jpaul

Well-Known Member

- Joined

- Dec 14, 2007

- Messages

- 70

- Reaction score

- 0

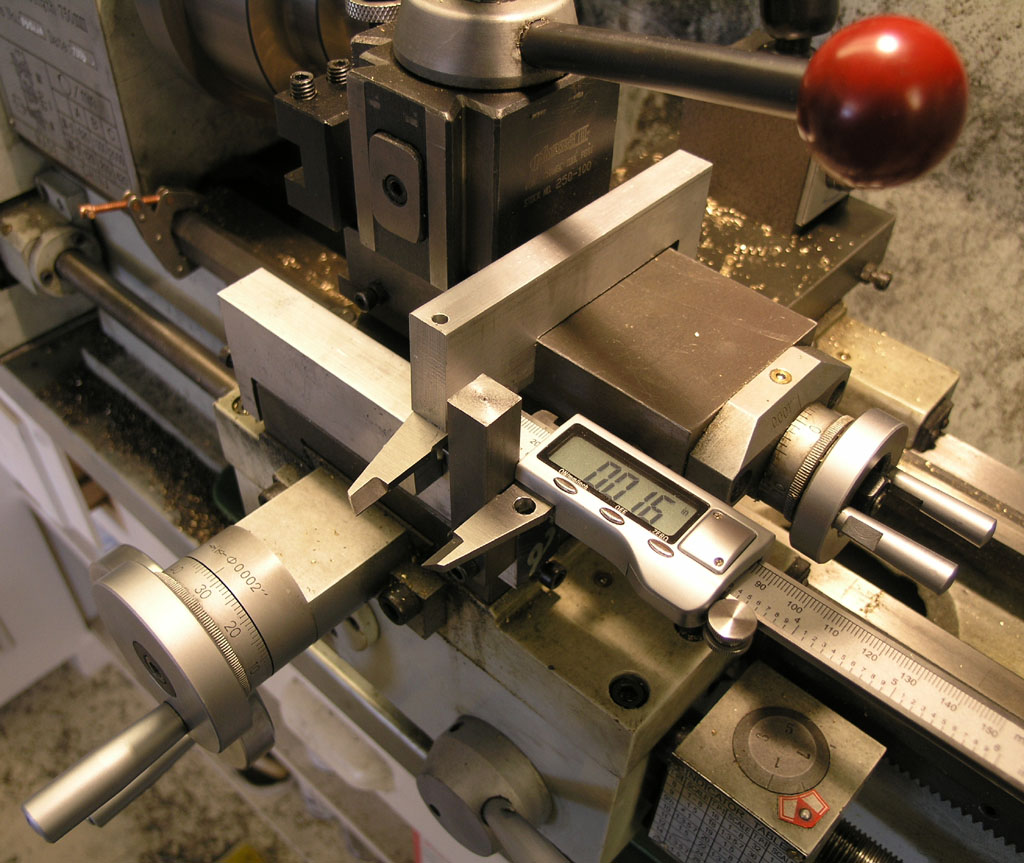

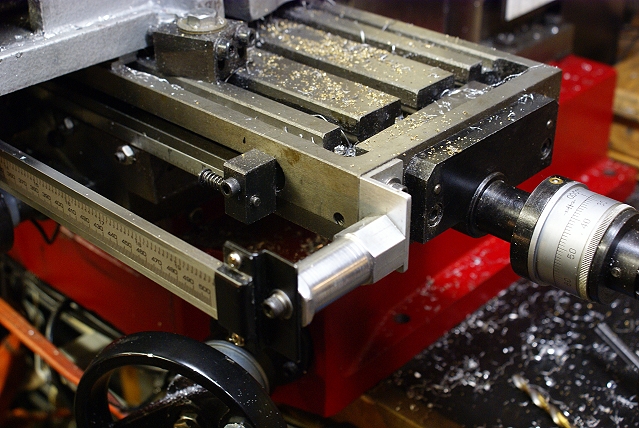

While in the UK I saw several vendors offering linear digital scales. These scales varied in length from 8" to 24" and were available with horizontal or vertical display panels. The price of the scales were approximately $50 US and I got the impression that they were quite popular in the UK. Since returning to California, I have been looking for such an item as well as some conversation on applying these tools to shop set ups.

I am thinking of adapting such a scale to the carriage of my lathe. I would be interested in a "How To" description if available.

So I put this question to the readers. Has anyone adapted one of these linear digital scales to a lathe (or mill) and what was your experience? Are the scales particularly sensitive to cutting oils and swarf?

I am thinking of adapting such a scale to the carriage of my lathe. I would be interested in a "How To" description if available.

So I put this question to the readers. Has anyone adapted one of these linear digital scales to a lathe (or mill) and what was your experience? Are the scales particularly sensitive to cutting oils and swarf?