I can just tell that if all the guys on this forum lived within 25 miles of Barrie, they`d all be over in my shop helping to get this engine hitting and missing properly. Everyone is giving great suggestions, and honest, I have tried them all. I have tried heavier flywheels, I have tried lighter flywheels, I have tried one flywheel, I have changed the valve timing so many times that I had to put new socket head setscrews in the crankshaft gear because the wrench hole edges rounded out on the original set screws. I have tried heavier governor weights, I have tried lighter governor weights, I have tried at least 50 advanced and retarded positions on the ignition timing, I have put in ball bearings with their seals removed to support the crankshaft, I have made a new cam exactly to Kerzel`s original plans, I have made a new crankshaft. I have moved the flywheel with the governor weights closer to the engine, I have moved it farther from the engine (this affects the hysteresis--the gap between the Kerzel lever and the catch on the push-rod assembly). I have put a lighter spring on the atmospheric intake valve, I have put a new viton ring on the piston just in case the 6 year old ring was worn out. I have set the valve lash a number of times. The only thing I haven`t tried is running my engine in the opposite rotation (which is exactly what the one in the video by Dick from Ohio is doing) and I may yet try that.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Heavier flywheels for the Kerzel hit and miss engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The only thing I haven`t tried is running my engine in the opposite rotation (which is exactly what the one in the video by Dick from Ohio is doing) and I may yet try that.

Interesting observation!

You may also note that the video you linked to in post #3 is also running in that rotation.

Also, another video I found, which I think could probably be the best runner yet, rotates the same way:

[ame]https://www.youtube.com/watch?v=F_GUp5UXmxE&feature=youtu.be[/ame]

This one was built by HMEM member 'Weez'

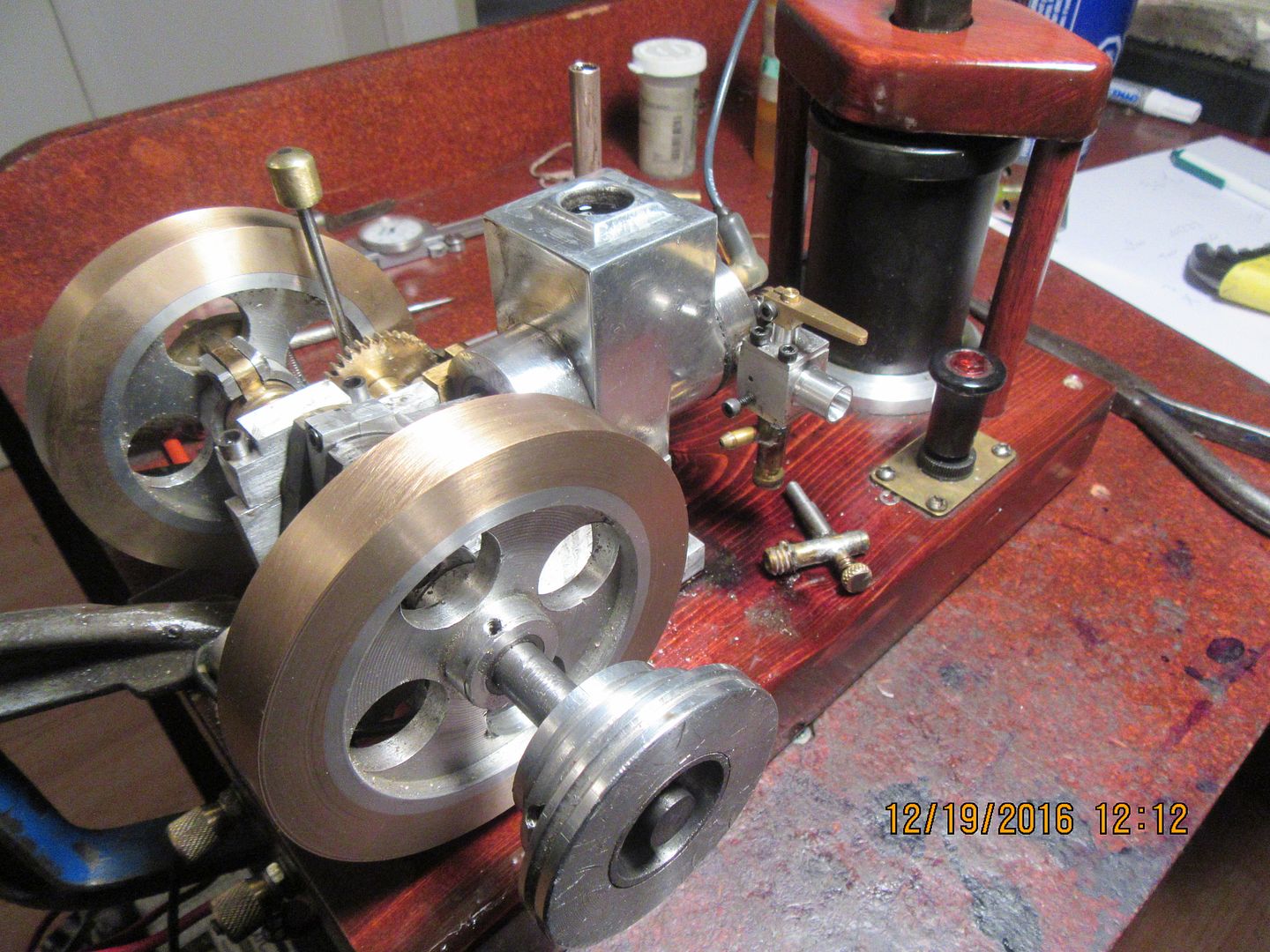

So, after two weeks or more of screwing around with this engine, it seems I am back to about where I started. Excuse the oil splatters--that is actually WD40 sprayed on while running, hoping to free up anything which may have been in the least bit "sticky". The only trick I have left is to try setting the engine up to run in reverse rotation. I have no idea why that would make any difference, but in an effort to "leave no stone unturned" I will probably try that next.

[ame]https://www.youtube.com/watch?v=7PsXe6_P5yo&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=7PsXe6_P5yo&feature=youtu.be[/ame]

- Joined

- Jul 16, 2007

- Messages

- 2,985

- Reaction score

- 1,051

Brian,

In watching your last video if I had to guess what is going on I would say that your governor springs are too strong. The governor weights pop out just when the engine hits and on the next stroke or two they retract.

Just my two cents worth.

gbritnell

In watching your last video if I had to guess what is going on I would say that your governor springs are too strong. The governor weights pop out just when the engine hits and on the next stroke or two they retract.

Just my two cents worth.

gbritnell

You could be right George. I tried it with only one spring and it ran so slowly it would hardly keep going. I then shortened the one spring and it still ran very, very slowly. then I put the two springs back on.Brian,

In watching your last video if I had to guess what is going on I would say that your governor springs are too strong. The governor weights pop out just when the engine hits and on the next stroke or two they retract.

Just my two cents worth.

gbritnell

Cogsy

Well-Known Member

Brian - I was just out whippersnipping (weedeating I think you guys call it?) the jungle in the backyard as the dog was getting lost and the kangaroos were sneaking up and pinching the chook food, and I found myself thinking about your Kerzel. I seem to remember a video not so long ago (I think when you first got it out after not running for a long time) and if I remember correctly you had to fiddle with the fuel mixture a couple of times in about 1 minute to keep it going into hit and miss. I know these little carbs can be finicky but I'm thinking this one might be playing up. Especially if it runs really slowly with light governor springs - if it was getting a nice big hit it would spin the flywheels nice and fast then the light springs would keep it from hitting again til it had slowed right down. If you're only getting a small change in flywheel velocity it has to mean low power (I've almost convinced myself).

You've tried valve and ignition timing and compression is good (I think you said) so I'd suggest trying it with a known good carb from a similar sized engine to see if you can get more Oompf from each hit.

You've tried valve and ignition timing and compression is good (I think you said) so I'd suggest trying it with a known good carb from a similar sized engine to see if you can get more Oompf from each hit.

I do have one of my fabulous "Jag" carburetors here, which has a thru bore of 0.195" as compared to the .125" passage thru the existing Upshur carb currently on the engine, which has a thru bore of 0.125". That is an increase of 243% in cross sectional area. The threads on the jag carb are the same as the threads on the Upshur style carb. It won't cost me any money to switch out the carburetors, just a bit of time. If I can pump twice as much fuel/air mix into the combustion chamber I don't know what the net effect will be. The engine has an atmospheric intake valve and no forced air induction, so maybe nothing will change.--But then again-----

If I hold a valve open and flip the flywheel with my hand I get 2 full rotations of crankshaft, maximum.Hey Brian,

do you think the o-ring is making to much drag? If you hold the exhaust valve open and give the flywheels a spin with your hand does it make a couple revolutions, or does it lose it's momentum fast?

Jonathan

If I hold a valve open and flip the flywheel with my hand I get 2 full rotations of crankshaft, maximum.

Two full rotations that doesn't seem like a lot to me. That could be where the problem is, if the friction is lower it would free wheel longer. Which would mean that the miss part would take longer to slow down to go back into hit mode. Is there anything you can do to free up some friction to see if that would help?

In short---No, not really. It has ball bearings instead of bushings already.Two full rotations that doesn't seem like a lot to me. That could be where the problem is, if the friction is lower it would free wheel longer. Which would mean that the miss part would take longer to slow down to go back into hit mode. Is there anything you can do to free up some friction to see if that would help?

What about replacing your o-ring with Teflon tape, the same stuff pipe fitters use on threaded connections. Just take a couple inches and spin it into a rope. It should glide smooth in the bore. It might give you a chance to reduce some friction with out doing a lot of work to it. Even if the Teflon only holds up for 10 mins.

Tonight I had the Kerzel running quite elegantly with the larger carburetor on it, and the Kerzel lever removed. I was afraid that the carburetor might be too large for a 3/4" diameter single cylinder engine. As the barrel of the carburetor gets larger, the air flowing thru it slows down, and consequently doesn't create as much of a low pressure area (Venturi effect) in the area where the spray bar for the gasoline pokes into the air stream. Since the low pressure area becomes less, it won't lift gasoline from the tank nearly as well, and the engine starves for fuel. It is very cold outside, and I don't want to gas myself, so I didn't have the engine running for very long. It does seem to be working all right with the larger carb, and is responsive to the opening/closing of the throttle. I will do more testing as time allows, out in my main garage. Once I am convinced that the engine is okay with this larger carb, I will try out the hit and miss function again.

An interesting factoid--I just went back and had a look at the original Kerzel carburetor plans. Kerzel calls for a 3/16" thru hole in the carburetor with a 1/4" counterbore from both ends. For whatever reason, at the time I was unable to make this carburetor, but was able to make a carb from an old set of Upshur plans that I found on an internet site. The Upshur carburetor must have had a 1/8" thru hole because that is what I have measured on the carb I just replaced on the engine. I have always thought that my engine didn't hit as strongly as other Kerzel engines I have seen videos of on the net. It seems that the bore of my Jag carburetor is much closer to what Kerzel originally intended.

Awright!!--We're done here!! Not exactly what I was hoping for, but close enough for me. It does hit, it does miss, and it starts easy.

[ame]https://www.youtube.com/watch?v=swoSgioWTO8&feature=youtu.be[/ame]

[ame]https://www.youtube.com/watch?v=swoSgioWTO8&feature=youtu.be[/ame]

- Joined

- Oct 1, 2010

- Messages

- 1,342

- Reaction score

- 395

Brian,

I knew you'd get it licked. I like the way it runs and sounds now.

It looks nice, too.

Not many of us like to revisit past projects after passage of time, no matter what we promise: You get the perseverence award for this one.

Gotta get me my ration of Rupnow postings to complete my day.

Thanks

--ShopShoe

I knew you'd get it licked. I like the way it runs and sounds now.

It looks nice, too.

Not many of us like to revisit past projects after passage of time, no matter what we promise: You get the perseverence award for this one.

Gotta get me my ration of Rupnow postings to complete my day.

Thanks

--ShopShoe

Thank you Shopshoe. Other than what I can find on the internet, I live in kind of a vacuum here, as far as model engines go. I have very little to compare my stuff to after I have built it.--Brian

Jyman--I got the engine up and running 6 years ago, as can be seen in post #2 of this thread. All of the things I did over the last month was aimed at possibly getting a better hit and miss action. If you watch the very last video and then watch the video in post # 2, there really isn't a heck of a lot of difference.---Brian

Similar threads

- Replies

- 5

- Views

- 2K

- Replies

- 19

- Views

- 5K