Hi, I originally had this on model engine maker but the thread didn't really get any traction.

The build is based of Jan Ridder's puppy 2 stroke, most of the design has been modified with the exception of a few parts.

So far:

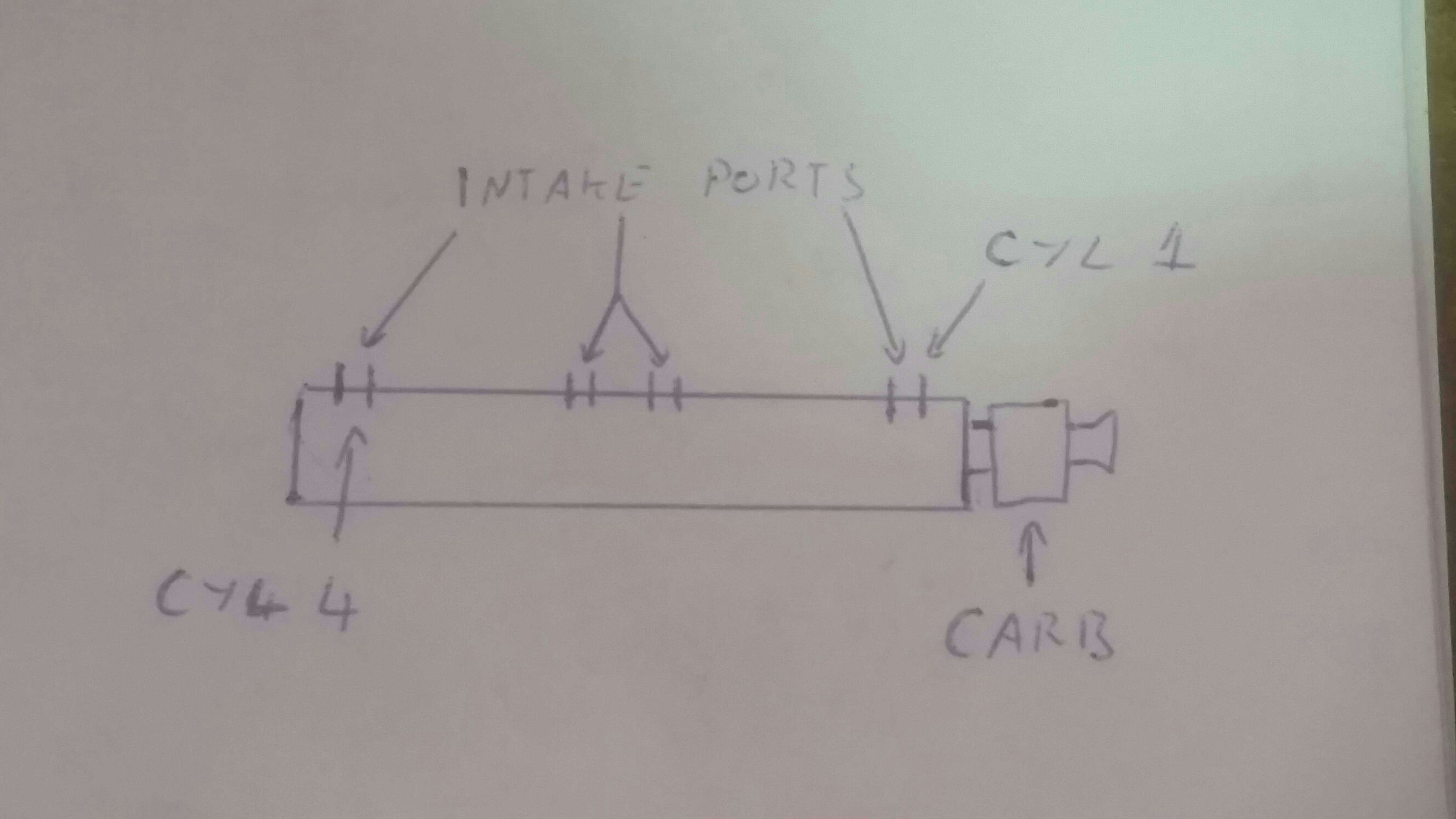

I machined the intake manifold halves at home on my little CNC "mill"

http://youtu.be/pjoD6wnLcmE

The build is based of Jan Ridder's puppy 2 stroke, most of the design has been modified with the exception of a few parts.

So far:

I machined the intake manifold halves at home on my little CNC "mill"

http://youtu.be/pjoD6wnLcmE