hello to all in this great forum!

well, I don't know if this is the right section for this post. probably I can't document every step of the work, because I get some photos only by chance, when I remember to do it...

and I have nothing to teach to anybody! I'm new to this hobby, this is my second engine, the first being the steam engine from the brian rupnow plans.

but perhaps sharing this work could be interesting anyway, so here there are the pieces I have done till now

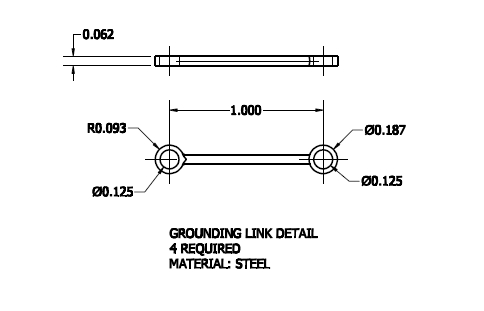

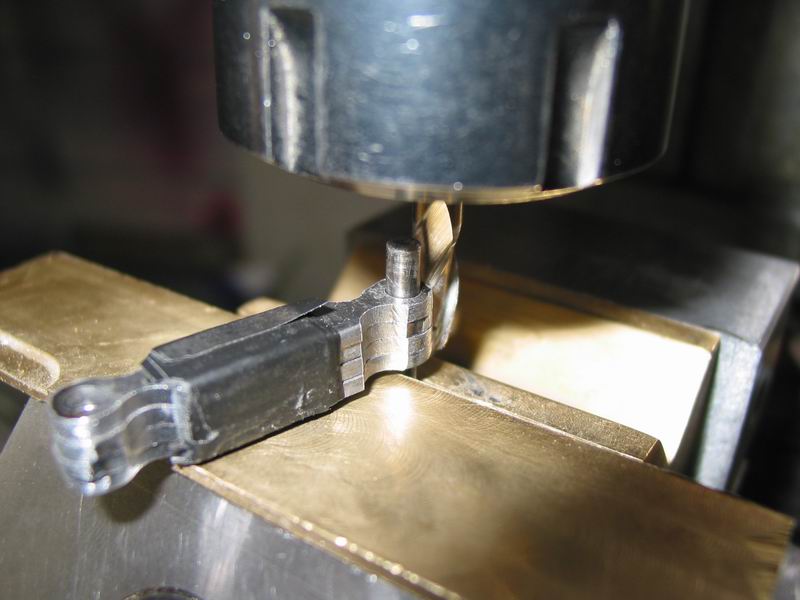

oldboatguys (obg from now) suggested to have these parts realised with lasercut, but I made them with the mill

this is the crankshaft, obg said 'process using laser burned throw plates'... I didn't understand what this means, I made it with lathe and mill from a piece of titanium

I can manage it well with the lathe, but with the mill (X2) is another story!

also the eccentric strap was made of titanium, and was a real pain

another pic of the eccentric

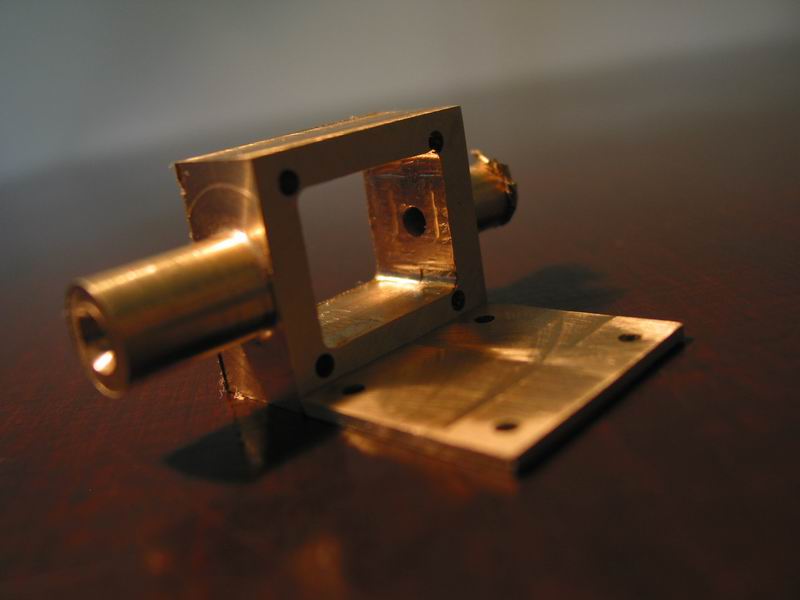

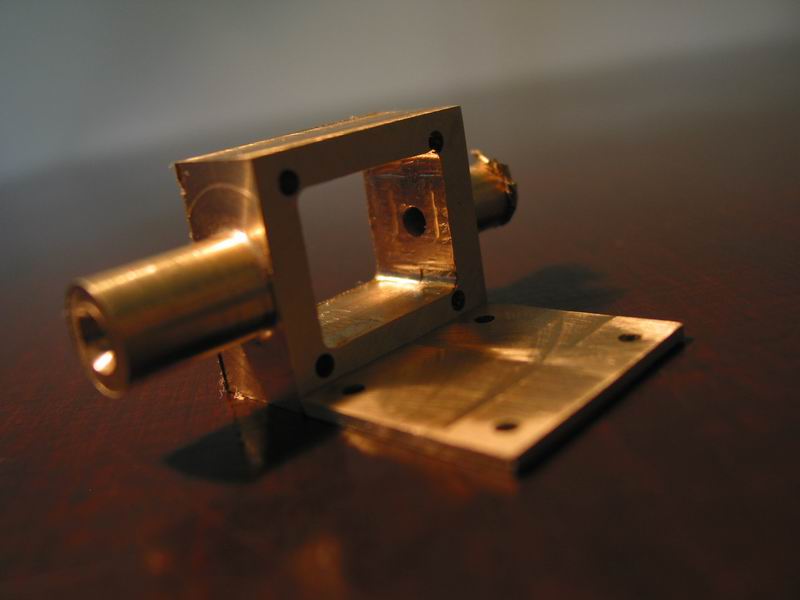

no problems on the cilynder

nor on the steam chest

I'm here for now, they remain many parts to do

but the obg's plans are missing of some parts (in fact there aren't the page n 7 and others), so I have to design the parts that are missing

that's all. if I did something wrong in this post (too many pics?), please let me know

if I did something wrong with the engine, let me know too!!! ;D

thank you

well, I don't know if this is the right section for this post. probably I can't document every step of the work, because I get some photos only by chance, when I remember to do it...

and I have nothing to teach to anybody! I'm new to this hobby, this is my second engine, the first being the steam engine from the brian rupnow plans.

but perhaps sharing this work could be interesting anyway, so here there are the pieces I have done till now

oldboatguys (obg from now) suggested to have these parts realised with lasercut, but I made them with the mill

this is the crankshaft, obg said 'process using laser burned throw plates'... I didn't understand what this means, I made it with lathe and mill from a piece of titanium

I can manage it well with the lathe, but with the mill (X2) is another story!

also the eccentric strap was made of titanium, and was a real pain

another pic of the eccentric

no problems on the cilynder

nor on the steam chest

I'm here for now, they remain many parts to do

but the obg's plans are missing of some parts (in fact there aren't the page n 7 and others), so I have to design the parts that are missing

that's all. if I did something wrong in this post (too many pics?), please let me know

if I did something wrong with the engine, let me know too!!! ;D

thank you