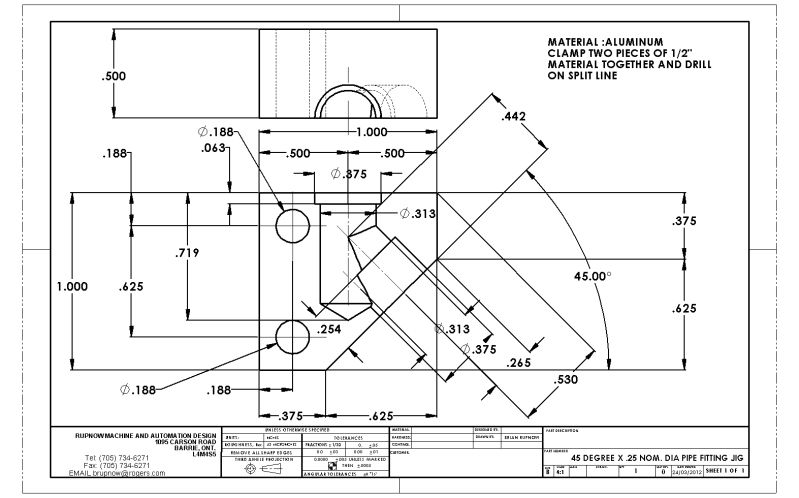

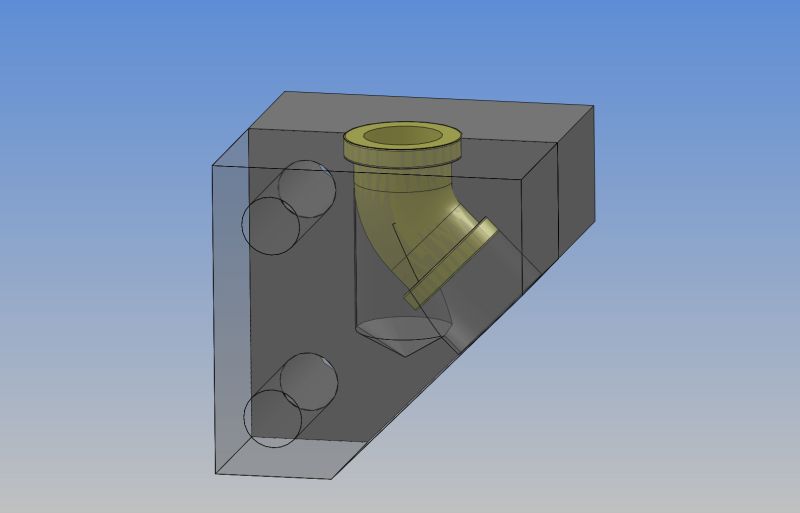

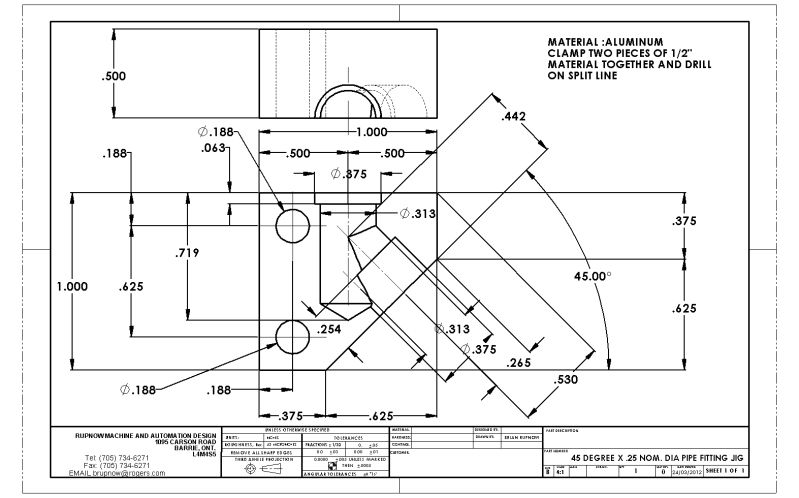

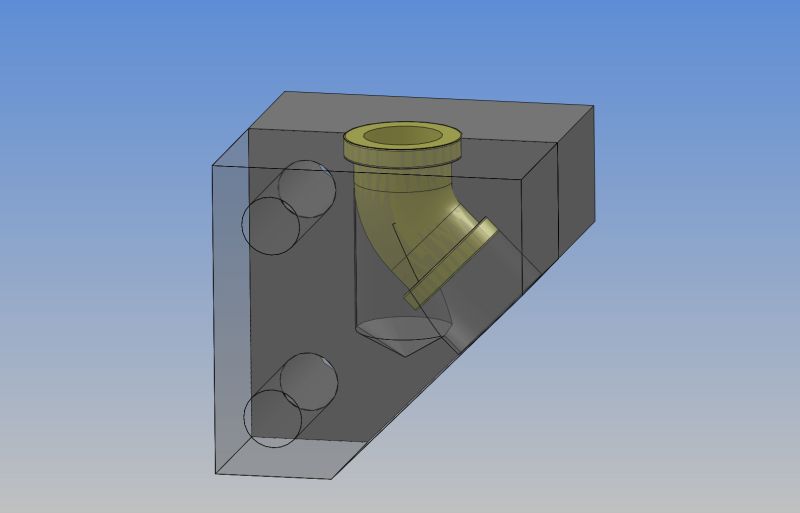

Earlier this week I fabricated and used a simple drill jig designed by MetalButcher to machine and drill some 1/4" x 90 degree PM Research elbows. It worked very well, and now I am faced with doing the same machining and drilling/tapping some 45 degree x 1/4" elbows. I have put together a quick and nasty jig drawing so I can do my 45 degree elbows now. Unfortuanately this jig will allow me to do only one side of the elbow, then I will have to open the jig and flip the elbow around to do the other end. There are reasons why it is like this, mostly having to do with the fabrication of the jig itself. I will make one according to this drawing and show you my results.-----Brian