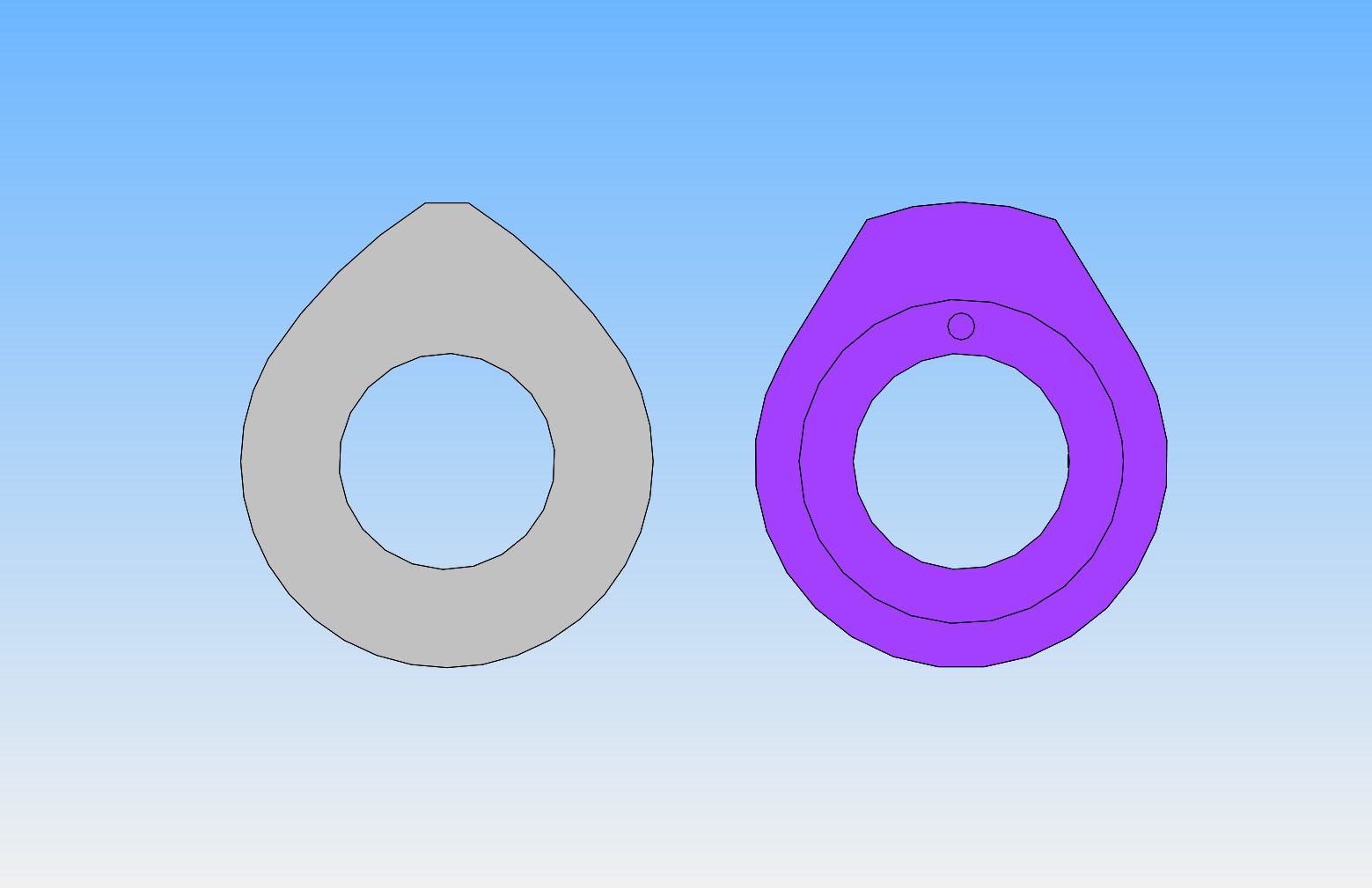

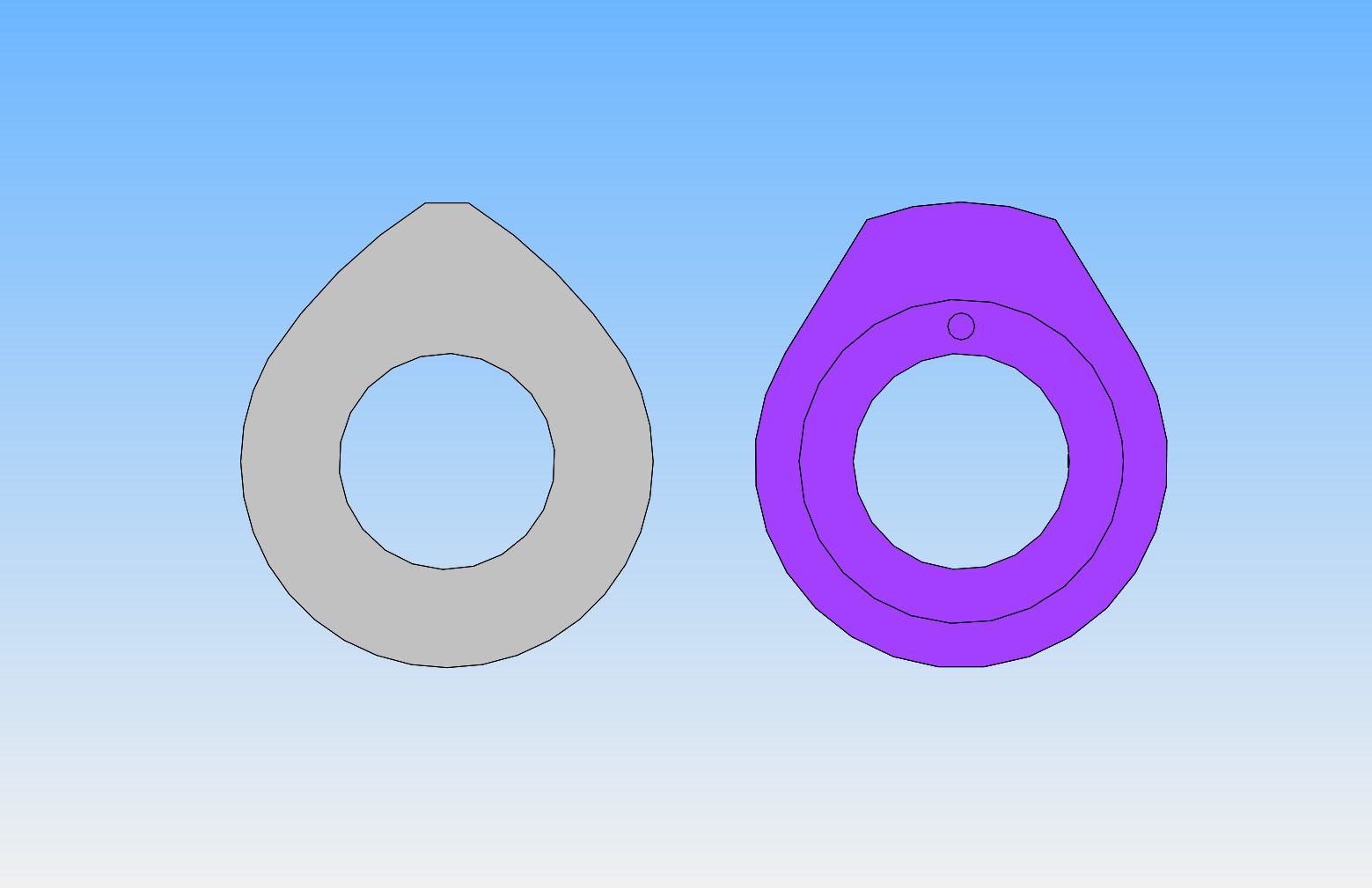

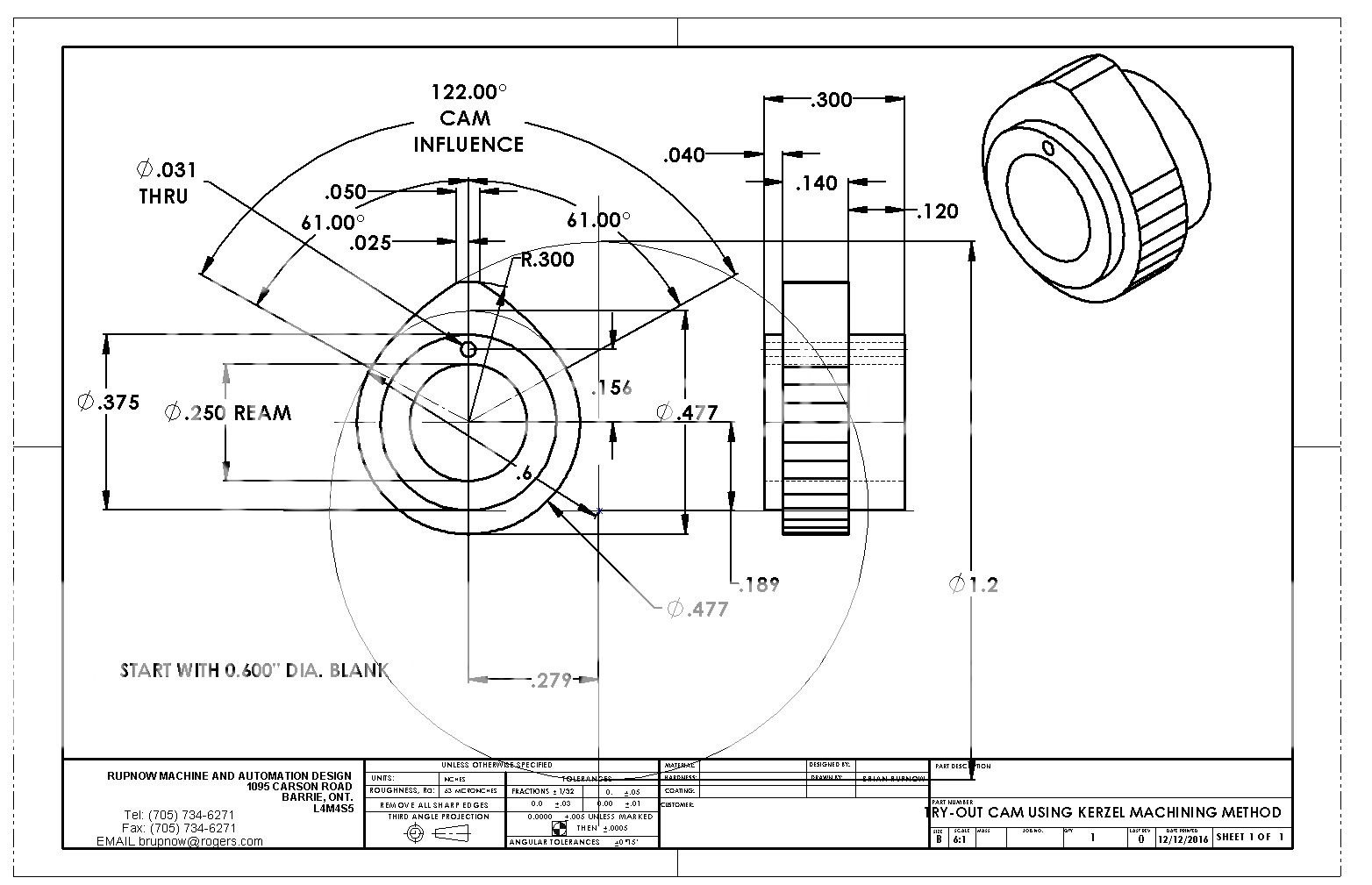

Before I go any farther with modifications to this engine, I have to right an old wrong. When I first built this engine 6 years ago, I had only built one engine before it, the Webster. I had a terrible time getting this engine to run at all, and finally, in a rather desperate move, decided that the cam design per Mr. Kerzel must be wrong. So---since I had great experience with the Webster, I decided to make a clone of the Webster cam to run in the Kerzel engine. As you can see from the attached picture, the grey cam (as per Mr. Kerzel) and the blue cam (as a clone of the Webster cam) are very different. Since I am head and shoulders back into this engine, I will make a new cam according to Kerzel's original plan and install it. The dwell on the blue cam, which I am currently running, is about 4 times greater than the cam designed by Kerzel. This has to be having a pretty radical effect on the engines performance, so I will make a new cam and install it before I do anything else.