Hi folks...someone, Thanks a lot anyway, some days ago wrote an URL of laser dealer...I visited the site..and bought two laser unit. One Cross line red laser and a dot red laser. After a dozen of days Items where delivered to my door. I started a project for a shell...but it wasn't so easy....after about two weeks that is the result...Two prototypes this evening finally worked..perfectly... An AutoCAD drawing had been traced...

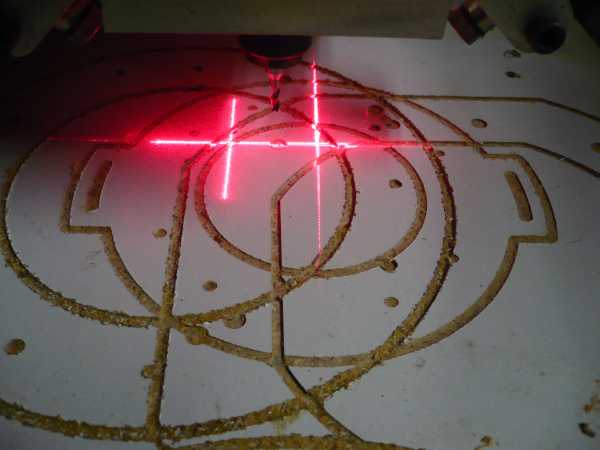

During the adjustment

Working

Very bad news.

The two...

more

During the adjustment

Working

Very bad news.

The two...

more