Generatorgus

Senior Member

- Joined

- Feb 25, 2010

- Messages

- 362

- Reaction score

- 166

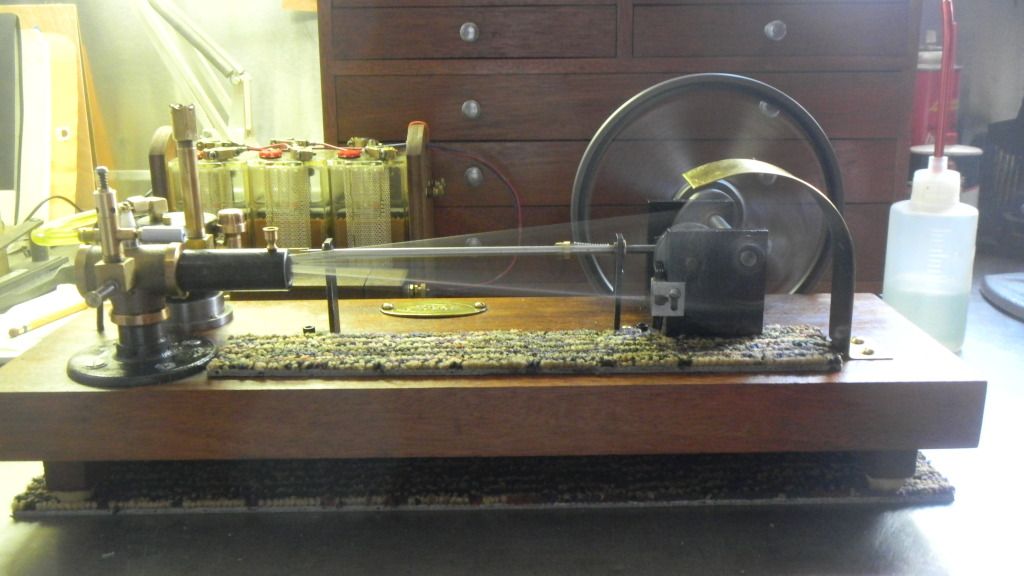

About 4 years ago I was inspired to try my hand at building the Henry Ford engine, my first try at an IC engine.

Pretty simple looking, ought to be a breeze., I thought. I had some years of static model making and later little running electric engine models.

As it turns out, this simple engine taxed my abilities and patience to an all time high.

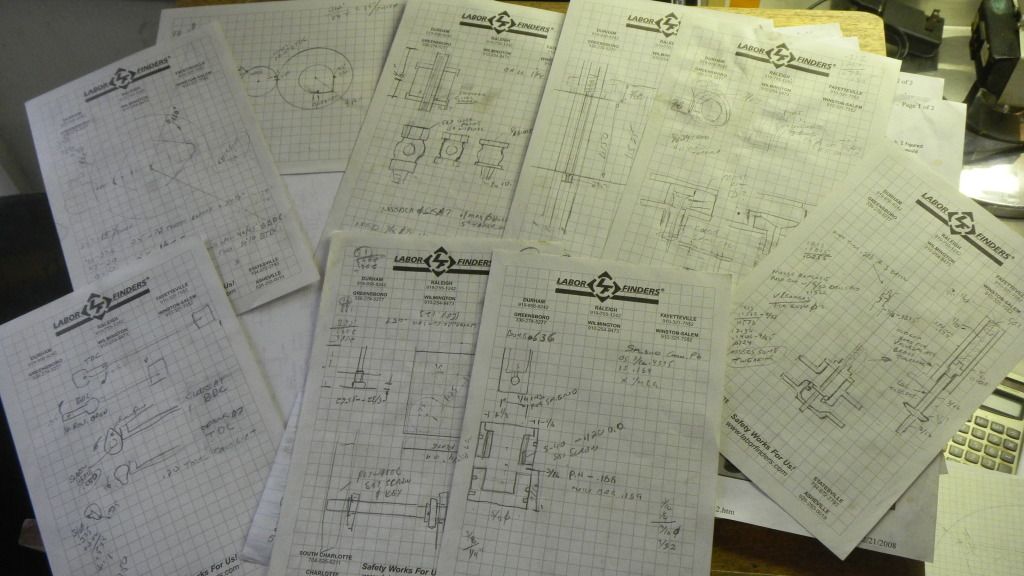

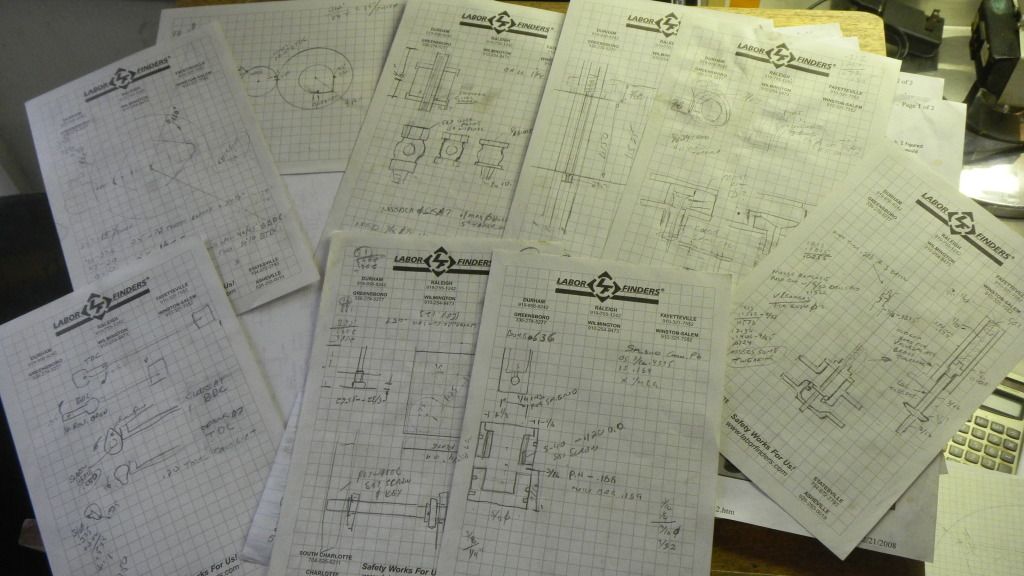

No plans, I just , kind of scaled it down from some photographs, using a combination of what I scaled, what would make convenient dimensions, and what would work with the hardware and useable components.

That was the easy part. No overall plan, I gathered materials and just made sketches as I built.

As time and work progressed over about a years time, there were many failures and disappointments.

I'm not too embarassed to say I acually took a hammer to one of these.

I finally got this early version built and managed to get it running, although not too well and not too long, either.

The project came to a halt. Bad compression and a bad flooding problem. I didnt have the skills or knowlege at the time to get it running right and also didnt know how to overcome the flooding problem.

That next summer I bought a Breish, Little Brother kit, from the widow of friend.

Next thing I know Im building another engine. Why I would think this one would run, I dont know. But that story had a very happy ending.

I had been watching this site from the closet for a while and with that help and personal tutelage of an experienced model maker, a member of this forum, I wont mention his name because I dont want to make him blush from the compliment. Lets just say, I owe ya buddy.

At any rate armed with my new wealth of knowledge, I plunged back into my failed project and finally came up with this jury rigged, but running damned good (in my own over inflated opinion), version.

Actually, I laughed out loud when it first started.

Pretty simple looking, ought to be a breeze., I thought. I had some years of static model making and later little running electric engine models.

As it turns out, this simple engine taxed my abilities and patience to an all time high.

No plans, I just , kind of scaled it down from some photographs, using a combination of what I scaled, what would make convenient dimensions, and what would work with the hardware and useable components.

That was the easy part. No overall plan, I gathered materials and just made sketches as I built.

As time and work progressed over about a years time, there were many failures and disappointments.

I'm not too embarassed to say I acually took a hammer to one of these.

I finally got this early version built and managed to get it running, although not too well and not too long, either.

The project came to a halt. Bad compression and a bad flooding problem. I didnt have the skills or knowlege at the time to get it running right and also didnt know how to overcome the flooding problem.

That next summer I bought a Breish, Little Brother kit, from the widow of friend.

Next thing I know Im building another engine. Why I would think this one would run, I dont know. But that story had a very happy ending.

I had been watching this site from the closet for a while and with that help and personal tutelage of an experienced model maker, a member of this forum, I wont mention his name because I dont want to make him blush from the compliment. Lets just say, I owe ya buddy.

At any rate armed with my new wealth of knowledge, I plunged back into my failed project and finally came up with this jury rigged, but running damned good (in my own over inflated opinion), version.

Actually, I laughed out loud when it first started.