Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

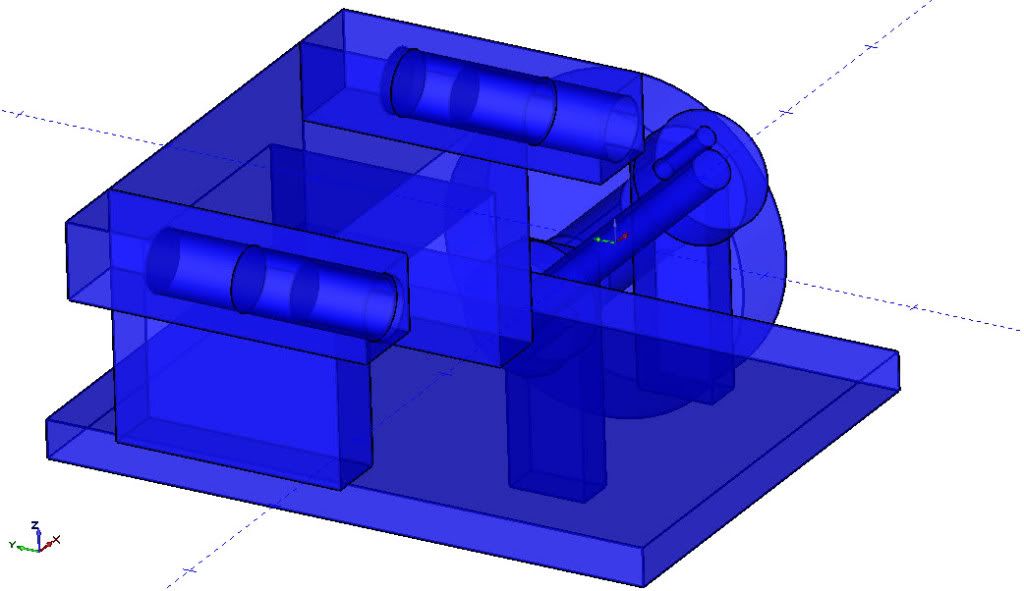

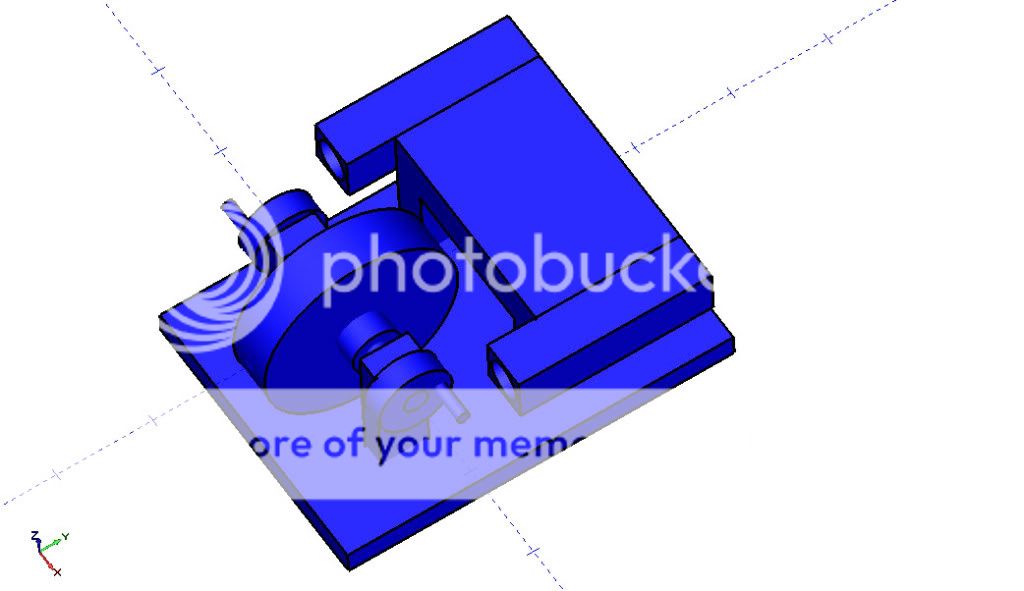

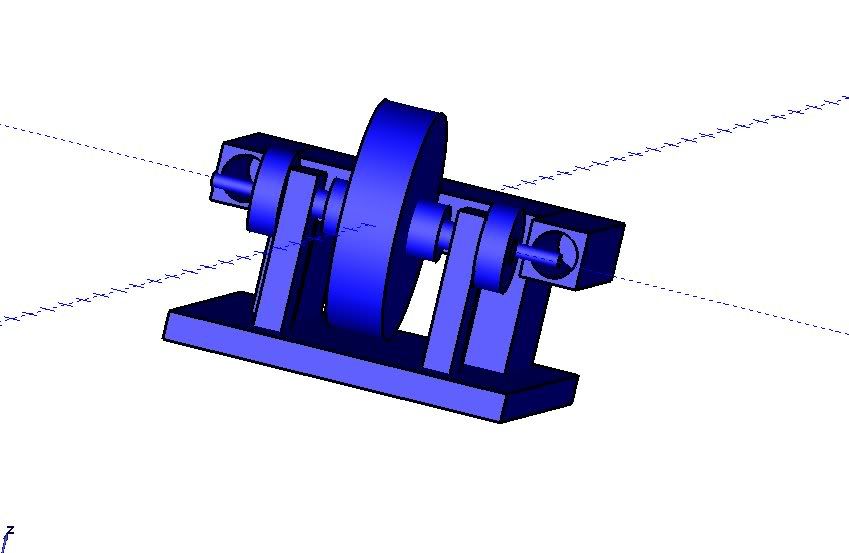

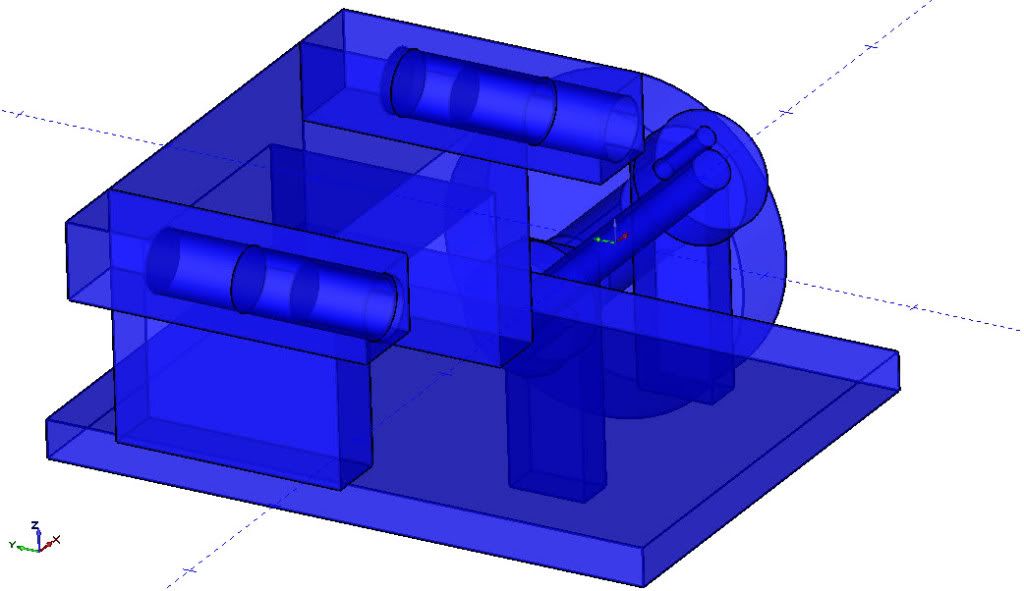

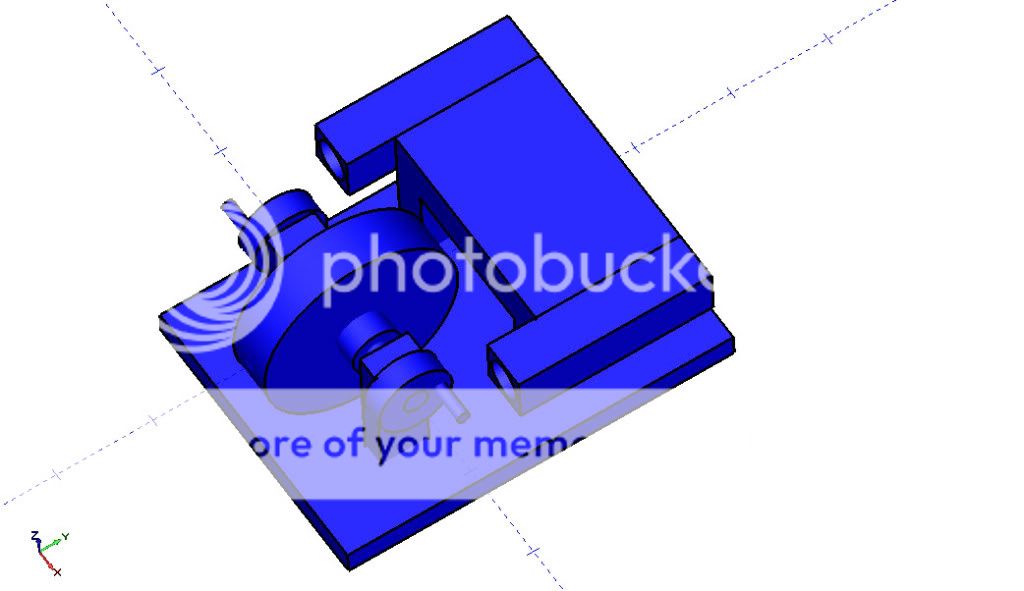

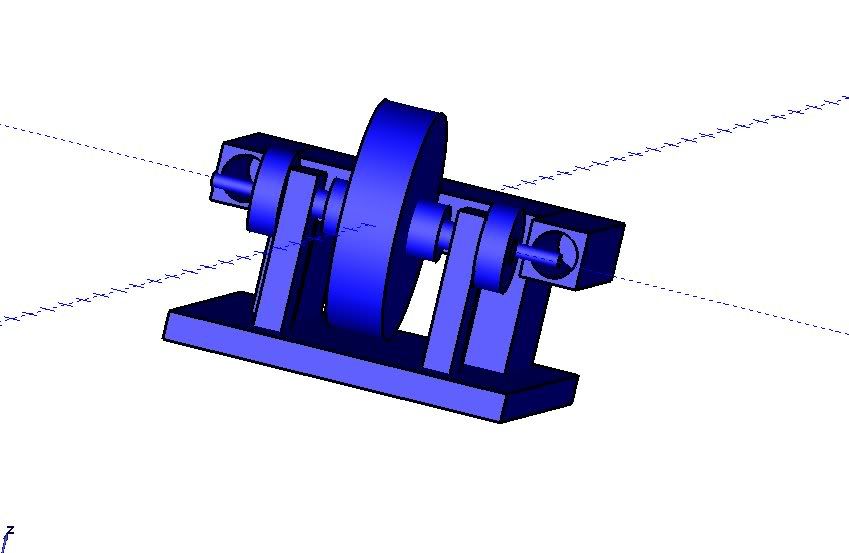

Well in for a pound as they say.....after building the two wobbler's I started to think about an engine on the same principles but with two cylinders so it would self start (one hopes......(posh now I am using a computer)). I also am learning how to use BobCad Cad program.

So to recap, I am a novice engineer, a novice Cad user and a novice designer. Should be an interesting ride!

Anyway copyright accepted as the design will be worth a fortune...so its free if it works and for sale if it doesn't...Have I got that right? Anyway a few images to show where I am. Advice and constructive criticism welcome.

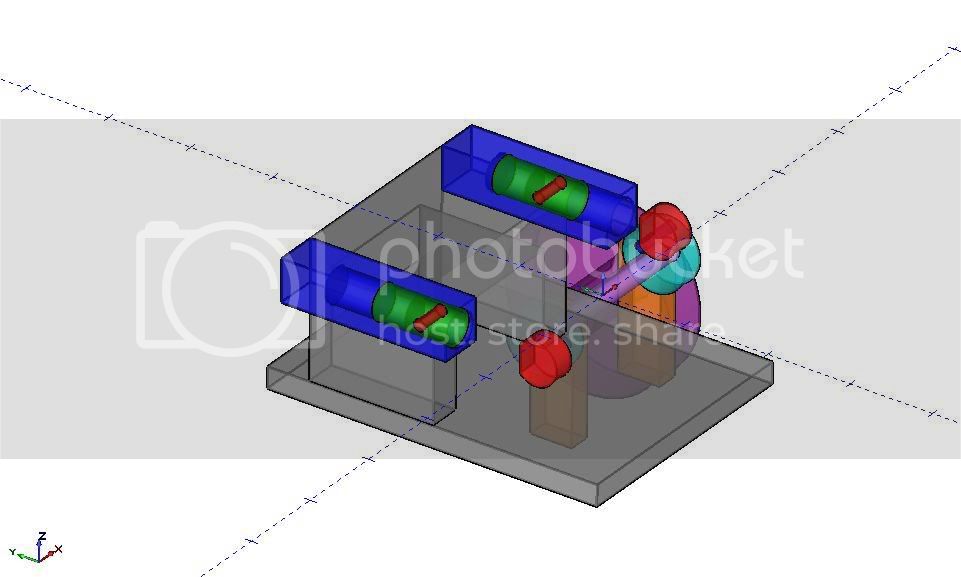

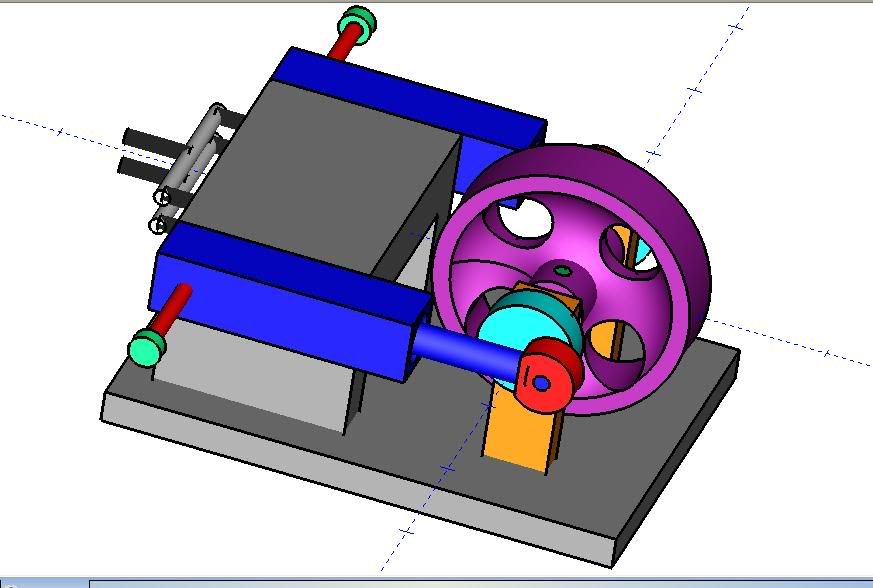

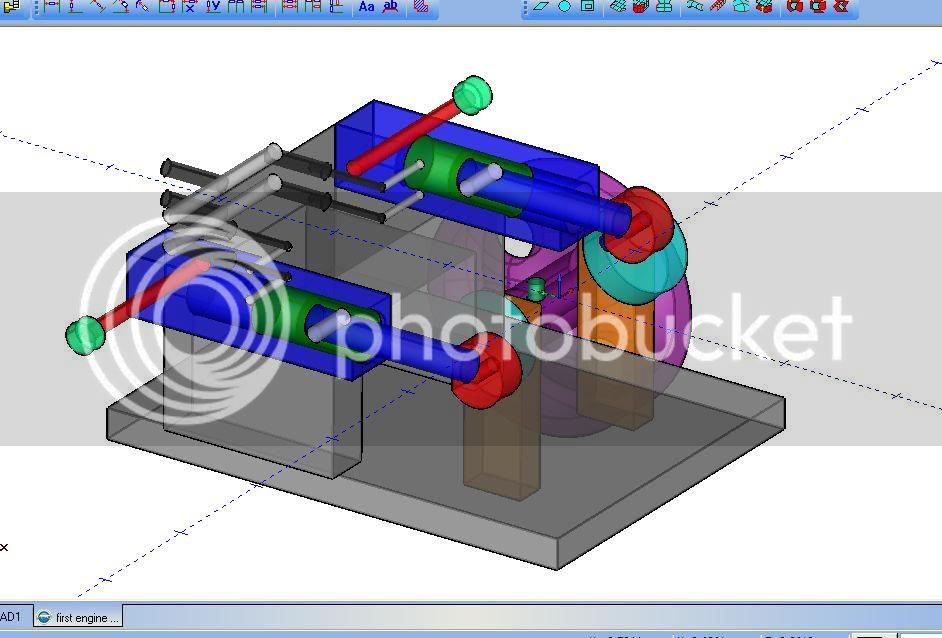

and where I am at the moment............

So to recap, I am a novice engineer, a novice Cad user and a novice designer. Should be an interesting ride!

Anyway copyright accepted as the design will be worth a fortune...so its free if it works and for sale if it doesn't...Have I got that right? Anyway a few images to show where I am. Advice and constructive criticism welcome.

and where I am at the moment............