KenErickson

Junior Member

- Joined

- Dec 24, 2012

- Messages

- 18

- Reaction score

- 13

I just recently joined, introduced myself to your wonderful forum and thought I would try and contribute for my first real post.

I did a search and only found one other post on the subject so I hope this helps out a bit.

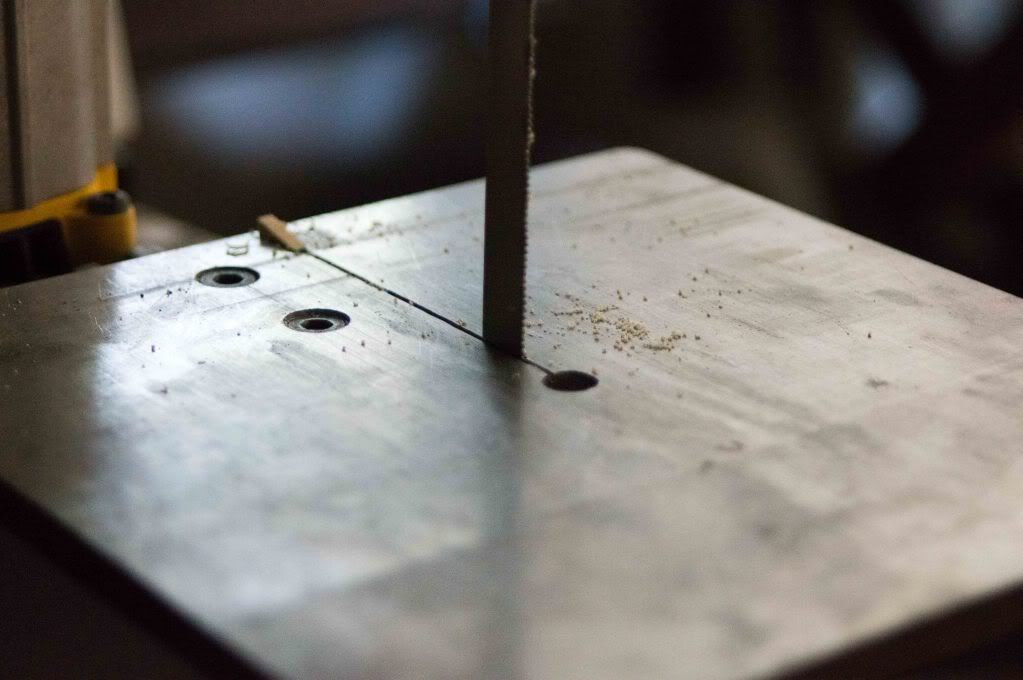

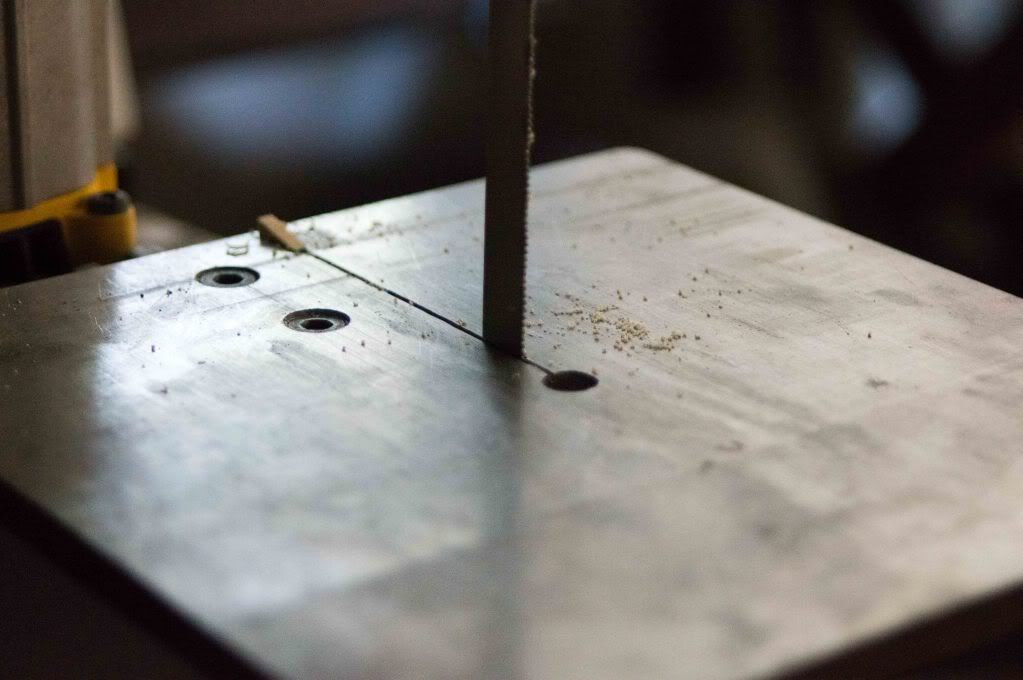

I profile a lot of stainless/high carbon stock from flat stock that is normally less than .200 and needed a space saving and inexpensive vertical band saw. This saw could be used to profile many parts intended for small engines also .

.

Many companies make porta-band metal cutting saws. I used a Dewalt and removed the handle and simply set it between a length of steel channel (in this case, c-clamped) to my workbench legs. I then made a heavy steel platten to replace the small sheet metal rests that these saws are shipped with. While not a full featured vertical bandsaw I find this is an economical and space saving solution that has worked well for me.

I did a search and only found one other post on the subject so I hope this helps out a bit.

I profile a lot of stainless/high carbon stock from flat stock that is normally less than .200 and needed a space saving and inexpensive vertical band saw. This saw could be used to profile many parts intended for small engines also

Many companies make porta-band metal cutting saws. I used a Dewalt and removed the handle and simply set it between a length of steel channel (in this case, c-clamped) to my workbench legs. I then made a heavy steel platten to replace the small sheet metal rests that these saws are shipped with. While not a full featured vertical bandsaw I find this is an economical and space saving solution that has worked well for me.

Last edited: