PeterB

Well-Known Member

- Joined

- Mar 2, 2012

- Messages

- 53

- Reaction score

- 14

I´ve got a hand reamer but I'm not sure how to use it. I'm going to make a cylinder and I have used my lathe to make a hole that I now want to ream.

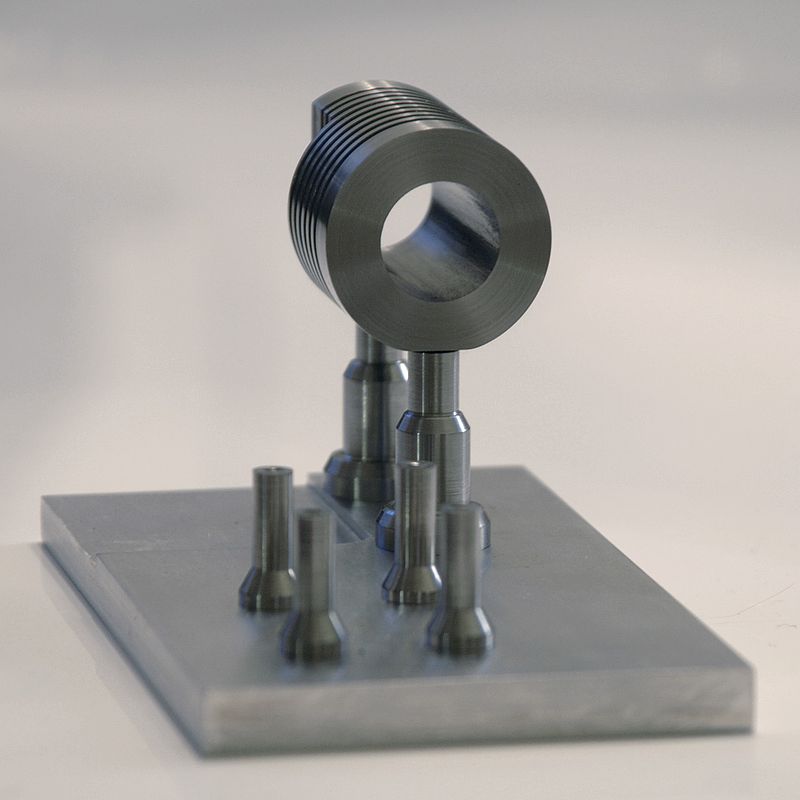

Can anyone explain to me how I should do for best result. The reamer is the one in the pic.

Can anyone explain to me how I should do for best result. The reamer is the one in the pic.