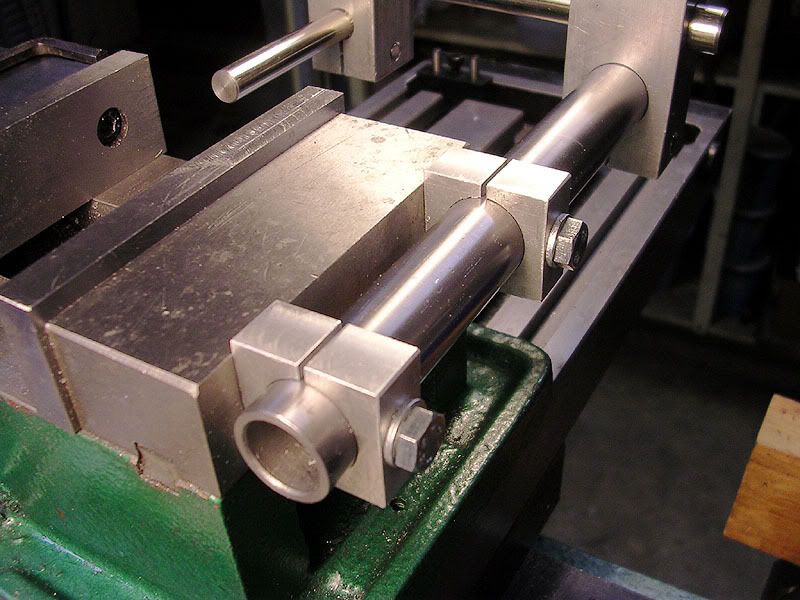

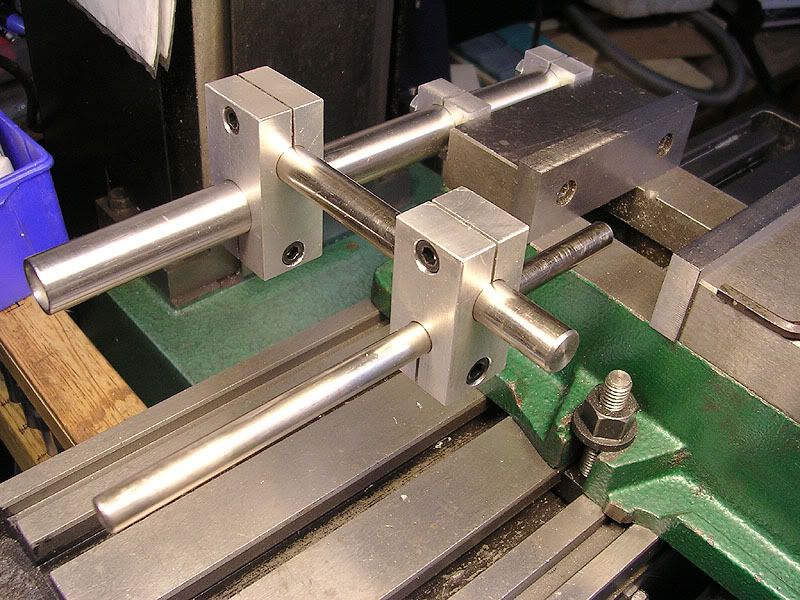

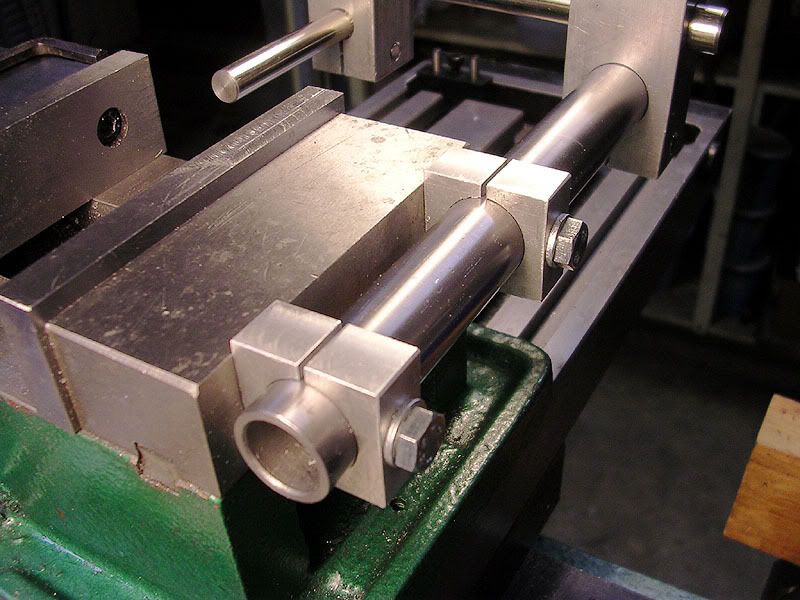

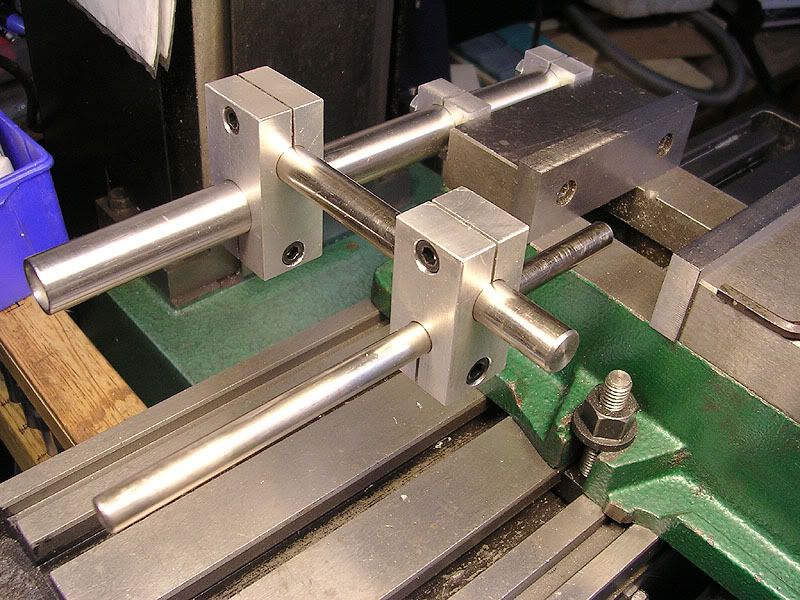

The main shaft is .750" o.d, .090" wall seamless chromoly tubing and the smaller shafts are .5" and .375" polished shafts from old inkjet printers. I used 1" aluminum plate for the clamps rather than round stock since it was easier to keep the holes square as they were bored & reamed. The thing really clamps up tight and is plenty rigid. The whole thing rotates up & out of the way when not in use.

I made some little clamp blocks to mount the shaft to the back of the vise so the tubing wouldn't be crushed. I bored them a few thou under and after they were slit apart, they grip the shaft with a vengeance.

The main shaft is .750" o.d, .090" wall seamless chromoly tubing and the smaller shafts are .5" and .375" polished shafts from old inkjet printers. I used 1" aluminum plate for the clamps rather than round stock since it was easier to keep the holes square as they were bored & reamed. The thing really clamps up tight and is plenty rigid. The whole thing rotates up & out of the way when not in use.

I made some little clamp blocks to mount the shaft to the back of the vise so the tubing wouldn't be crushed. I bored them a few thou under and after they were slit apart, they grip the shaft with a vengeance.