PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

Firstly I Would like to thank 90LX_NOTCH for pointing me in the right direction for the plans, as i didn't even know what this engine was called, i saw his profile pic, and when i noticed the 1/2 size one he made (smaller than a 1 cent piece) my jaw dropped, i just had to start making one, well been a busy day here so only managed to get 3 bits done, nothing special just standard turning

The Flywheel - just facing off the back down to size

now ready for the rapid indexer

The Piston Rod - just starting the marking out

just waiting for the final hole to be drilled

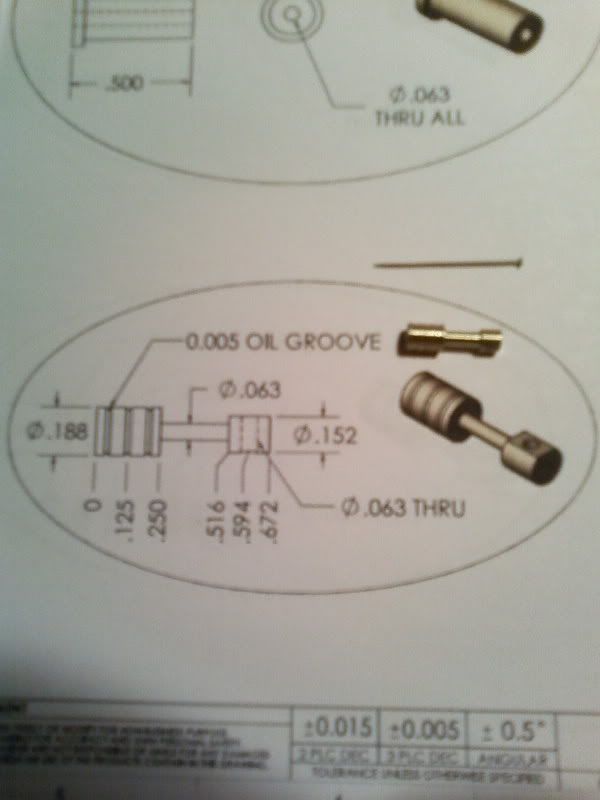

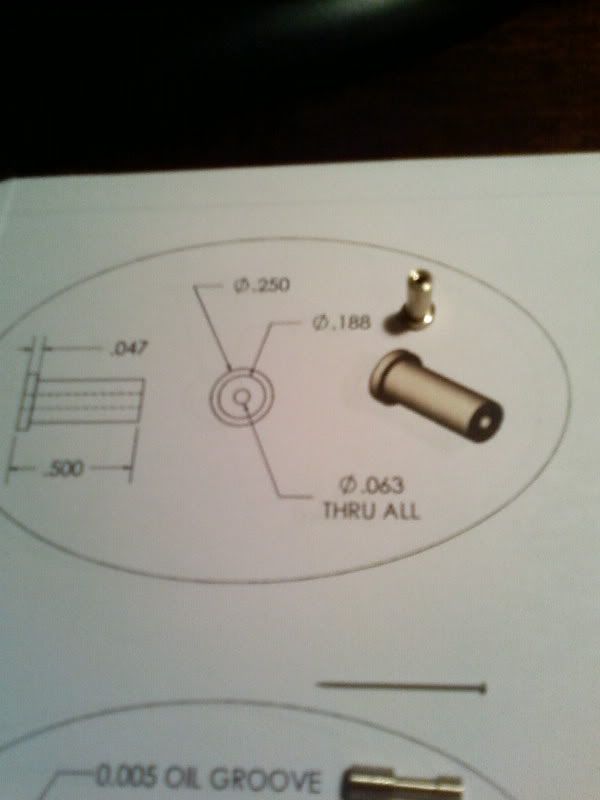

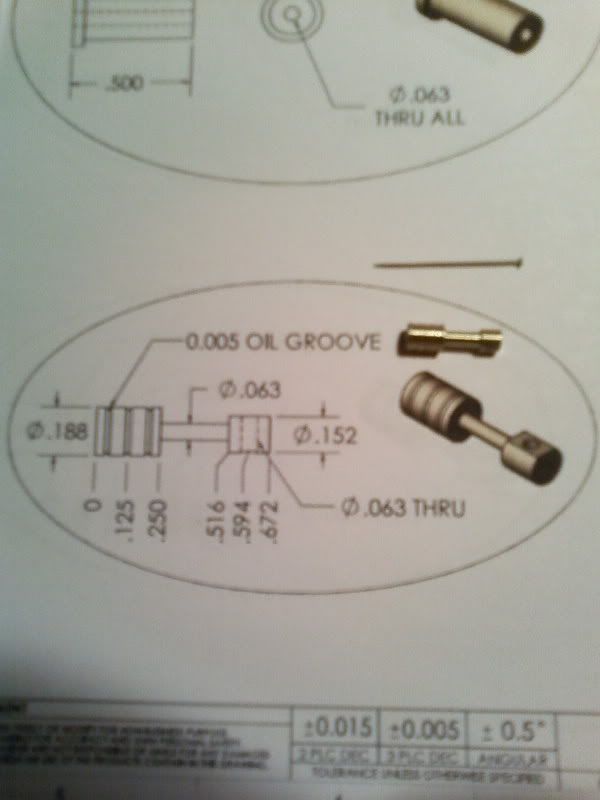

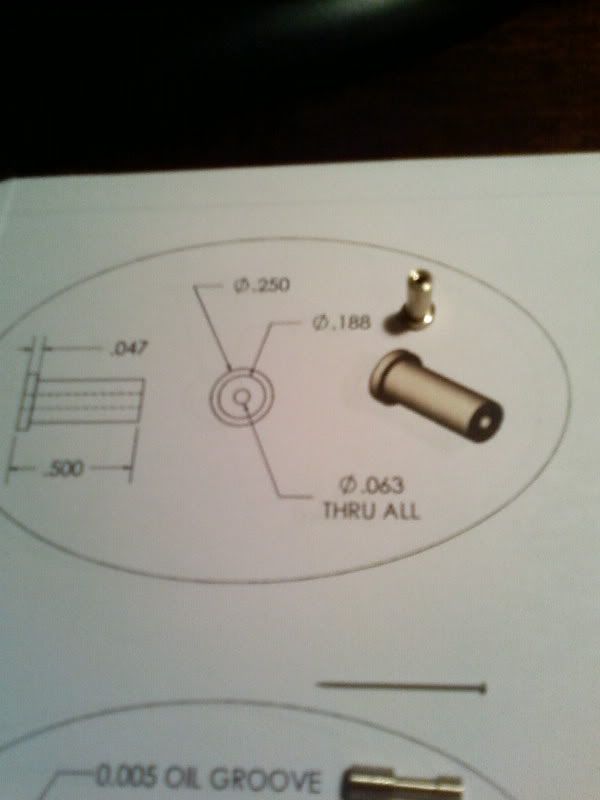

The Bearing - Center drilling the end before drilling

Drilled and done

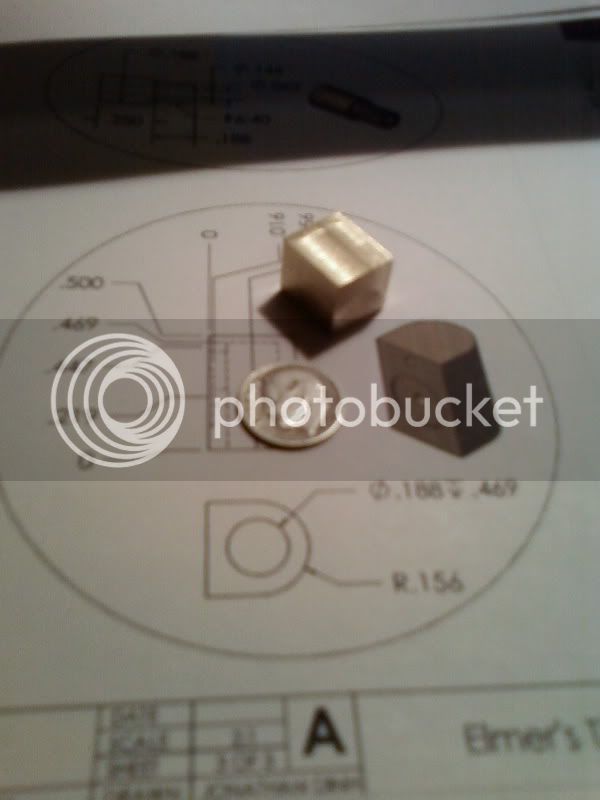

So, thus far

Hopefully I will get some time tomorrow to get some more done, if I do I will add more pics

This is my first attempt at this particular model and also at writing/filming a stage by stage,

hope it is good enough [nervous grin]

The Flywheel - just facing off the back down to size

now ready for the rapid indexer

The Piston Rod - just starting the marking out

just waiting for the final hole to be drilled

The Bearing - Center drilling the end before drilling

Drilled and done

So, thus far

Hopefully I will get some time tomorrow to get some more done, if I do I will add more pics

This is my first attempt at this particular model and also at writing/filming a stage by stage,

hope it is good enough [nervous grin]