I may very well have out-thought myself with the one way bearing. Although it will work perfectly when driving the carriage into the saw, there is absolutely no good, practical way to disengage it after the log has been fully sawn so that the carriage can be returned to the other end. I may go back to the ratchet and paul, simply because it is so easy to disengage the paul from the ratchet and return the carriage. Due to the small size of the machinery, I can't depend on gravity to do too much. As a consequence, the lever or"paul" which engages the ratchet wheel would have a light tension spring to keep it engaged. By simply swinging the lever away from the ratchet wheel by hand, the carriage can be backed up by hand with no problem. Since there is a very distinct relationship between the stroke of the saw and the advance of the carriage, and the carriage stops but the saw doesn't, I'm not sure how you re-engage the "paul" at the correct notch on the ratchet wheel to maintain this relationship.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model Sawmill Dreaming---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

sorry been long enough it is second nature like scratching the head for most of us.Tin---Try 47 years plus!!!

Tin

I may have just found an excellent source for a steel ratchet wheel. My lathe came with a ton of change gears, none of which I use because I don't use my lathe for threading. The gear are only .280" wide and I seem to have an almost infinite number of different diameters.

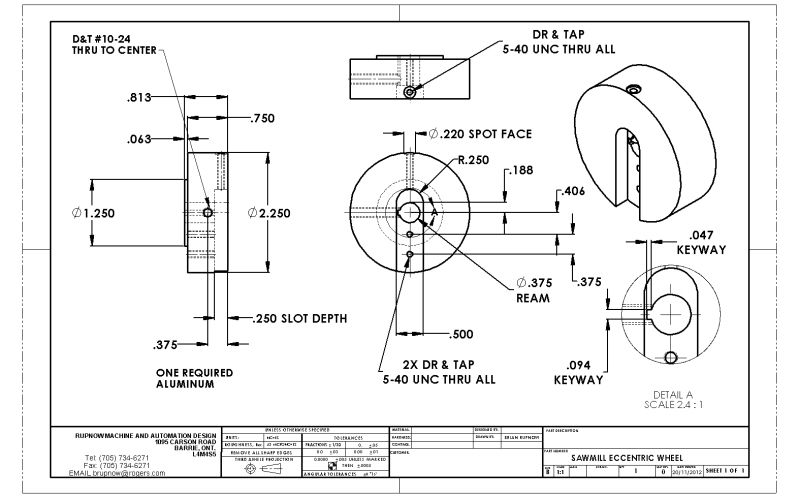

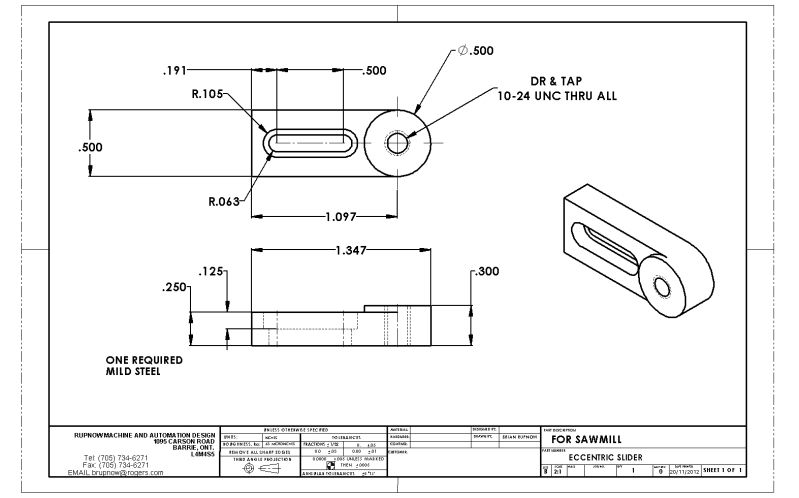

After much thinking about this ratchet and paul/carriage advance business occuring in the correct sequence with the blade stroke-----I've had an epiphany!!! Since the eccentric is on the same shaft as the "crank throw", it will always rotate "in synch" with the blade stroke. Basically, it can't get "out of synchronization" no matter when you choose to engage the paul. It will only advance the carriage when the blade is stroking down. It has no choice. When the blade is stroking up, the eccentric will be lifting the paul away from the rack. So---If I lift the paul from the rack and back the carriage up by hand, it doesn't matter where things are in the rotation of the "crankshaft" which drives the sawblade. It can ONLY advance the carriage when the sawblade is moving downward on its cutting stroke. If I release the paul while the sawblade is on an upstroke, the paul will be retracting. It won't start to move the carriage untill the blade starts to come down. This makes life a lot simpler!!! If I want to back the carriage up fully and pause it there, for instance when the log needs to be repositioned for another cut but the saw is still running, I can have an indent pin to keep the paul disengaged while I do this.

So here we have it with a 4" dia. 100 tooth change gear acting as the ratchet wheel.

Hi Brian,

some links that could be useful. they are in French but with Google translation it's readable.

In France they are called : Scie de Haut fer (something like Overtype Saw).

http://hautfer.pagesperso-orange.fr/images/mecanisme.jpg

http://www.usinages.com/modelisme/recherche-plan-doc-sur-haut-fer-t759-30.html

and the excellent serie of engraving by Armengaud

http://gallica.bnf.fr/Search?ArianeWireIndex=index&p=1&lang=FR&q=armengaud+planches

http://gallica.bnf.fr/ark:/12148/bpt6k61771w/f1.image.r=armengaud planches.langEN

http://gallica.bnf.fr/ark:/12148/bpt6k617727/f1.image.r=armengaud planches.langEN

Enjoy,

Patrick

some links that could be useful. they are in French but with Google translation it's readable.

In France they are called : Scie de Haut fer (something like Overtype Saw).

http://hautfer.pagesperso-orange.fr/images/mecanisme.jpg

http://www.usinages.com/modelisme/recherche-plan-doc-sur-haut-fer-t759-30.html

and the excellent serie of engraving by Armengaud

http://gallica.bnf.fr/Search?ArianeWireIndex=index&p=1&lang=FR&q=armengaud+planches

http://gallica.bnf.fr/ark:/12148/bpt6k61771w/f1.image.r=armengaud planches.langEN

http://gallica.bnf.fr/ark:/12148/bpt6k617727/f1.image.r=armengaud planches.langEN

Enjoy,

Patrick

Thank You METAL89---Some good information there.---Brian

Last edited:

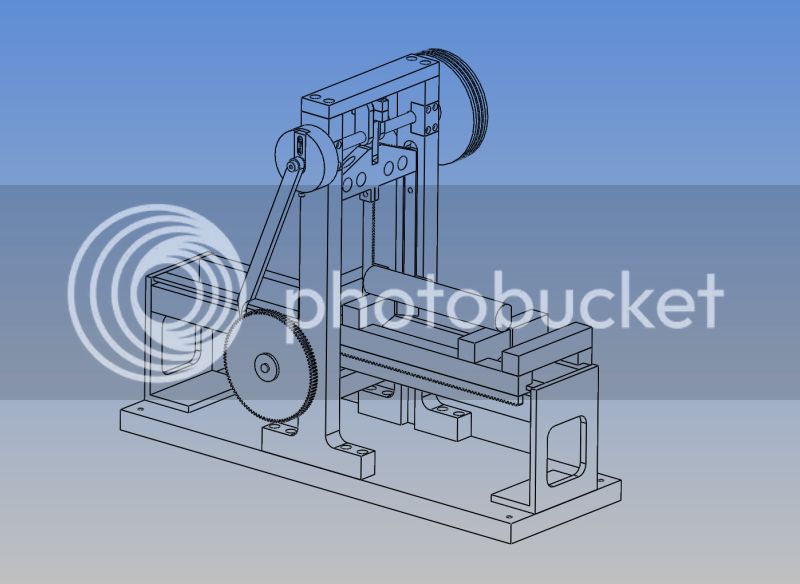

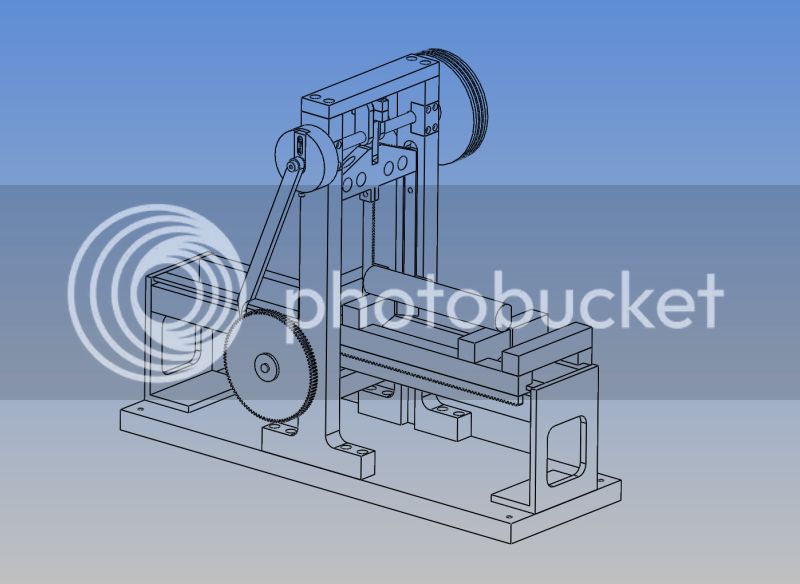

I'm not really sure I want to build this, but Damn, there are just so many neat mechanical motions going on, its hard to resist!!!

No, animations are something that I don't do well nor often.Wow Brian, coming along very nicely.

Will you be animating all the motions in SolidWorks?

John

Well, I guess I'm committed to this project. I just ordered the gear rack (24" long) and 2 spur gears to drive the carriage. I could have made the gears myself, as they are 24 dp., but I can't make the rack with my vertical mill so I figured I might as well buy both gears and rack at one time.There are just too many nifty mechanical things happening with this model to not build it. I'm thinking I will use 3/4 inch square oak for the carriage, dowelled and glued together.

Last edited:

GBritnell---I really like the way you built the lever and ratchet system for "dogging the log over" to cut another board. I haven't really planned anything in that area on mine yet, but if everything else works, I may "borrow" your design and add it to my model.---Brian

"I'm not really sure I want to build this, but"

Sorry Brian mate but there is no way that are you not building this!

I have followed, for the past couple of years, your threads and listened to your commentary on videos and have found them so bl**dy good and to hear your voice is one of the pleasures I take from this site.

I may not of said anything before but, I have followed you.

Please carry on.

Kind regards,

Ron.

Sorry Brian mate but there is no way that are you not building this!

I have followed, for the past couple of years, your threads and listened to your commentary on videos and have found them so bl**dy good and to hear your voice is one of the pleasures I take from this site.

I may not of said anything before but, I have followed you.

Please carry on.

Kind regards,

Ron.

Last edited:

Ronkh---Thanks for the vote of confidence!!! Stick around---I think this will be a fun build.---Brian

starnovice

Member

- Joined

- Nov 21, 2010

- Messages

- 194

- Reaction score

- 23

"I'm not really sure I want to build this, but"

Sorry Brian mate but there is no way that are you not building this!

I have followed, for the past couple of years, your threads and listened to your commentary on videos and have found them so bl**dy good and to hear your voice is one of the pleasures I take from this site.

I may not of said anything before but, I have followed you.

Please carry on.

Kind regards,

Ron.

DITTO

Pat

Similar threads

- Replies

- 61

- Views

- 8K