JLeatherman

Well-Known Member

- Joined

- Nov 12, 2012

- Messages

- 93

- Reaction score

- 44

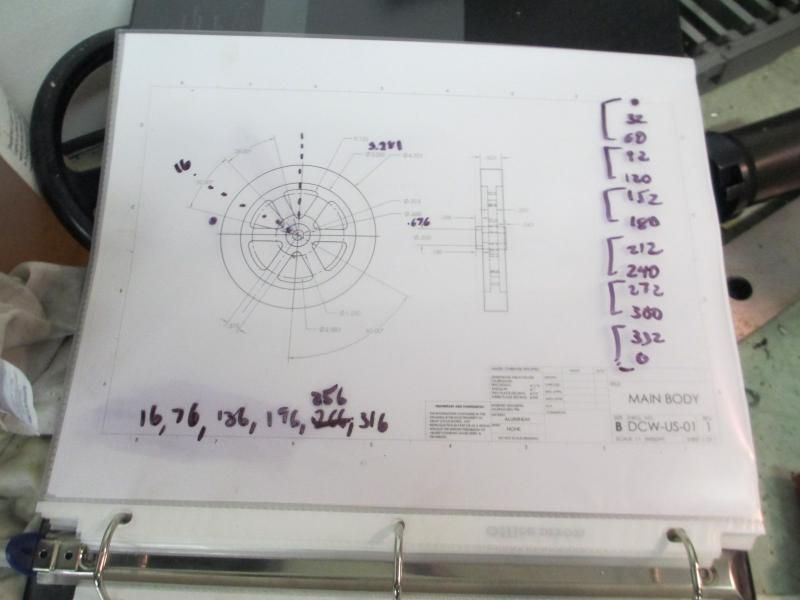

I haven't done a lot of machining this year, but it's Christmas time again and I'm going to try and build my first I.C. engine for my Father's present. Two years ago I built him a "Poppin" and he loved it. I've decided to build something along the lines of a Webster, with a few changes such as:

Roller Rocker

Larger Flywheel with Spokes

Larger Cooling Fins and Fan

Viton Piston Ring

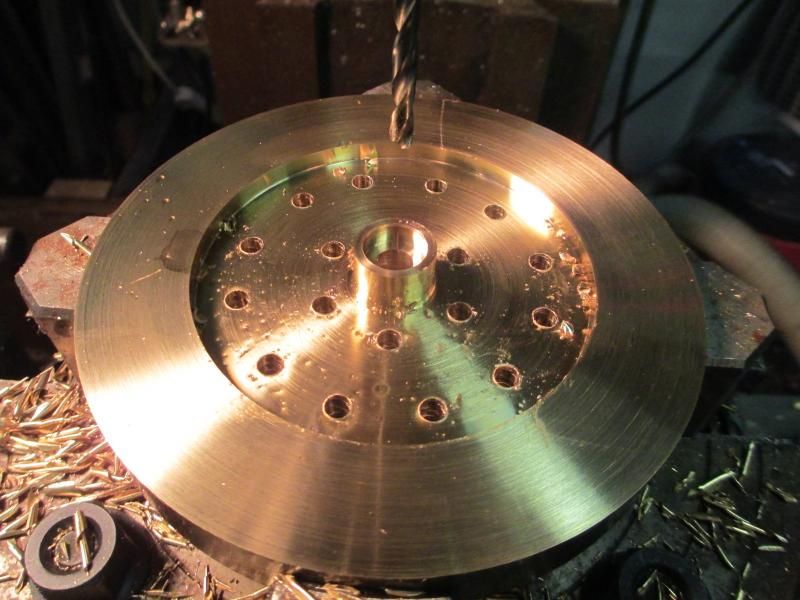

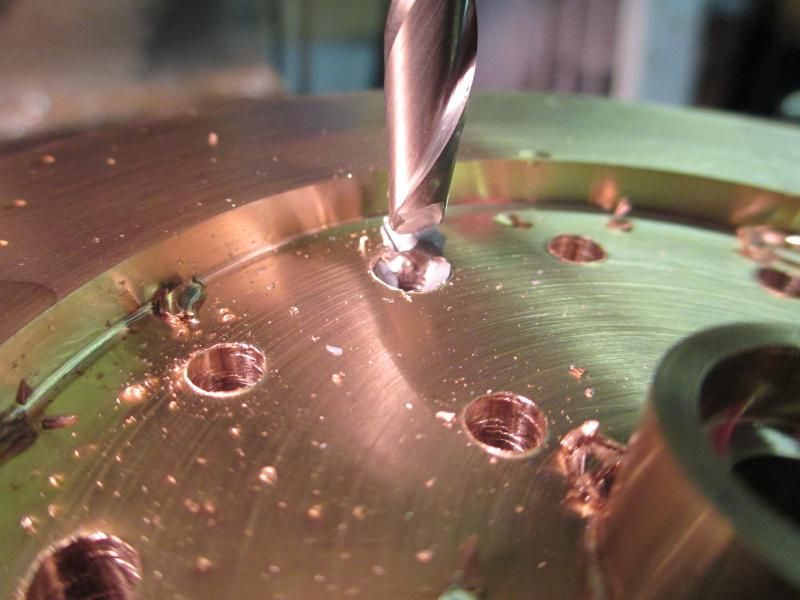

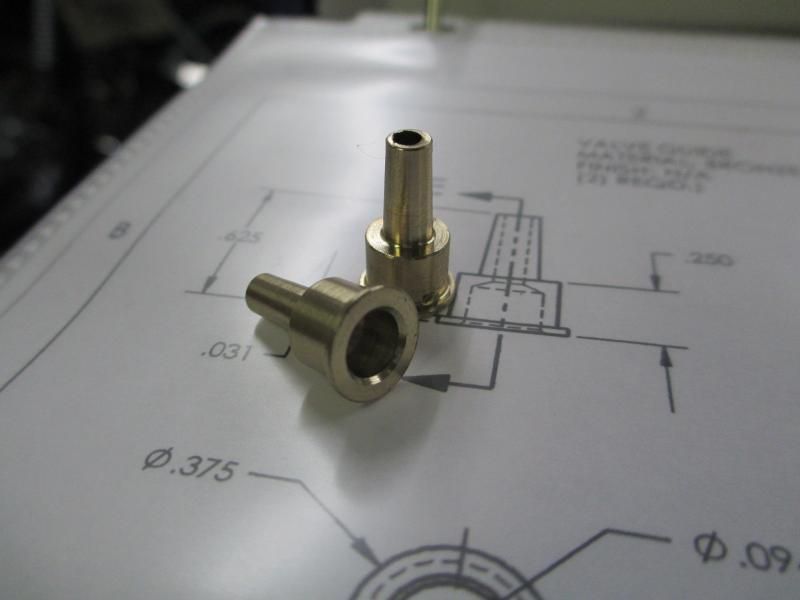

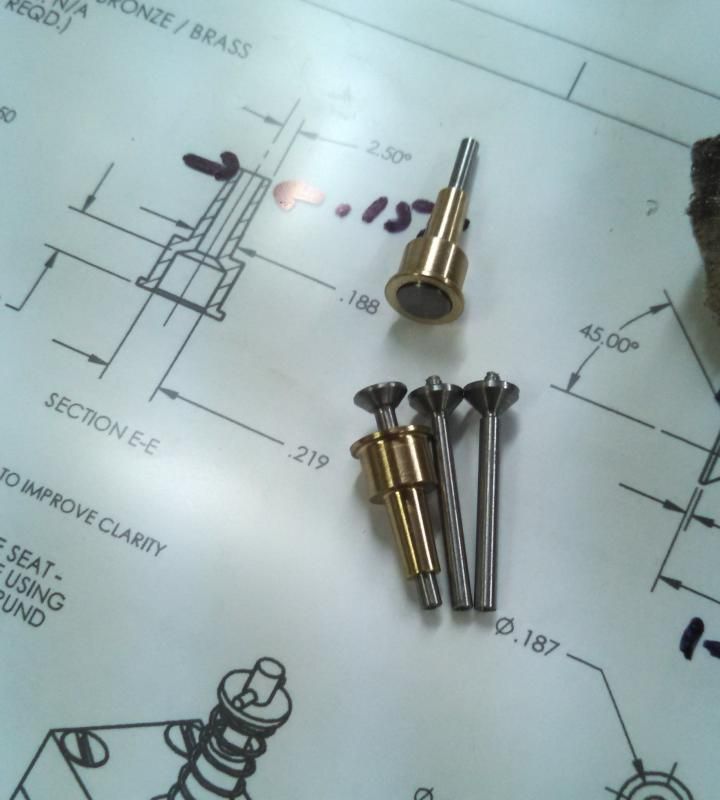

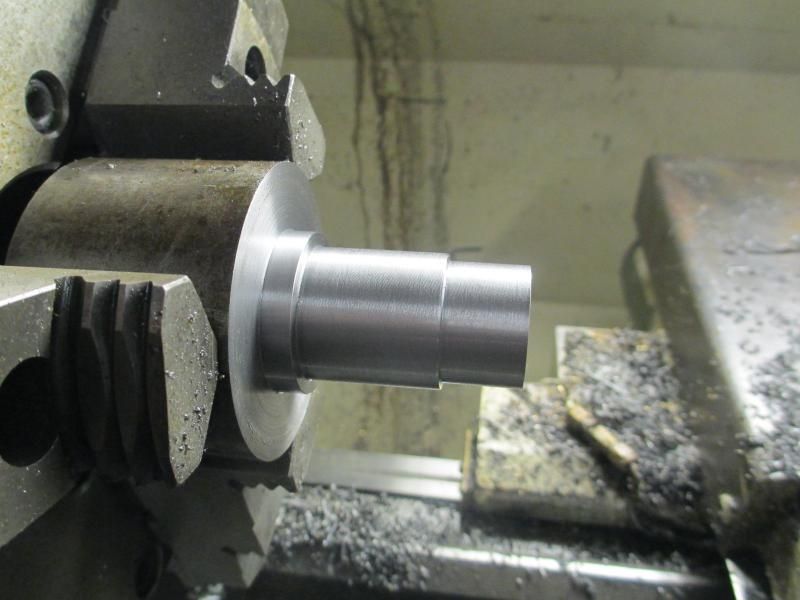

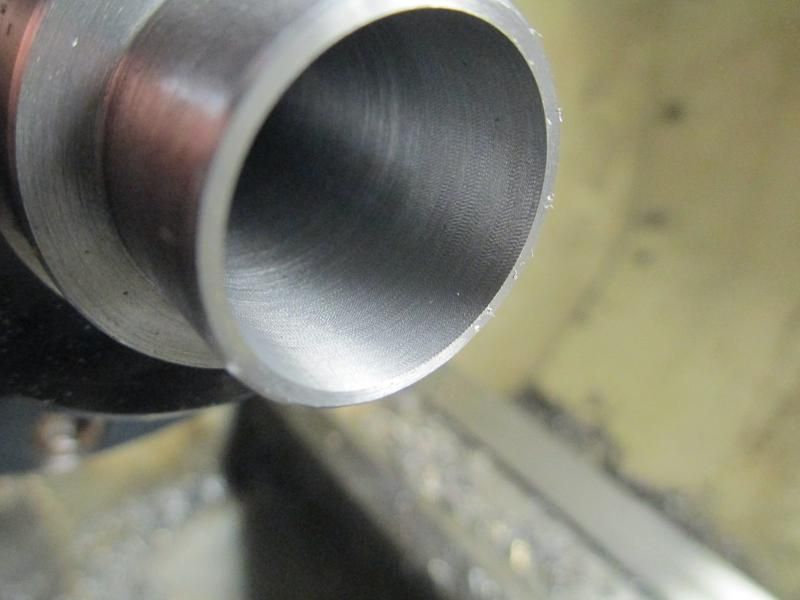

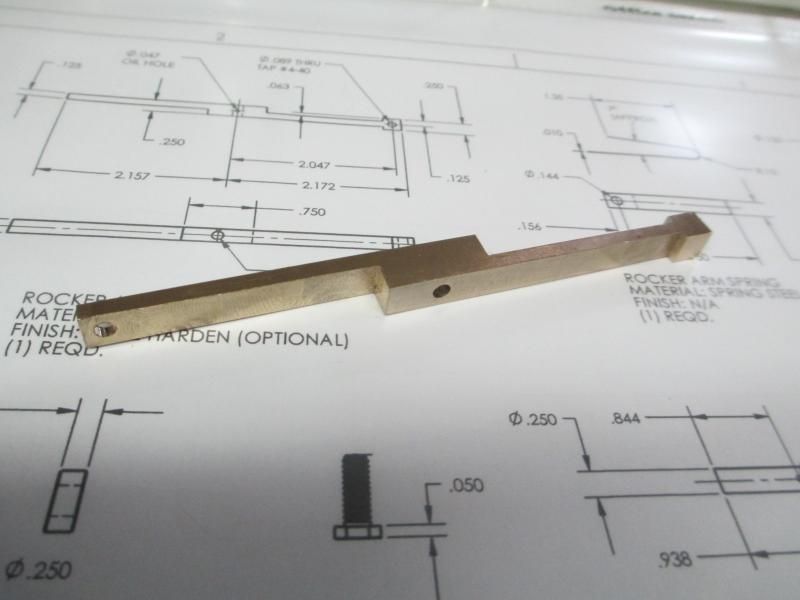

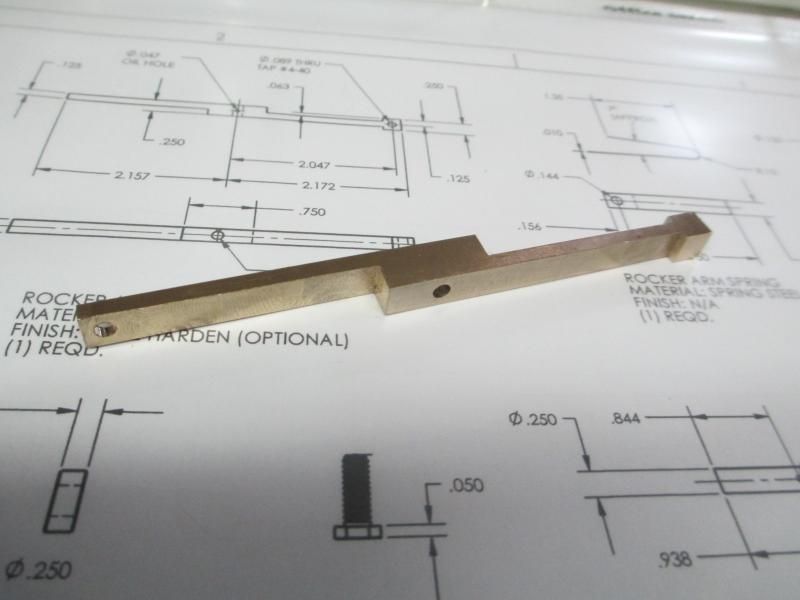

I have some questions as this build progresses. I was going to post this earlier and get the questions out of the way, but I made myself wait until I had cut some metal (otherwise it's not "In Progress" yet). Tonight I started on the rocker first. I had some 932 bearing-bronze sheet left over from making a new gib for my lathe this year. It's .030" shorter than the plans call for, but I can work around that and I'm not buying another piece. I started by using a slitting saw to slice it close to width and then cleaned it up with an endmill.

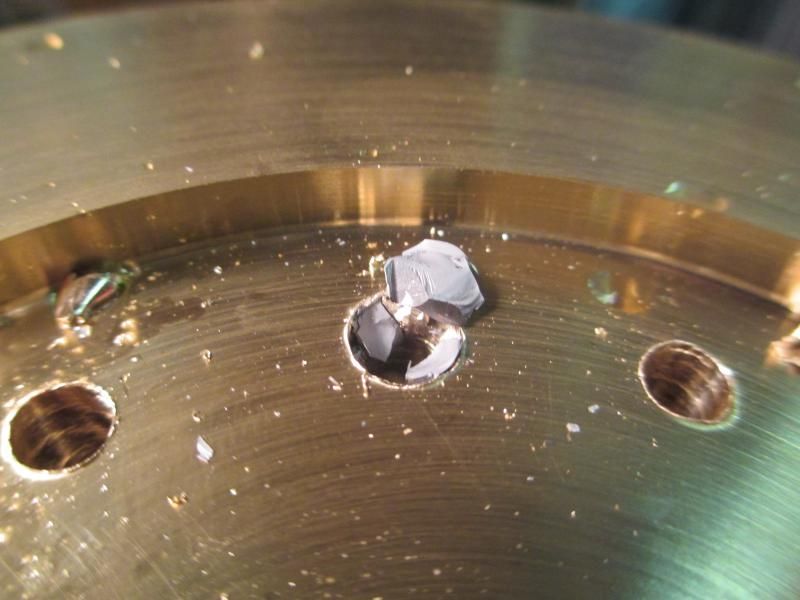

Next I bored the center hole and at this point created my first piece of scrap by reading the wrong dimension off the print (the distance from the pushrod hole as opposed to the front edge of the rocker). I had just enough bronze left for another part, and got the hole bored correctly so I could move on to profiling one side.

I flipped it over and profiled the other side, and the rocker is complete except for the tapped pushrod hole:

That's all for tonight. Hope to get some more done this weekend.

Roller Rocker

Larger Flywheel with Spokes

Larger Cooling Fins and Fan

Viton Piston Ring

I have some questions as this build progresses. I was going to post this earlier and get the questions out of the way, but I made myself wait until I had cut some metal (otherwise it's not "In Progress" yet). Tonight I started on the rocker first. I had some 932 bearing-bronze sheet left over from making a new gib for my lathe this year. It's .030" shorter than the plans call for, but I can work around that and I'm not buying another piece. I started by using a slitting saw to slice it close to width and then cleaned it up with an endmill.

Next I bored the center hole and at this point created my first piece of scrap by reading the wrong dimension off the print (the distance from the pushrod hole as opposed to the front edge of the rocker). I had just enough bronze left for another part, and got the hole bored correctly so I could move on to profiling one side.

I flipped it over and profiled the other side, and the rocker is complete except for the tapped pushrod hole:

That's all for tonight. Hope to get some more done this weekend.