Hello All;

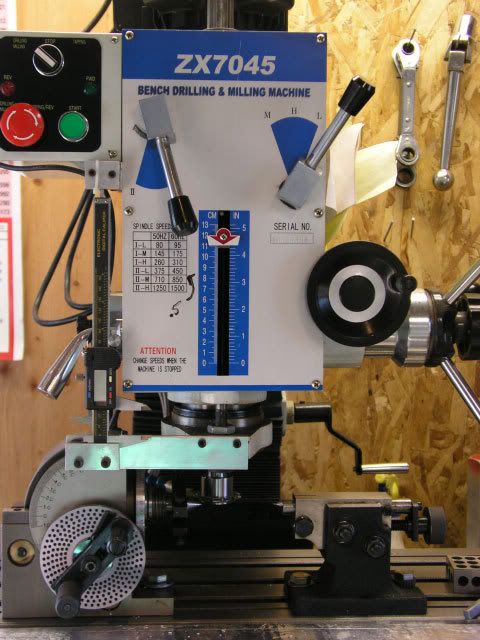

I have just set up a new Zay7045FG/1 Milling machine and have some questions about its operation.

Hopefully some individuals on this site have this machine and can answer some questions.

The first two are:

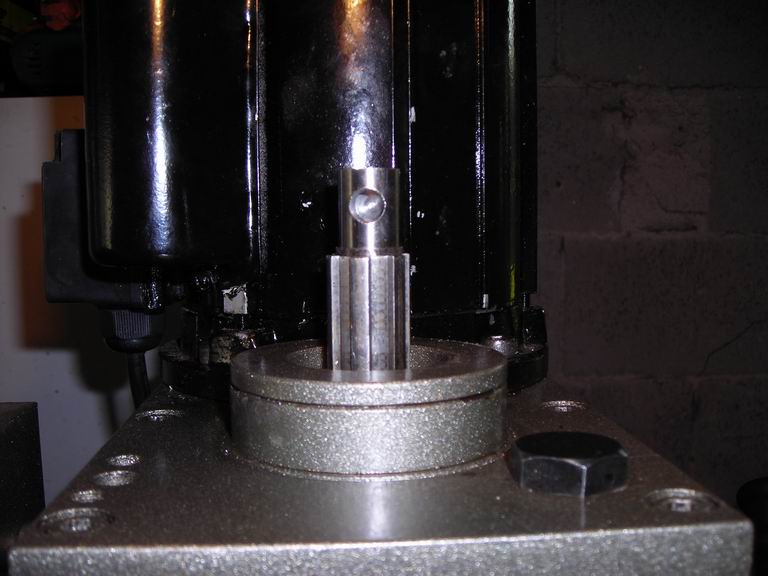

How does one tighten up a R8 collet on the machine as there is no locking lever?

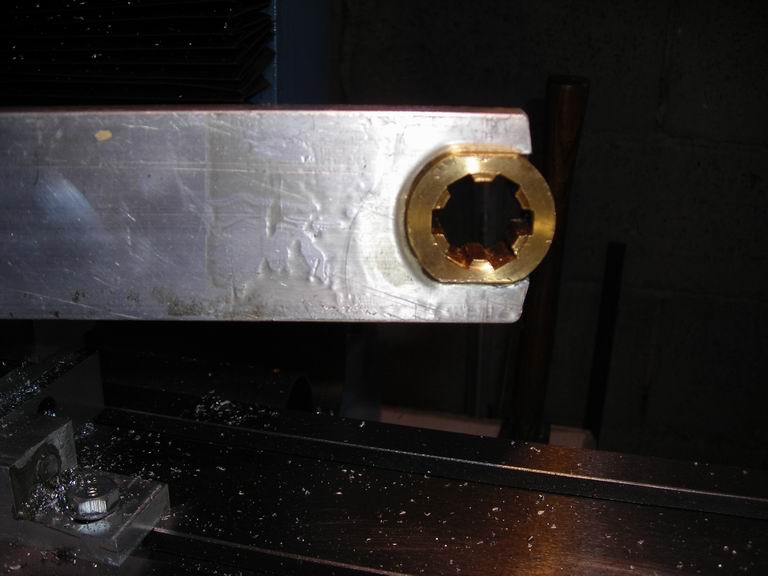

How does one get the machine to run counter clockwise during milling?

Thank you in advance :bow:

Al

I have just set up a new Zay7045FG/1 Milling machine and have some questions about its operation.

Hopefully some individuals on this site have this machine and can answer some questions.

The first two are:

How does one tighten up a R8 collet on the machine as there is no locking lever?

How does one get the machine to run counter clockwise during milling?

Thank you in advance :bow:

Al