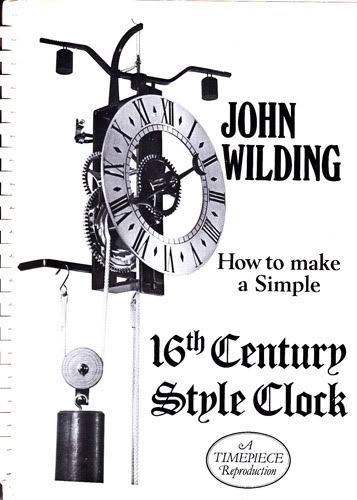

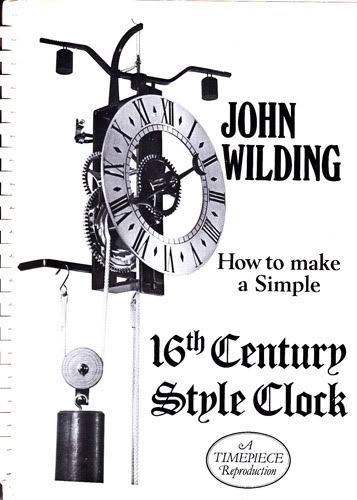

Last June I purchased this book off ebay.

Since last July I have been making the tools I need to make this clock and purchasing material.

I still have more material to get and more tools to make, but I've finally reached a point where I can start.

Here are some of the tools I've made so far for this project.

From top left to right the tools are.

Honing jig for the wheel cutters.

Chamfering tool for the steady pins, its still not finished yet.

Deburing tools for holes smaller than 1/8 inch

Simple riveting anvil.

Fly cutter holder and flycutter for the clock wheels. Still need to make the wheel blank holder.

Screw holder to allow me to shape the ends of the screws, still need to make a few more different sized collets for the holder.

Graver for hand shaping brass.

Clock frame holders to hold the frame off the workbench when fitting the pivots.

Finally a finger clamp, I made this for clock making but I use it all the time for other things too.

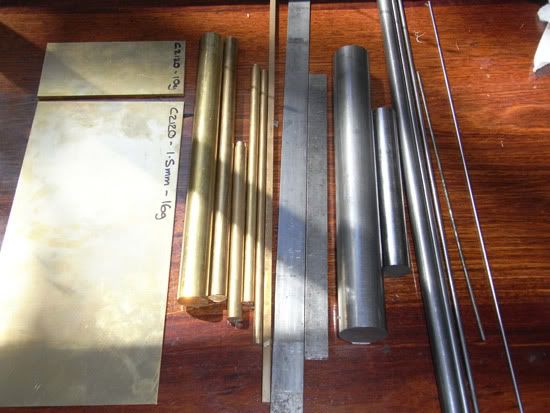

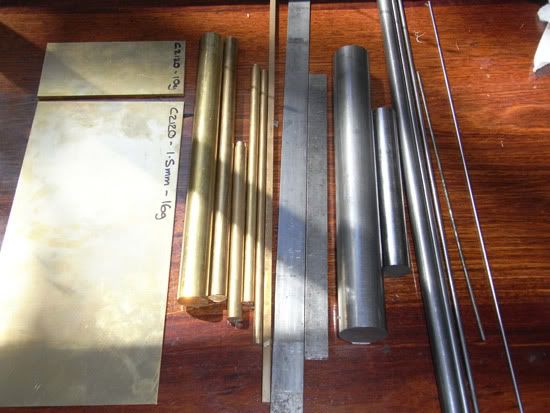

The material needed for the clock. I still am missing a few bits, namely the 1 inch by 1/8 inch BMS for the frame and the 1 5/8 inch BS 2874 brass for the crown wheel, but I now have enough to start.

This will be a slow project as I will need to take a number of detours making extra tools along the way and also purchase a few other items I can't make.

I figure as this is based on a clock design that is around 400 years old that if people could make it with no power tools or accurate measuring items I should be able to. :big:

Since last July I have been making the tools I need to make this clock and purchasing material.

I still have more material to get and more tools to make, but I've finally reached a point where I can start.

Here are some of the tools I've made so far for this project.

From top left to right the tools are.

Honing jig for the wheel cutters.

Chamfering tool for the steady pins, its still not finished yet.

Deburing tools for holes smaller than 1/8 inch

Simple riveting anvil.

Fly cutter holder and flycutter for the clock wheels. Still need to make the wheel blank holder.

Screw holder to allow me to shape the ends of the screws, still need to make a few more different sized collets for the holder.

Graver for hand shaping brass.

Clock frame holders to hold the frame off the workbench when fitting the pivots.

Finally a finger clamp, I made this for clock making but I use it all the time for other things too.

The material needed for the clock. I still am missing a few bits, namely the 1 inch by 1/8 inch BMS for the frame and the 1 5/8 inch BS 2874 brass for the crown wheel, but I now have enough to start.

This will be a slow project as I will need to take a number of detours making extra tools along the way and also purchase a few other items I can't make.

I figure as this is based on a clock design that is around 400 years old that if people could make it with no power tools or accurate measuring items I should be able to. :big: