OK! I'm trying mt best to follow Brian's plans and pictures of the build described here:

http://www.homemodelenginemachinist.com/index.php?topic=5234.0

I've been doing pretty well (the plans are great!!) however, there seems to be an epiphany between reply #13 and reply #14 of the above. ;D

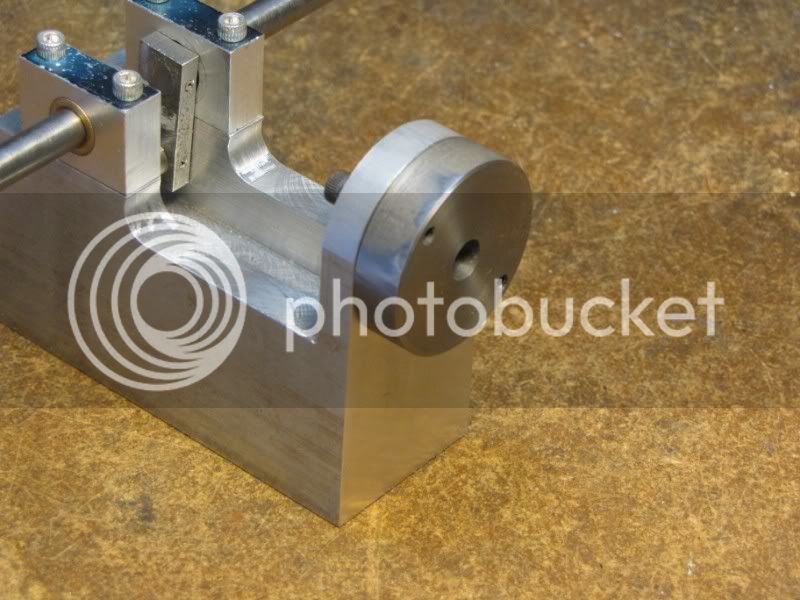

I understand the boring of the hole in the crankcase for the cylinder, but I can't for the life of me figure out how to create the .625 radius that suddenly appears in reply #14. (around the upper half of the cylinder hole.)

Surely it's not done freehand with a file.

Also, are there any specs for the slider valve in the cylinder head? (Or did I miss something in the plans?)

Thanks,

Dean (And I just discovered what was meant by "If your rich, you can use brass" :hDe:

http://www.homemodelenginemachinist.com/index.php?topic=5234.0

I've been doing pretty well (the plans are great!!) however, there seems to be an epiphany between reply #13 and reply #14 of the above. ;D

I understand the boring of the hole in the crankcase for the cylinder, but I can't for the life of me figure out how to create the .625 radius that suddenly appears in reply #14. (around the upper half of the cylinder hole.)

Surely it's not done freehand with a file.

Also, are there any specs for the slider valve in the cylinder head? (Or did I miss something in the plans?)

Thanks,

Dean (And I just discovered what was meant by "If your rich, you can use brass" :hDe: