PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

WhoooHooooo look what arrived last night

the bronze offcut to make the replacement cylinder

also working on a saddle stop/mount for an X axis dro

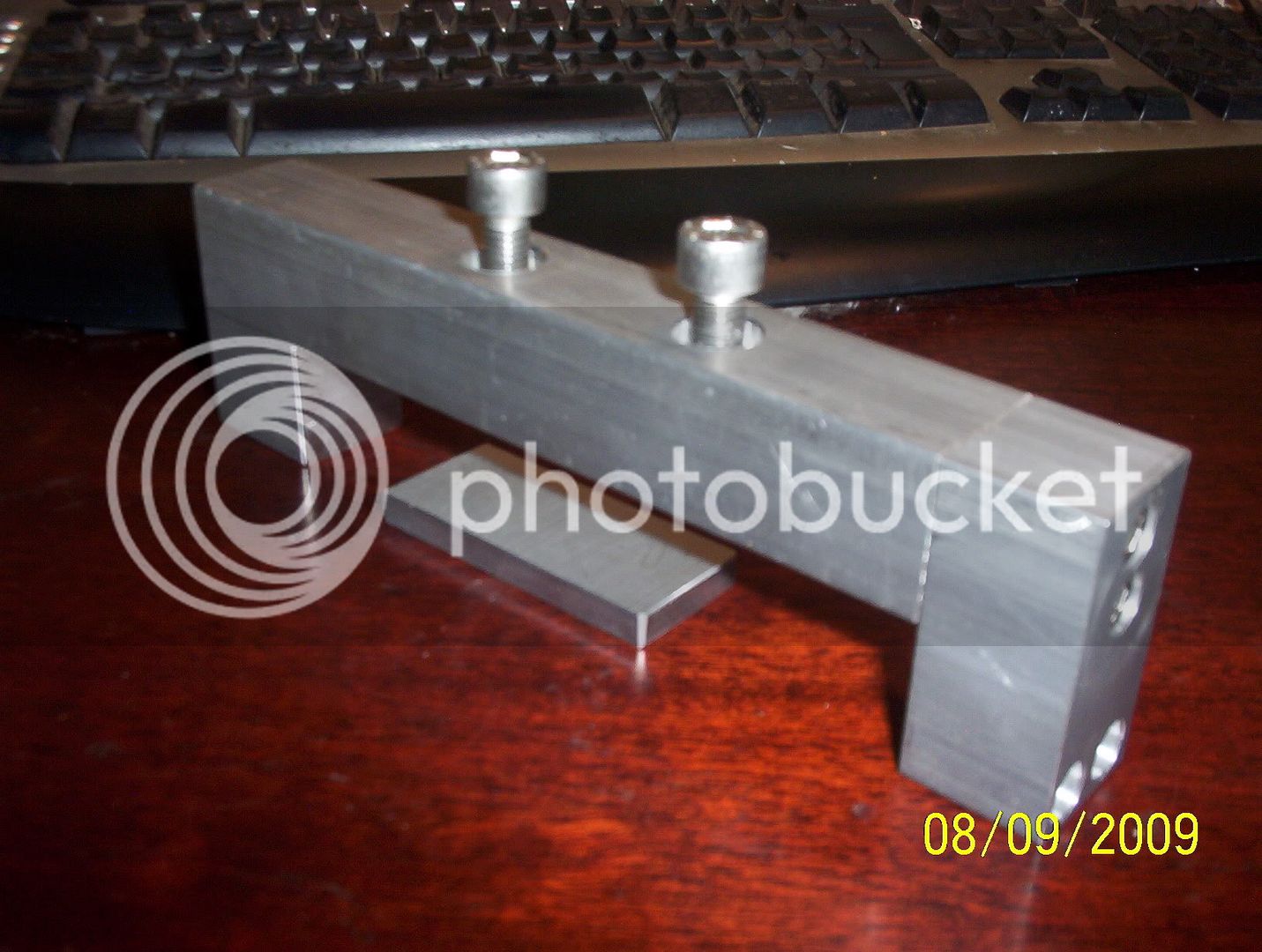

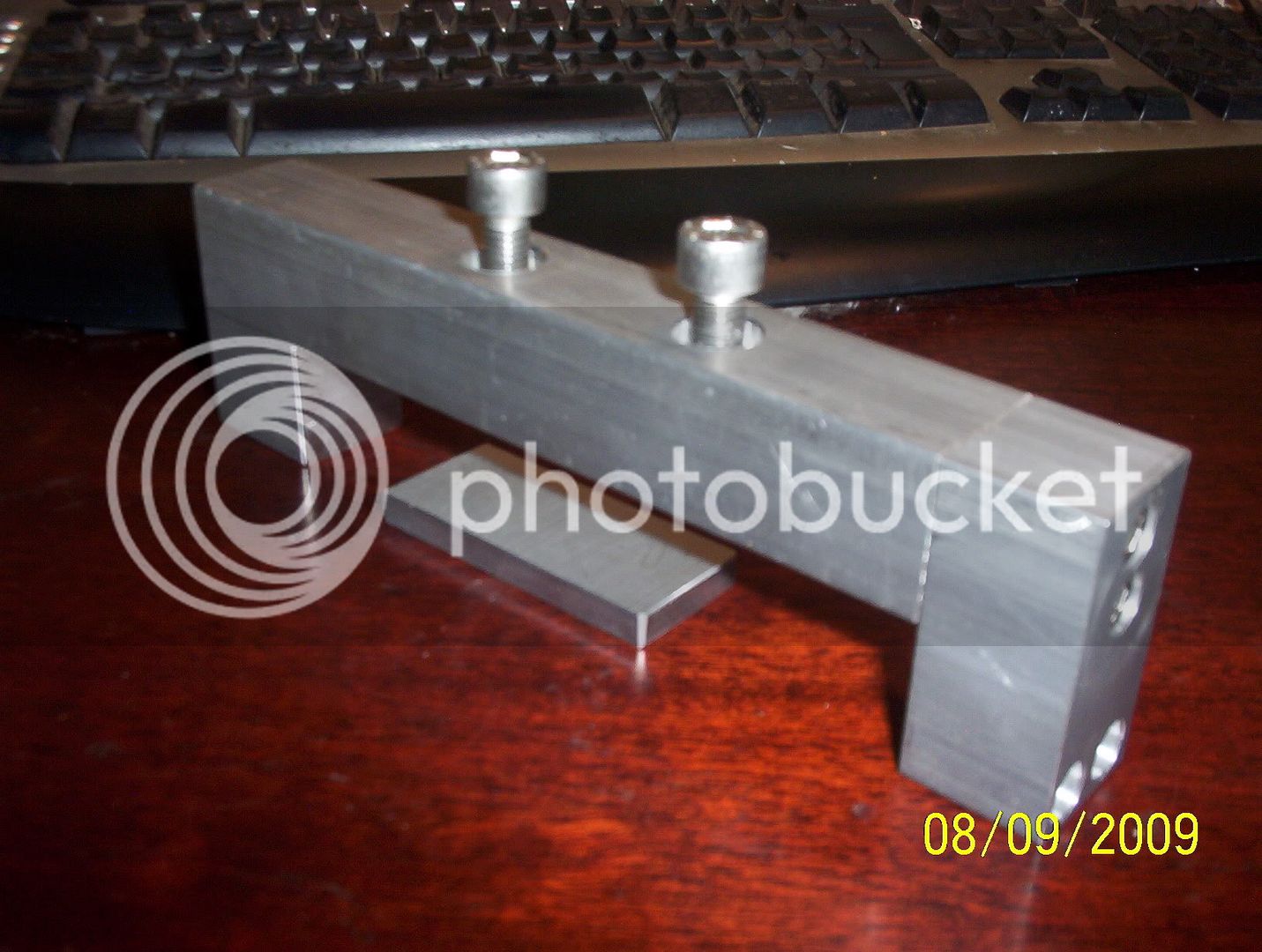

and the start of a machine vice

as I am already set up for milling i will do some more on the vice first then change over to turning mode do the cylinder and pins for the vice and I want to use round bar on the stop in place of Chamffers then put the rapid indexer on and over into drill mode finish the cylinder

tomorrow I want to make a jig by cutting a 45 degree vee along two edges of a right angle block of aluminium

I plan to use the block by clamping one end o a piston in one vee heat up the middle of the piston bend it into the second vee and clamp in situ til cool and see if that gives me the required 90 degree angle on the piston

the bronze offcut to make the replacement cylinder

also working on a saddle stop/mount for an X axis dro

and the start of a machine vice

as I am already set up for milling i will do some more on the vice first then change over to turning mode do the cylinder and pins for the vice and I want to use round bar on the stop in place of Chamffers then put the rapid indexer on and over into drill mode finish the cylinder

tomorrow I want to make a jig by cutting a 45 degree vee along two edges of a right angle block of aluminium

I plan to use the block by clamping one end o a piston in one vee heat up the middle of the piston bend it into the second vee and clamp in situ til cool and see if that gives me the required 90 degree angle on the piston