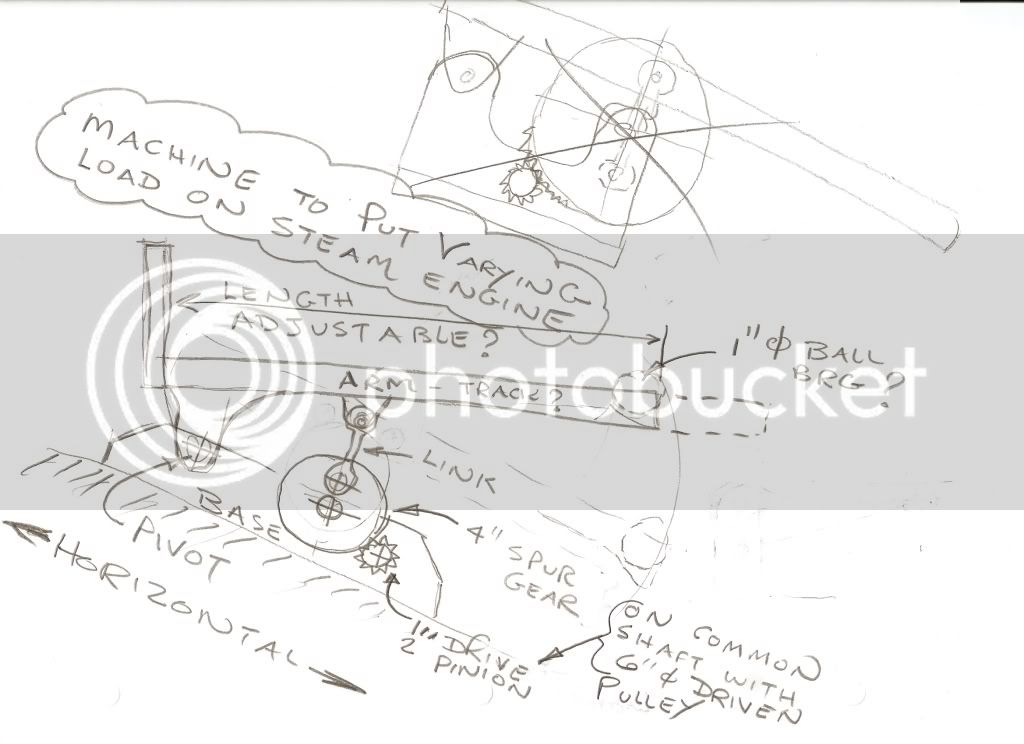

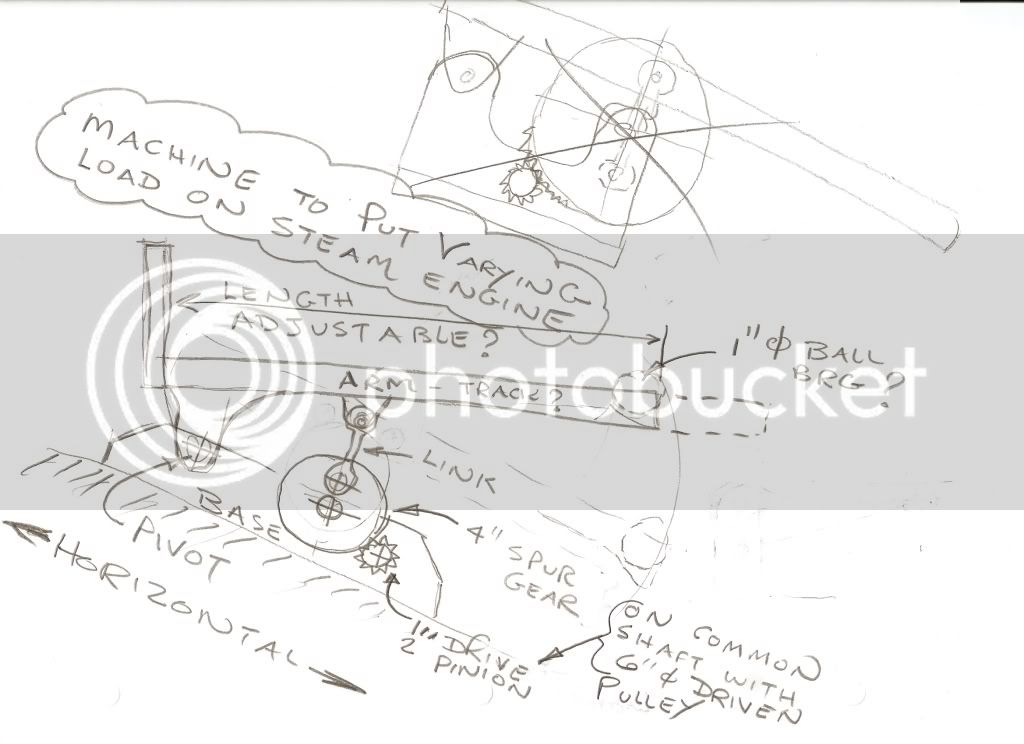

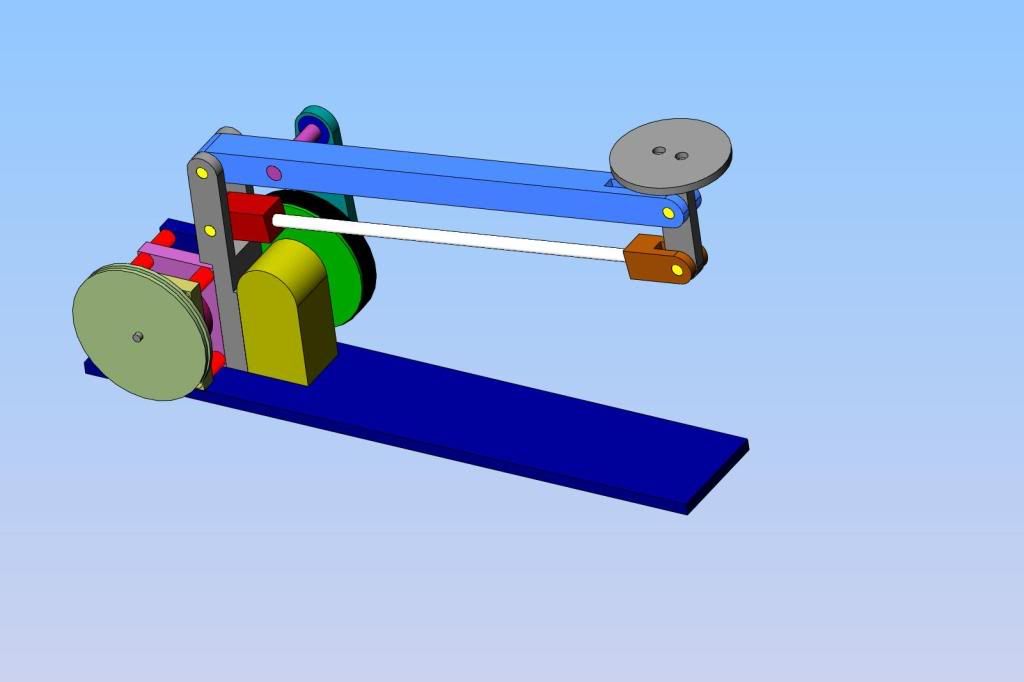

I had originally started this thread in another place, when it was still at the "imagineering" stage, but I have since moved into 'Build it" mode, so have moved over to "A work in progress". What does this machine do, and why did I build it? Well, I wanted my twin horizontal engine with the flyball governor to drive something, which would present a high load on the engine, then a low load, and do it repeatedly, without human intervention, to demonstrate how the governor responds to loads. I plan on exhibiting this machine at steam fairs in my area this coming summer. I have had many good suggestions from folks here on the forum, but most of them involved me doing something to the "device" to vary the load. Since I wanted the machine to do this totally on its own, I designed the following machine. One of the key things that I found is that governors don't respond terribly well to rapidly varying loads, but respond very well to loads that increase and decrease gradually. That is why I have such a massive gear reduction on this device.---Not to increase the torque, but to slow things down so that the load builds and falls in a slow manner. There is a thread currently on the go about planning a project. My projects generally start with a rough sketch, which helps me figure out "How" to achieve a desired result. The attached sketch is my "Rough Sketch".