tpeters910

New Member

- Joined

- Sep 24, 2013

- Messages

- 3

- Reaction score

- 0

Hi! New member on for first time. Some background: I was a tool & die maker building precision progressive dies for 20 years, but that ended 15 years ago. Ran all the typical machines, liked them, and very familiar with them. Or so I thought...

Always missed not having access to machines to fix things around the house when I left the tool & die field. Today I find myself the new owner of a 30 year old MSC 8x30 knee mill that needs some attention.

When I worked in the shop, I always liked the feel of the Bridgeport table lock handles, and found they just "fit" my hands better than some of the import/knock-off machine lock handles did. So fast forward to my "new" MSC mill, the PO messed up most of the hardware on the machine.

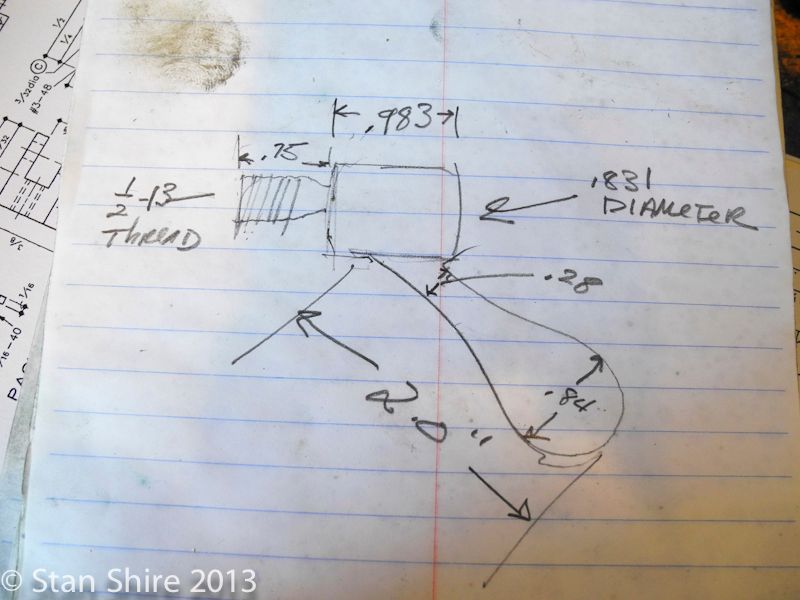

For today's question I am working on the table locks, handles, and plungers. He threw away whatever came on the machine for the table/saddle/knee locks & handles. He drilled the metric threads out to 5/16-18, then pressed knurled head knobs over SHCS to replace the stock locks. No real way to exert any force on them, and don't feel good in my hands. So I have to make the plungers, but the handles/locks are a problem since I don't know what they should be.

I can buy Bridgeport handles/locks, but they don't come close to fitting this machine, so I was thinking of making them myself. Since I do not have a lathe I am sure it will be a challenge to make these with just the mill, but have to deal with what you have to work with. Was thinking to make it easier on limited shop to just use a SHCS, bore a hole in the handle body end, press the handle body on the SHCS, then just drill the hole for the lock handle at desired angle.

Anybody have a Bridgeport who could measure the length of the lock handle, large and small diameters of the lock handle, and angle the lock handles are drilled into the lock stem body at (or just the distance from end of lock handle to the table)?

Any help appreciated,

Tom

Always missed not having access to machines to fix things around the house when I left the tool & die field. Today I find myself the new owner of a 30 year old MSC 8x30 knee mill that needs some attention.

When I worked in the shop, I always liked the feel of the Bridgeport table lock handles, and found they just "fit" my hands better than some of the import/knock-off machine lock handles did. So fast forward to my "new" MSC mill, the PO messed up most of the hardware on the machine.

For today's question I am working on the table locks, handles, and plungers. He threw away whatever came on the machine for the table/saddle/knee locks & handles. He drilled the metric threads out to 5/16-18, then pressed knurled head knobs over SHCS to replace the stock locks. No real way to exert any force on them, and don't feel good in my hands. So I have to make the plungers, but the handles/locks are a problem since I don't know what they should be.

I can buy Bridgeport handles/locks, but they don't come close to fitting this machine, so I was thinking of making them myself. Since I do not have a lathe I am sure it will be a challenge to make these with just the mill, but have to deal with what you have to work with. Was thinking to make it easier on limited shop to just use a SHCS, bore a hole in the handle body end, press the handle body on the SHCS, then just drill the hole for the lock handle at desired angle.

Anybody have a Bridgeport who could measure the length of the lock handle, large and small diameters of the lock handle, and angle the lock handles are drilled into the lock stem body at (or just the distance from end of lock handle to the table)?

Any help appreciated,

Tom