zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

PhiberOptix said:I am from a country that was writing dates before other country's were even discovered

I thought you were from the UK. :big:

PhiberOptix said:I am from a country that was writing dates before other country's were even discovered

Quote from: craynerd on August 24, 2009, 06:18:22 PM

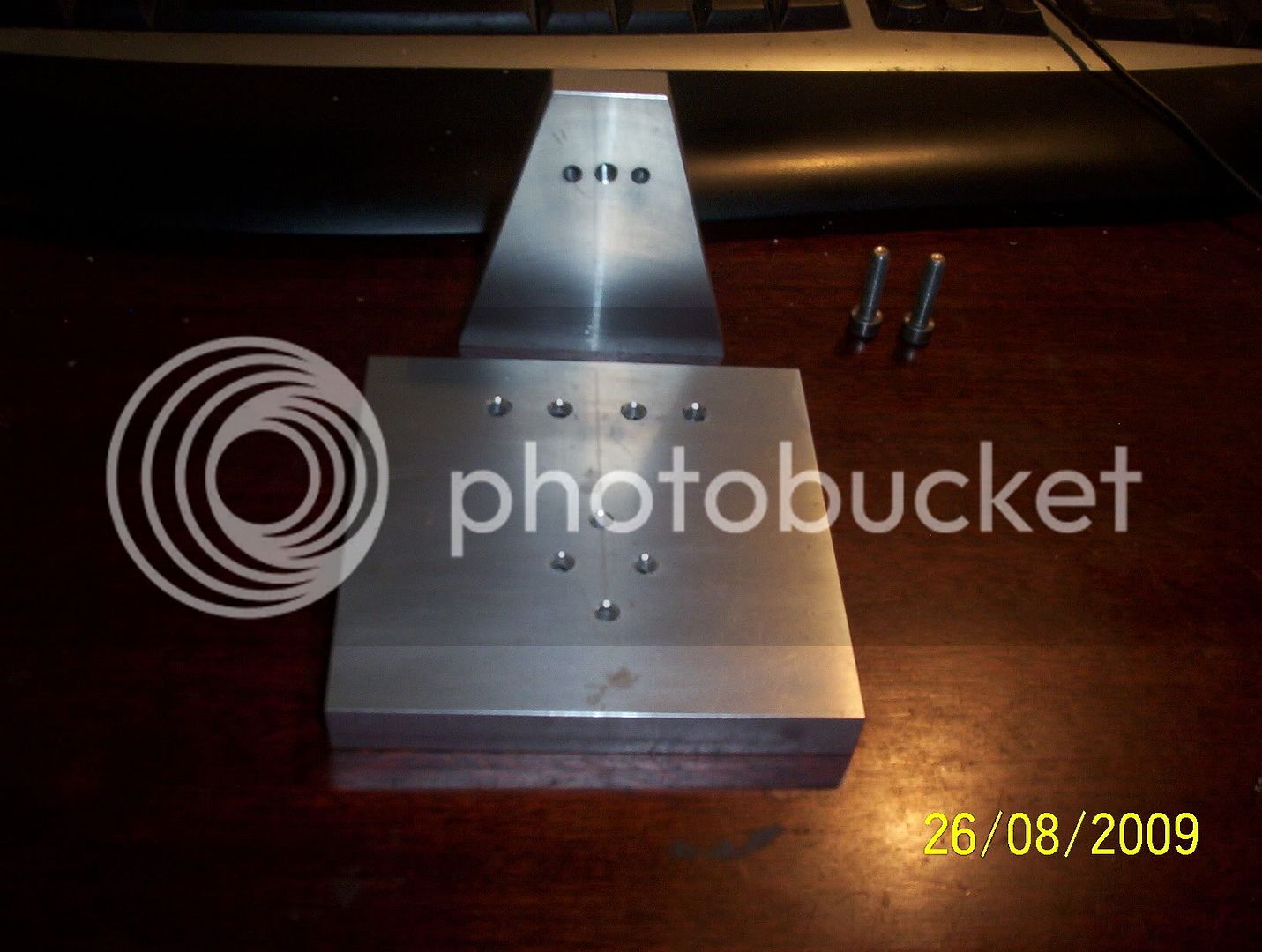

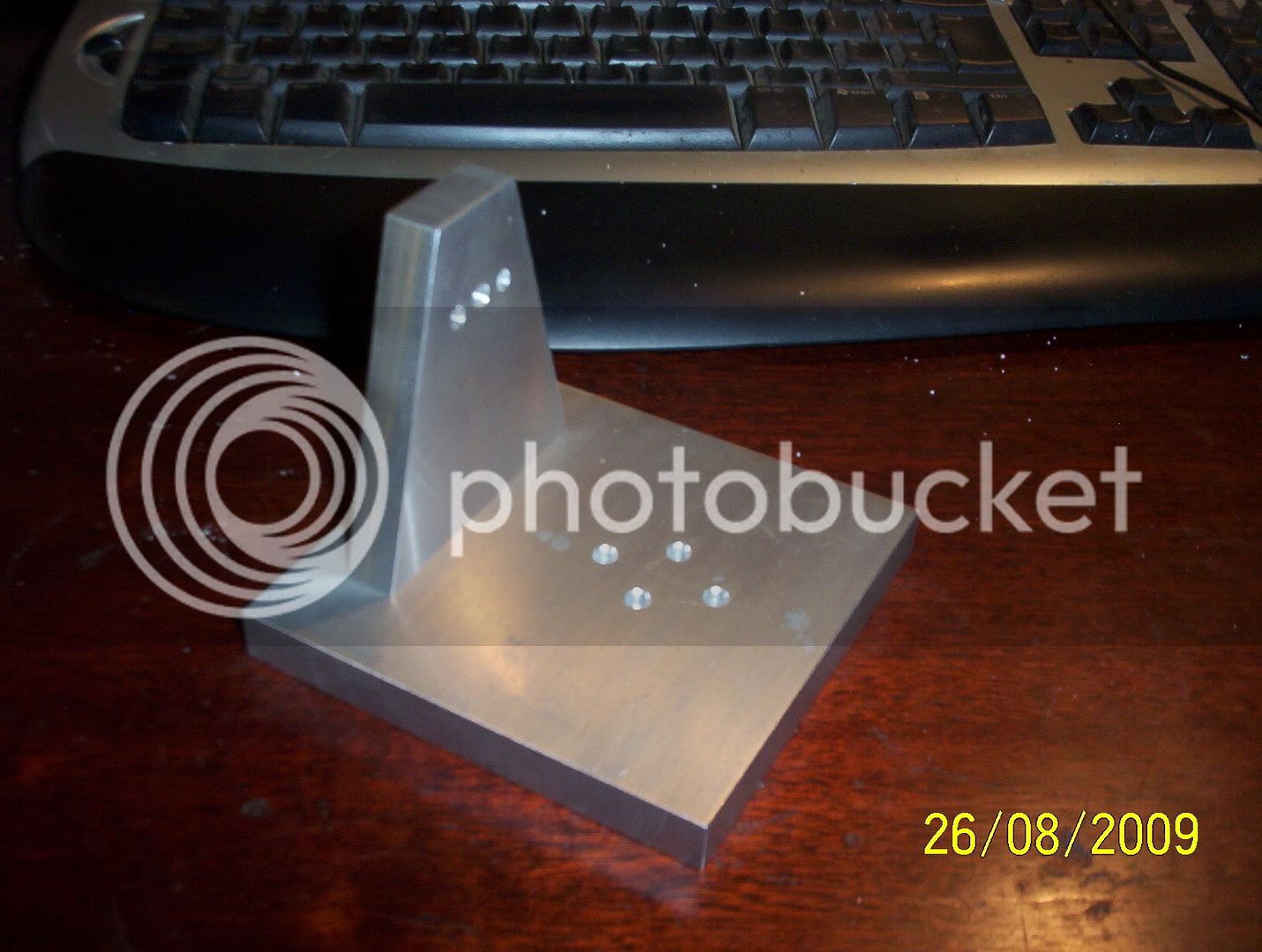

If you look at Stews design, he has also added an additional valve port block on the vertical support and this seems to work well yet is not shown in the original plans.

The other valve port is built into the flywheel post in the plans I have

SBWHART said:Hi Andy

I noticed you've got an RT under your mill that will make production of the cylinders and ports a doddle.

SBWHART said:Interesting that your using a 3 in 1 my machine is the Chesters version of the same machine, you can do a surprising amount of good work on them the biggest draw back is the rigidity of the mill and keeping swapping over,

RobWilson said:Very nice work Andy Thm: flywheel looks great. :bow:

Looks like your well tool'd up ;D

PhiberOptix said:...see all the drill holes OMG I guess they had the apprentice using this one...

Maryak said:Andy,

I'm with Rob. Where did you latch onto the magnetic table ???

Best Regards

Bob

PhiberOptix said:Today I did not get too much done had visitors again

kvom said:I don't know much about the 3-1 machines, but I'm wondering why the new vise is along the ways rather than across. Engine is coming along nicely.

Enter your email address to join: