- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

Chuck, that is good placement for your "Y"motor. Good thinking. On my conversion the pulley for the "Y" limits the travel a little, making parts with just over 8" in the "Y" impossible.

You may want to also check out the pulley size for the "Y" so this doesn't happen to you. You will want all the "Y" you can get.

maury

Thanks, Maury, the pulley on the Y-axis sticks out far enough that clearance isn't an issue.

Luc, thanks for the tip. I'll give that a try when I get the drivers and motors hooked up.

Shepdog, you're welcome to whatever drawings I have, although I don't know if they'll be any help to you unless your machine is substantially the same as mine...

The angular contact bearings came in the mail today so I spent the rest of the afternoon and evening getting those installed. Since I was installing the bearings in the original bearing block casting, I went very slowly and was very careful not to screw something up. I did have one close call... I was very near the final OD and decided to press the bearing in and see how it fit. It wasn't real tight, but getting it back out was a wooley booger! I did finally get it out and bored the opening a little bigger so it is a sliding fit with no slop.

I also installed a regular ball bearing on the motor end of the X-axis ball screw. All the feed thrust is on the other end of the table which has dual thrust bearings, so this end just needs to handle the radial force from the belt. Also, in addition to the set screw which holds the extension onto the Y-axis ball screw, I put some Loctite 620 on it and also pinned it with a roll pin.

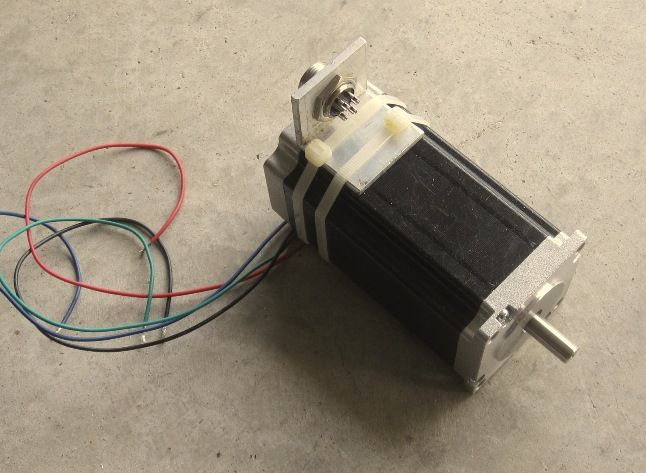

So, I ordered some connectors like these:

to connect the motors to the cables. I'm currently planning on using 4 conductor , 18 gauge stranded wire for the cables. Is that what most folks use? I'd like to use coiled cable like they used to use on telephone handsets, but have no idea where to find anything like that in the gauge I need. The other end of the cables want DB9 connectors for the Gecko G540.

Chuck