PhiberOptix

Well-Known Member

- Joined

- Jul 29, 2009

- Messages

- 146

- Reaction score

- 1

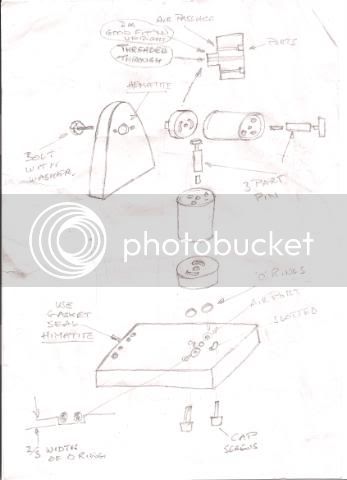

I have found another engine that I would like to build, called an Elbow Engine,

apparently it was all the fad a while back on here, but I haven't made one

and I like the concept so let get the preliminaries done

Locate the materials I need for the engine and mark them up ready for sawing

at this point I did not have anything close to 4 inch round bar for the fly wheel

I was going to cut a slice off some 4 inch square ally and turn it down in a 4 jaw

but I was given an off cut from my friends work place which made life easier

I also have materials in here to be cut down for other projects saddle stop,

chasis for three other engines ooh and a hex lighter (yes im going to be busy)

here is the materials ready for cutting minus the pistons and fly wheel which

I didn't have when this photo was taken

Cleaning up the freebie offcut, this will become the flywheel in time

note to self :- set the date on camera !!

Parts so far, (less pistons) with saw marks etc all cleaned up ready for machining

down to size tomorrow

.

apparently it was all the fad a while back on here, but I haven't made one

and I like the concept so let get the preliminaries done

Locate the materials I need for the engine and mark them up ready for sawing

at this point I did not have anything close to 4 inch round bar for the fly wheel

I was going to cut a slice off some 4 inch square ally and turn it down in a 4 jaw

but I was given an off cut from my friends work place which made life easier

I also have materials in here to be cut down for other projects saddle stop,

chasis for three other engines ooh and a hex lighter (yes im going to be busy)

here is the materials ready for cutting minus the pistons and fly wheel which

I didn't have when this photo was taken

Cleaning up the freebie offcut, this will become the flywheel in time

note to self :- set the date on camera !!

Parts so far, (less pistons) with saw marks etc all cleaned up ready for machining

down to size tomorrow

.