Paul,

I have a few views on model finishes, and they maybe don't coincide with yours.

Because of the reduction in scale, it would be very difficult to produce the exact flame cut patterns of heavy engineering, so I personally would reproduce the model to look like a 'perfect' version, otherwise you could have it ending up looking like a ragbag model, where it looks like you couldn't be bothered to finish it. I think it is called artistic license.

Of course, if it was going for display as an exact copy, and lots of pictures of the original were shown, featuring the very rough finishes, then I don't know how I personally would cope with it, as I have never had to do that. A very difficult decision on your part, and I think, only you can make it.

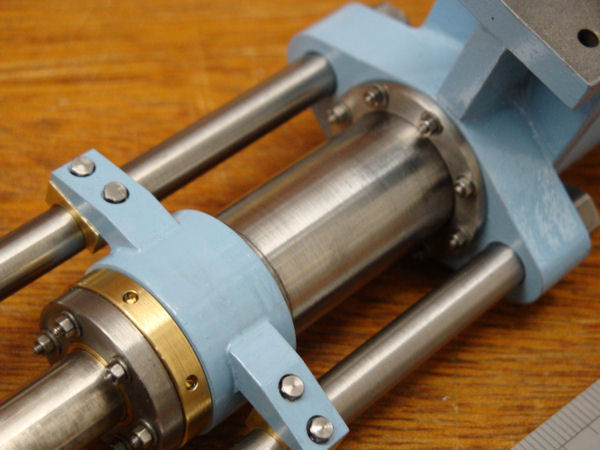

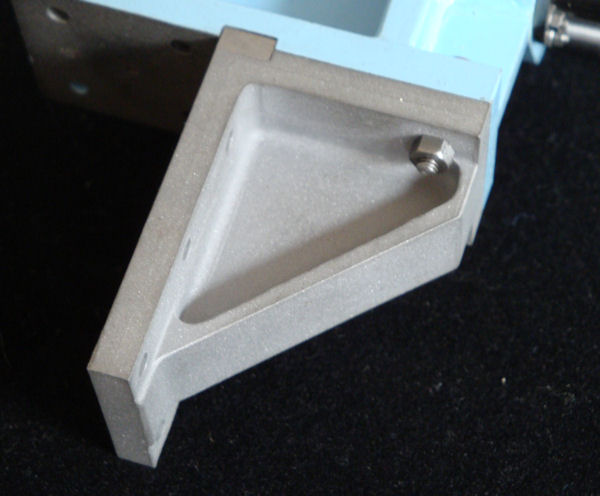

Now if things were a cast finish, I would try to replicate some sort of roughness on it, just to simulate the surface, say grit blasting the areas that weren't machined on the original. But very fine coats of paint need to be used as the effect would soon be lost.

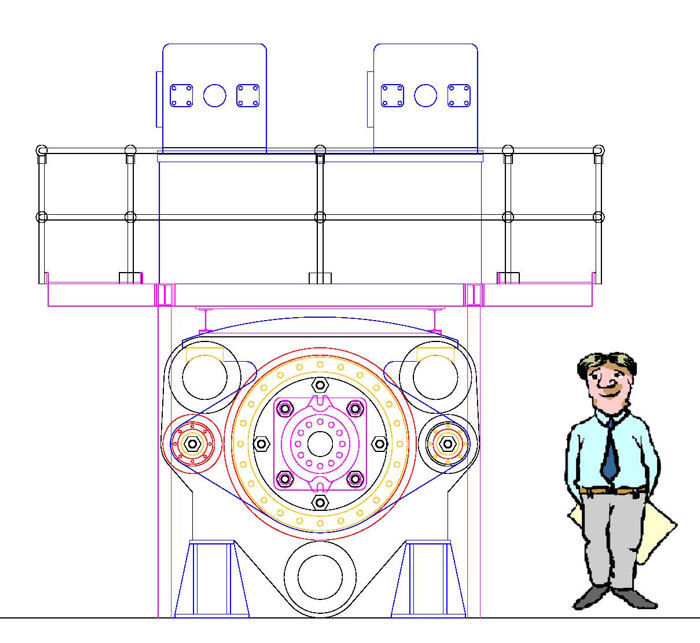

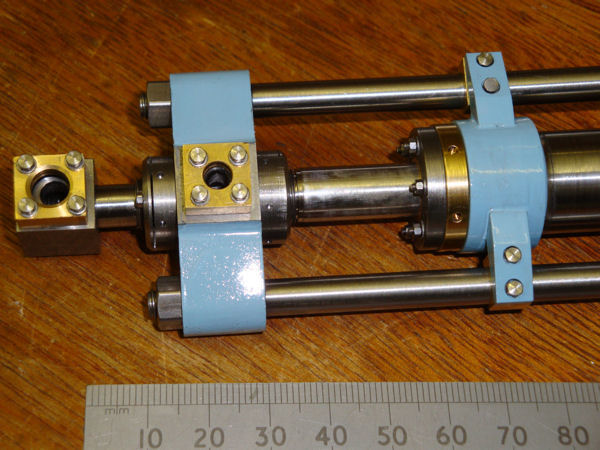

Just a few of my thoughts, and things are looking great up to now.

Bogs