- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

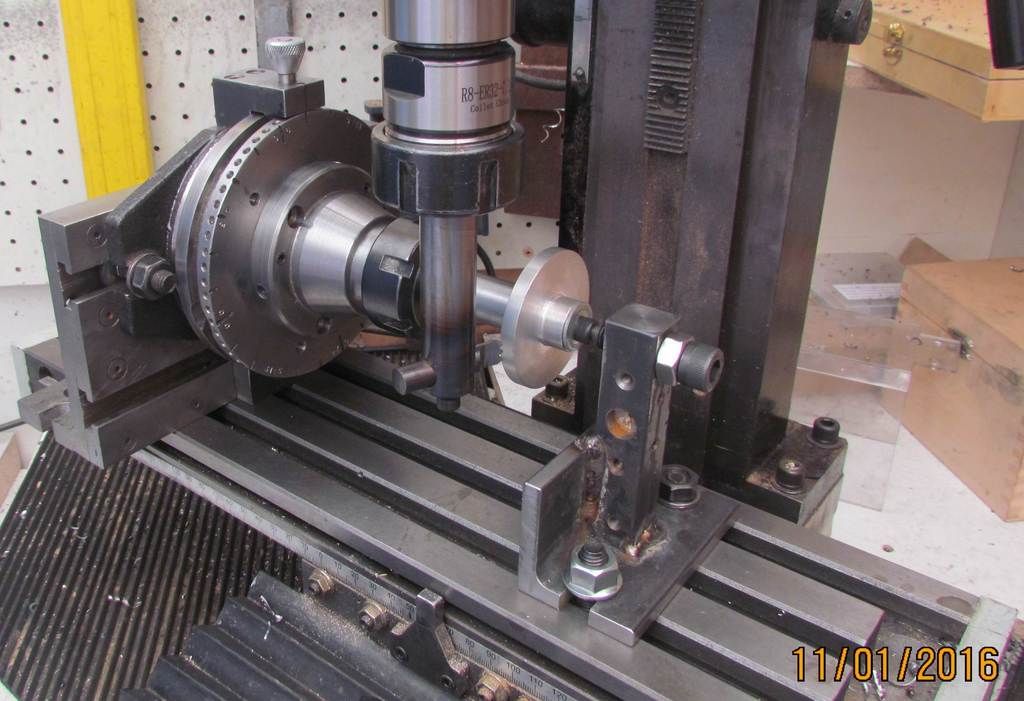

I am almost ready to cut the 2 gears for the V8 but need to make

a few items first so have opened this thread for the prep work

I need to make

1- cutting tool

2- support mandrel

3- Tailstock support centre for the mill

4- deviding plate for 52 increments

When these items are finished i will return to the original thread for cutting the gears

a few items first so have opened this thread for the prep work

I need to make

1- cutting tool

2- support mandrel

3- Tailstock support centre for the mill

4- deviding plate for 52 increments

When these items are finished i will return to the original thread for cutting the gears