Aloha Brian and company :

Thanks so much for sending up a flare to the Hemingway folks...I still have the money set aside for the grinder but I may squander it soon on going to see a Rolling Stones concert in Las Vegas. Might be my last chance while Mick and I are still on the right side of the dirt.

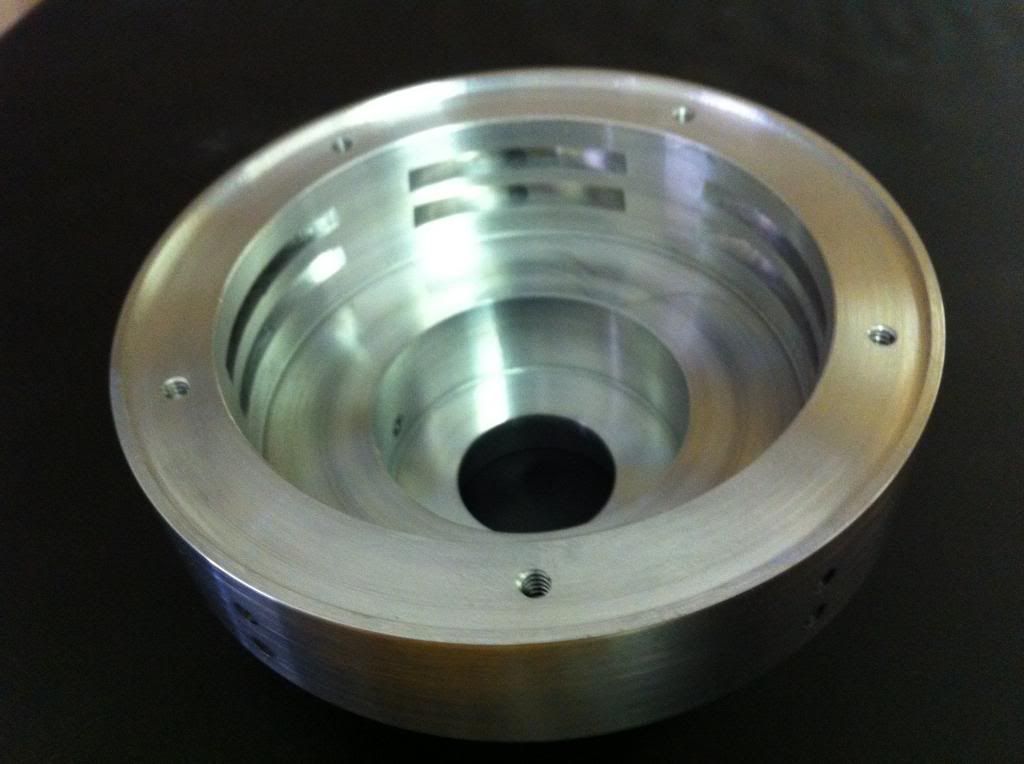

My little assembly cradle (this week's modest project) is done, and seems practical:

and, from the other side...

The motor mounts are pretty obvious, just carved out of 1/2" square ali; the circular mount is milled out from a 5" diameter 7075 billet, and the leftover center piece was used as the actual base mount (screwed to a Home-Depot-bought piece of 17" dia. circular piece of 3/4" ply), with a 3 1/2" length of stainless 1/2" dia. in between, screwed into the ali circle, and just sitting inside the 1/2" reamed center of the base mount. It seems secure, and rotates easily whenever shoved.

Glad your trip went well, Brian, and I hope it concludes safely and successfully. "Those heads" are waiting, and I'm a little envious...if for no other reason than, when I'm able to get my teeth into them, it'll mean that that *$@# crankshaft will be behind me...as it is that slab of tool steel is just laying there grinning at me, and I don't know if I'm at all equal to the task.

If not, I suppose there's more steel in the world.